Method for arranging cooling for a component and a cooling element

A technology for cooling components and components, used in electrical components, printed circuit components, cooling/ventilation/heating retrofits, etc., can solve problems such as reducing lifespan, limiting maximum feeding power, etc., to reduce operating temperature, increase electrical power, and reduce The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following description, the embodiments are merely examples and a person skilled in the art can also put into practice the basic idea of the invention in another way than that described. Although an explanation may refer to an embodiment or embodiments in several places, this does not mean that the reference is to only one of the described embodiments or that a described feature is only useful in one of the described embodiments of. Separate features of two or several embodiments may be combined and thus form new embodiments of the invention.

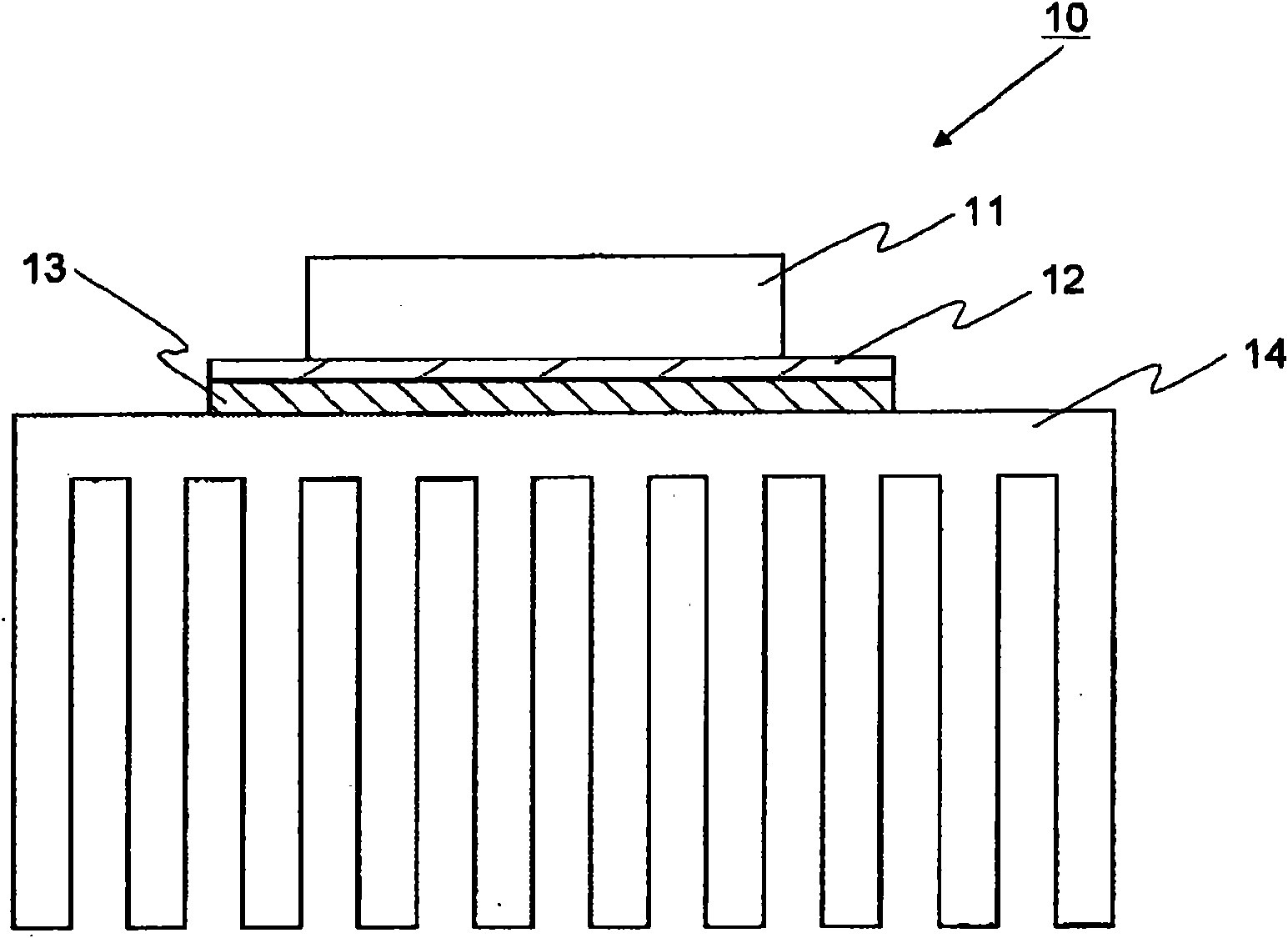

[0037] Figure 1 is presented in conjunction with the description of the prior art.

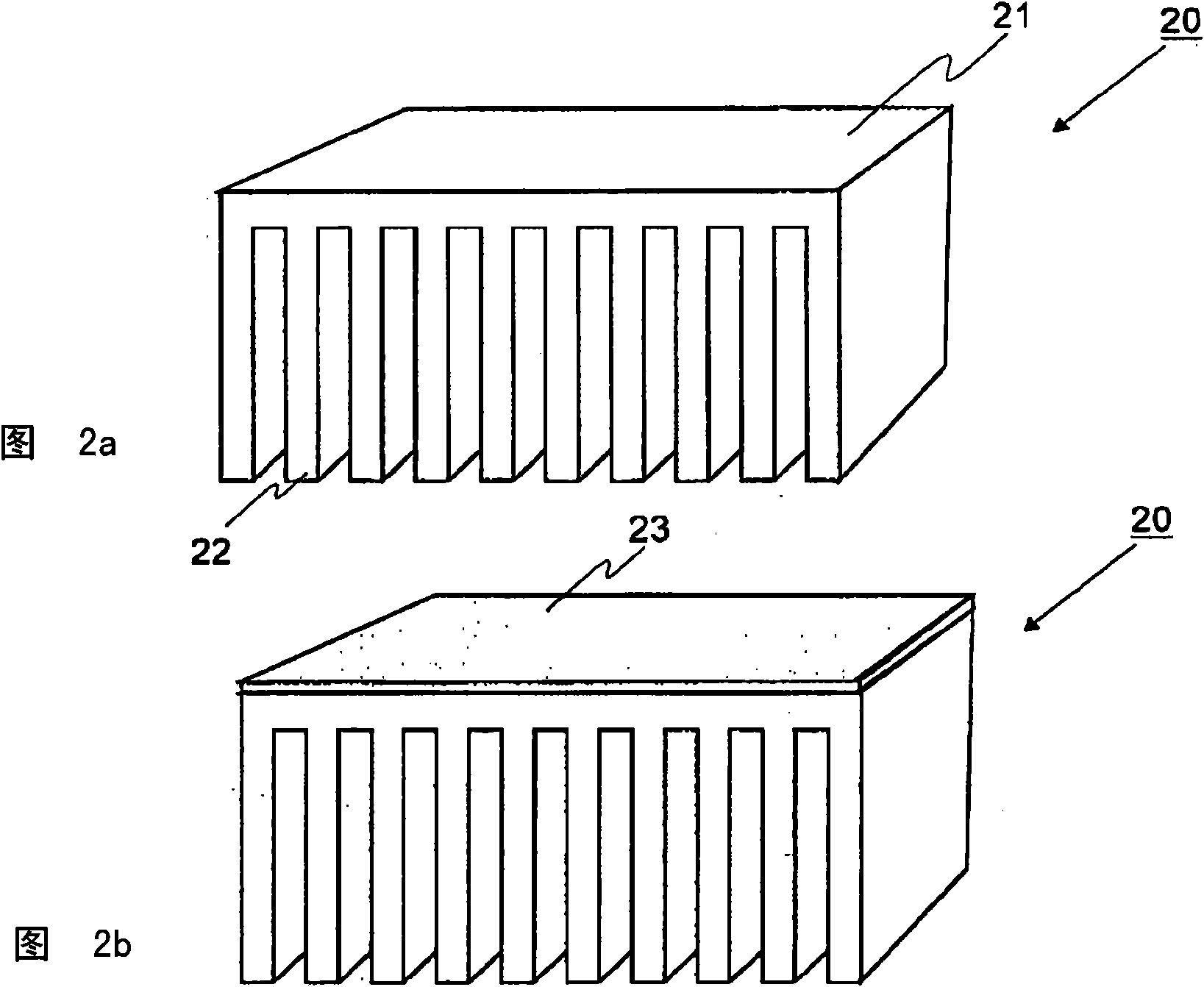

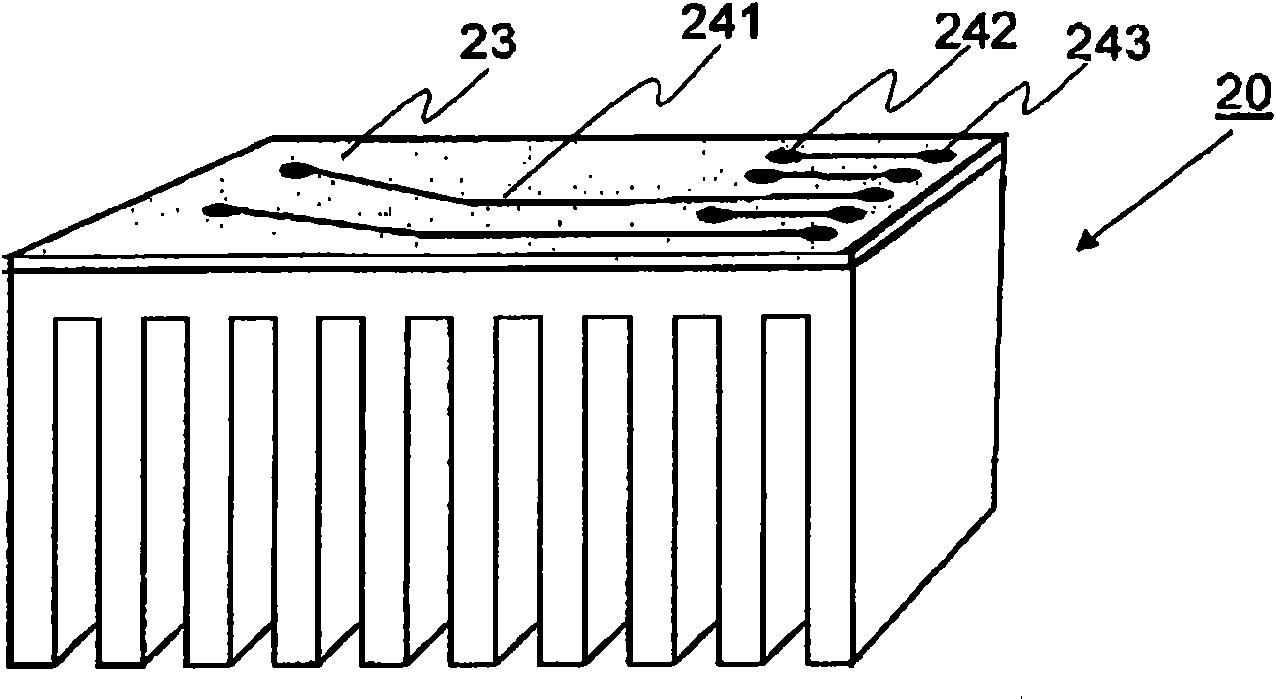

[0038] A circuit board or substrate supporting the electrical components is not necessarily required between the cooling element according to the invention and the electrical components fastened thereto. In the first stage of the construction method according to the invention, a thin layer of insulating material is formed onto the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com