Automatic on-line diagnosis method for freight train coupler tail cotter position faults and system

A technology of coupler flat pins and freight trains, which is applied to the automatic online diagnosis of faults in the coupler pins of freight trains, and in the field of freight train fault diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

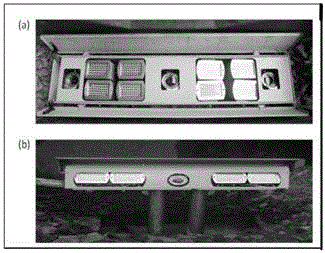

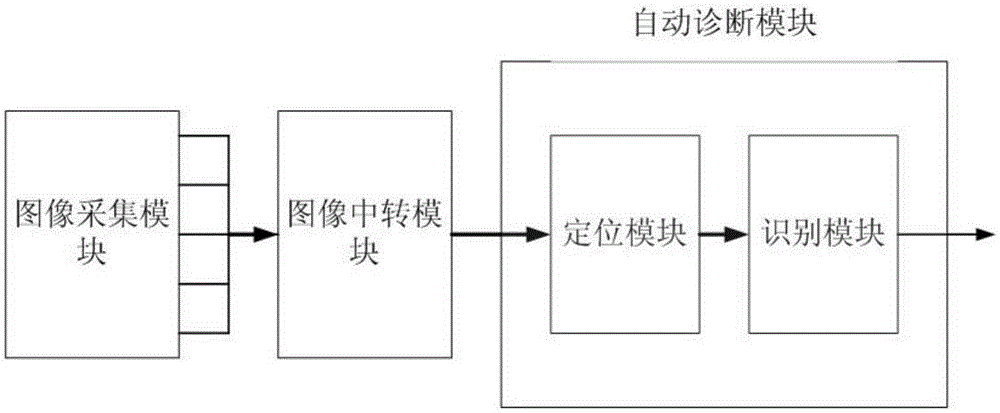

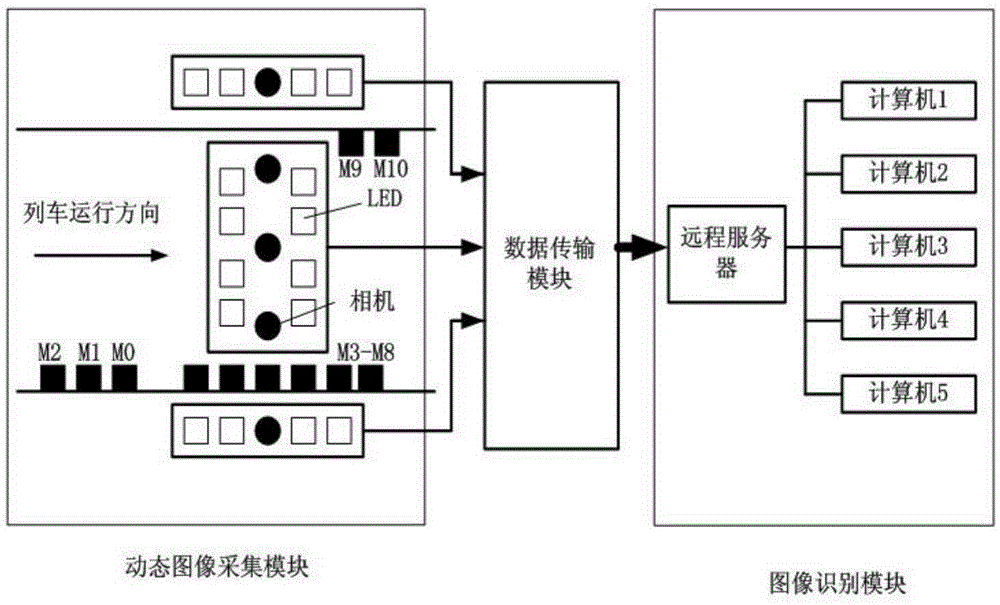

[0054] Such as figure 1 As shown, five high-speed cameras are installed in the automatic on-line diagnosis system of the freight train coupler flat pin position failure of the present invention to simultaneously capture the dynamic images of the moving train, and the whole diagnosis process is divided into two parts, the positioning part and the identification part . Since the high-speed camera is installed in the field, the imaging of the coupler pin may vary greatly due to different environmental conditions, so it is difficult to find existing mature features to represent the shape of the coupler pin. To solve this problem, a new type of feature called Multi-Dimensional Feature (MDF) is proposed. MDF contains features of 7 dimensions: normalized gradient magnitude and gradient histogram in 6 directions. In order to cope with the change of the scale of the hooktail pin in the image, a fast algorithm is also designed to calculate the multi-scale image features. This algorith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com