Electrically actuated rotary drive device

A rotary drive device, electrical manipulation technology, applied in the direction of transmission, electromechanical device, gear transmission, etc., can solve the problems affecting the compactness of the rotary drive device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

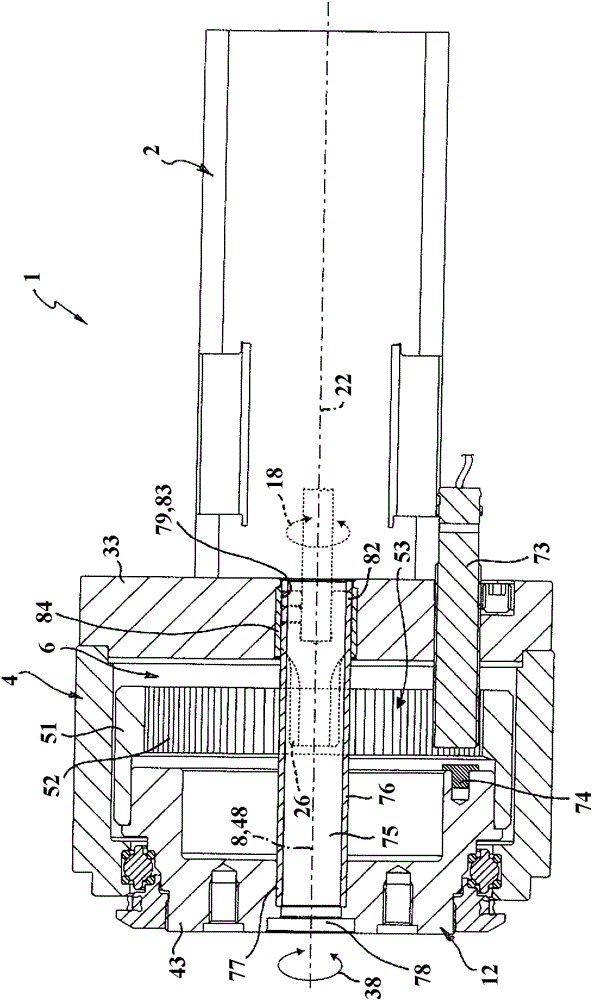

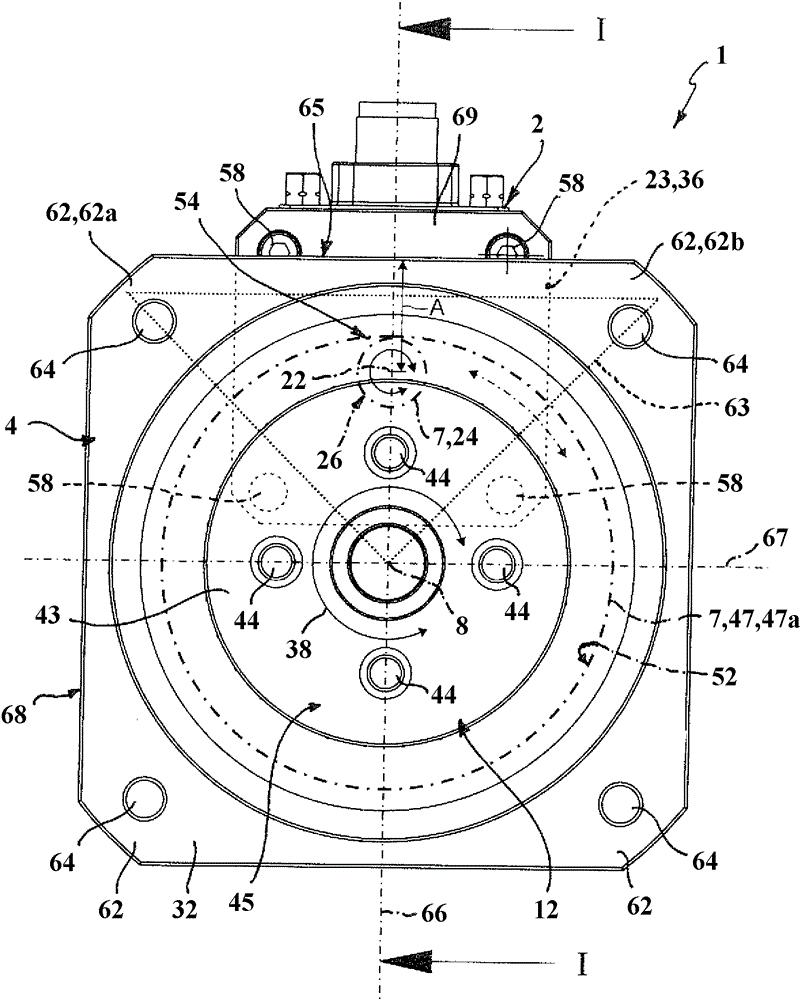

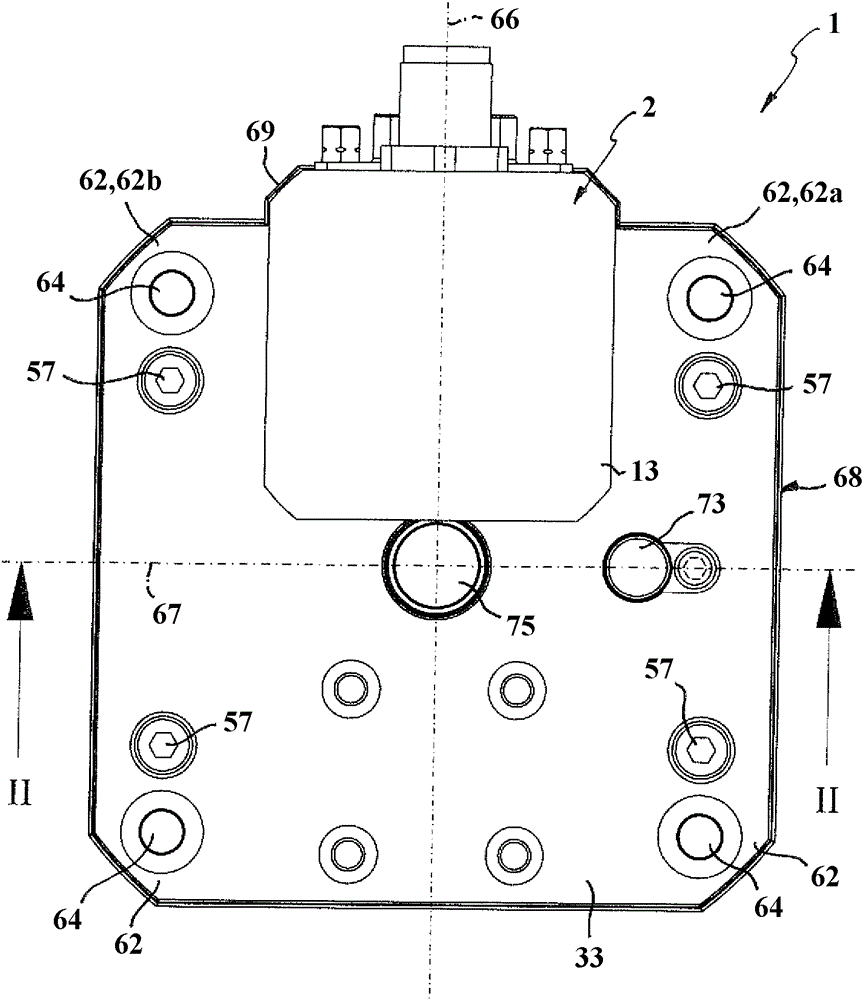

[0032] The electrically actuable rotary drive, which is designated in its entirety by the reference numeral 1 , has an electric drive motor 2 as a drive source, which is mounted on the rear side 3 b of the gear housing 4 of the rotary drive 1 . The gear housing 4 has an imaginary main axis 5 and a front side 3 a oriented opposite to the rear side 3 b , wherein both the front side 3 a and the rear side 3 b are oriented in the axial direction of the main axis 5 .

[0033]The gear housing 4 encloses an inner space which is referred to below as the gear chamber 6 . In this transmission chamber 6 there is a transmission part 7 of a gear transmission, which establishes a drive connection between the drive motor 2 and an output part 12 mounted rotatably about an axis of rotation 8 on the transmission housing 4 .

[0034] The axis of rotation 8 of the driven element 12 has the same orientation as the main axis 5 .

[0035] The electric drive motor 2 has a motor housing 13 which prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com