Detection method for strain hardening index n value of metal material

A technology of strain hardening index and metal materials, applied in the direction of testing the hardness of materials, etc., can solve the problems of not being widely used, poor fitting accuracy, cumbersome and other problems, and achieve the effect of reducing the detection workload and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

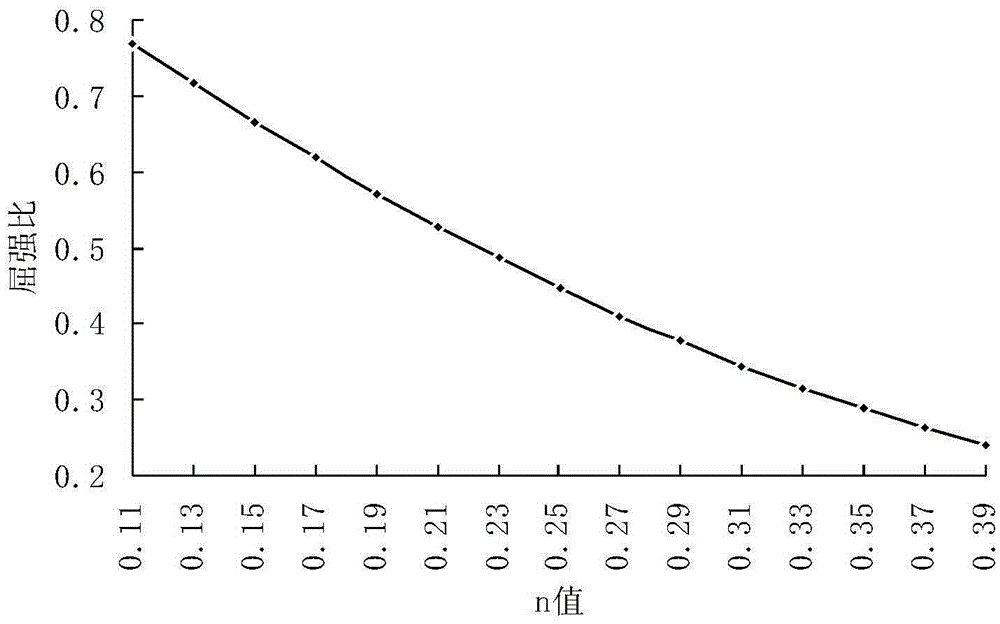

[0120] Calculation of strain hardening exponent n value of a DC06 cold-rolled steel plate

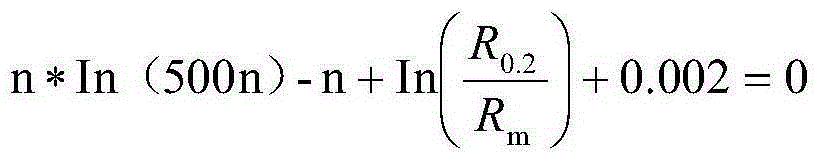

[0121] Taking a DC06 material with a thickness of 0.8mm as an example, its laboratory measurement results are shown in Table 1, and the relevant data in Table 1 are substituted into The C value of the DC06 material is solved as follows:

[0122] C=0.246×140÷302≈0.114

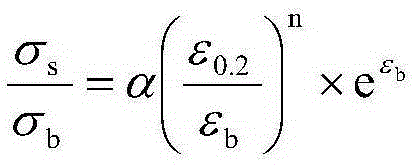

[0123] Then the corresponding relationship between the n value of the DC06 material and the yield strength and tensile strength is:

[0124] The yield strength, tensile strength and n 标 Value is standard value, with the n calculated by the above formula obtained by the present invention 测 For comparison, see Table 4 below:

[0125] Table 4 A certain DC06 material n 标 value and n 测 value comparison

[0126] σs / MPa

[0127] 123

[0128]It can be seen from Table 4 that the maximum relative error between the calculated n value of DC06 material and the standard value is -7.4%, the relative error i...

Embodiment 2

[0130] Calculation of strain hardening exponent n value of a DX54D galvanized sheet material

[0131] The measurement results of the mechanical property parameters of a 0.6mm thick DX54D material are shown in Table 3:

[0132] Substitute the relevant data in Table 3 into Solve the C value of the DX54D material:

[0133] C=0.2324×166÷295≈0.13

[0134] Then the corresponding relationship between the n value of the DX54D material and the yield strength ratio is:

[0135] The yield strength, tensile strength and n The marked value is the standard value, and the n calculated by the above formula obtained by the present invention 测 For comparison, see Table 5 below:

[0136] Table 5 A certain DX54D material n 标 value and n 测 value comparison

[0137] σs / MPa

[0138] It can be seen from Table 5 that the maximum relative error between the calculated n value of DX54D material and the standard value is 7.15%, the relative error is less than 5% in most cases, and the...

Embodiment 3

[0140] Calculation of strain hardening exponent n value of a st13 cold rolled steel plate

[0141] Taking a st13 material with a thickness of 0.5mm as an example, its laboratory measurement results are shown in Table 2.

[0142] Substitute the relevant data in Table 2 into The C value of the st13 material is solved as follows:

[0143] C=0.26×134÷294≈0.1185

[0144] Then the corresponding relationship between the n value of the st13 material and the yield strength and tensile strength is:

[0145] The yield strength, tensile strength and n 标 Value is standard value, with the n calculated by the above formula obtained by the present invention 测 For comparison, see Table 6 below:

[0146] Table 6 A st13 material n 标 value and n 测 value comparison

[0147] σs / MPa

[0148] 133

[0149] It can be seen from Table 6 that the maximum relative error between the calculated n value of st13 material and the standard value is 6.46%, the relative error is less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com