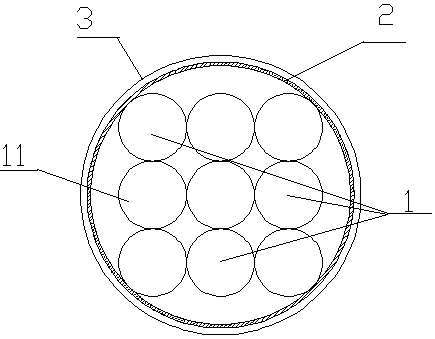

A three-layer composite marine rope and its manufacturing method

A production method and layer compounding technology, applied in the field of ropes, can solve the problems of affecting the service life, wear and damage of ropes, and corrosion of cables, etc., and achieve the effects of energy saving, long service life and reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using the method described in the present invention to make a marine rope with a specification of 100mm, it is specifically realized through the following steps:

[0026] 1) Twist 240 bundles of 1500D HMPE fibers into twisted yarns, and at the same time perform the first-level coating treatment. The twist is weak twist, and the twist direction is divided into S and Z directions. The solid content of the coating glue solution is 4%. The drying temperature is 40°C, and the drying time is 10 minutes;

[0027] 2) According to the different twist directions of the strands, weave the strands in a specific way, the number of spindles is 12, and the pitch is between 300mm-320mm;

[0028] 3) Carry out the second-level tensioned water-based amino resin coating on the braided sub-rope, the solid content of the coating glue solution is 15%, the oven temperature is 60°C, and the drying time is 30 minutes. After two-stage coating treatment, the sub-rope The final glue rate of the ro...

Embodiment 2

[0032] Using the method described in the present invention to make a marine rope with a specification of 140mm, it is specifically realized through the following steps:

[0033] 1) Twist 350 bundles of 1500D HMPE fibers into twisted yarns, and at the same time carry out the first-level coating treatment. The twist is weak twist and the twist direction is divided into S direction and Z direction. The drying temperature is 60°C, and the drying time is 15 minutes;

[0034] 2) According to the different twist directions of the rope strands, weave the rope strands in a specific way, the number of spindles is 8 spindles, and the pitch is between 300mm-320mm;

[0035] 3) Apply the second level of tensioned water-based amino resin coating to the braided sub-rope. The solid content of the coating glue solution is 7%, the oven temperature is 40°C, and the drying time is 20 minutes. After two-level coating treatment, the sub-rope The final adhesive rate of the rope is 15%, and the diame...

Embodiment 3

[0039] Using the method described in the present invention to make a marine rope with a specification of 100mm, it is specifically realized through the following steps:

[0040] 1) Twist 120 bundles of 1500D HMPE fibers into twisted yarns, and at the same time carry out the first-level coating treatment. The twist is weak twist and the twist direction is divided into S direction and Z direction. The drying temperature is 50°C, and the drying time is 12 minutes;

[0041] 2) According to the different twisting directions of the strands, weave the strands in a specific way, the number of spindles is 12, and the pitch is between 220mm-240mm;

[0042] 3) Carry out the second-level tensioned water-based amino resin coating on the braided sub-rope. The solid content of the coating glue solution is 10%, the oven temperature is 50°C, and the drying time is 20 minutes. After two-stage coating treatment, the sub-rope The final adhesive rate of the rope is 18%, and the diameter of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com