Corner flue of CFB boiler and assembly process thereof

A flue and corner technology, which is applied in the field of CFB boiler corner flue and its assembly process, can solve the problems of unsatisfactory structural stability, time-consuming and labor-intensive assembly, and irregularities, so as to reduce the adjustment workload and benefit Use, ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

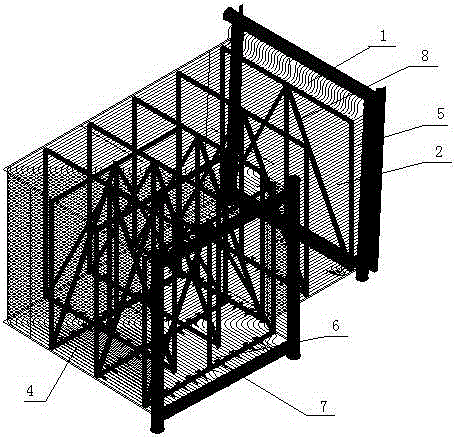

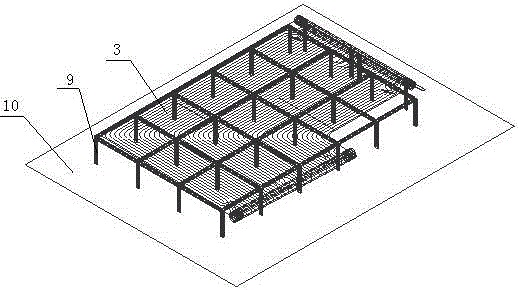

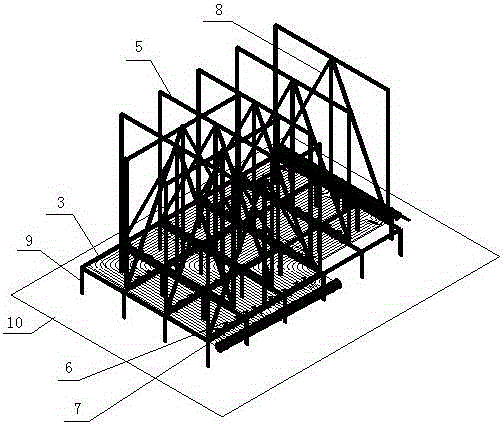

[0027] A CFB boiler corner flue, such as figure 1 , including the wall, the channel steel frame 5, and the positioning steel parts. The wall is an L-shaped wall made of a membrane wall, and a flue is formed on the inside of the wall, and the channel steel frame 5 is arranged on the inside of the wall and supports the wall. body, the membrane wall is composed of flat steel and the airtight tube panel welded by the pipe row, the flat steel is welded with positioning steel parts, the positioning steel parts include left positioning steel plate 6 and right positioning steel plate 7, left positioning steel plate 6 and right positioning steel plate The positioning steel plates 7 are respectively arranged on both sides of the channel steel frame 5 .

[0028] The channel steel frame 5 is provided with several diagonal braces 8, and the stability of the corner flue structure is further improved through the diagonal braces 8. Both the left positioning steel plate 6 and the right positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com