Continuous flow photochemical reactor device

A chemical reactor and reactor technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as affecting reaction temperature, limiting application scope, and complex switching power supply connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

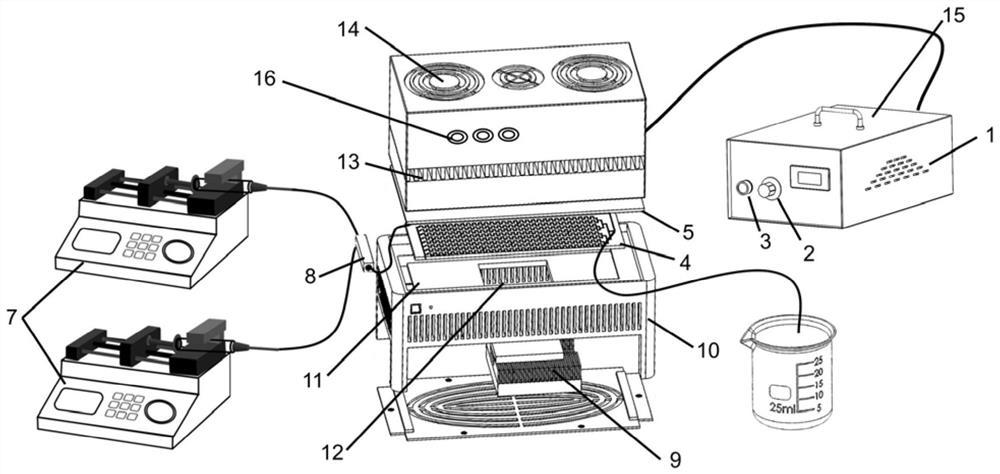

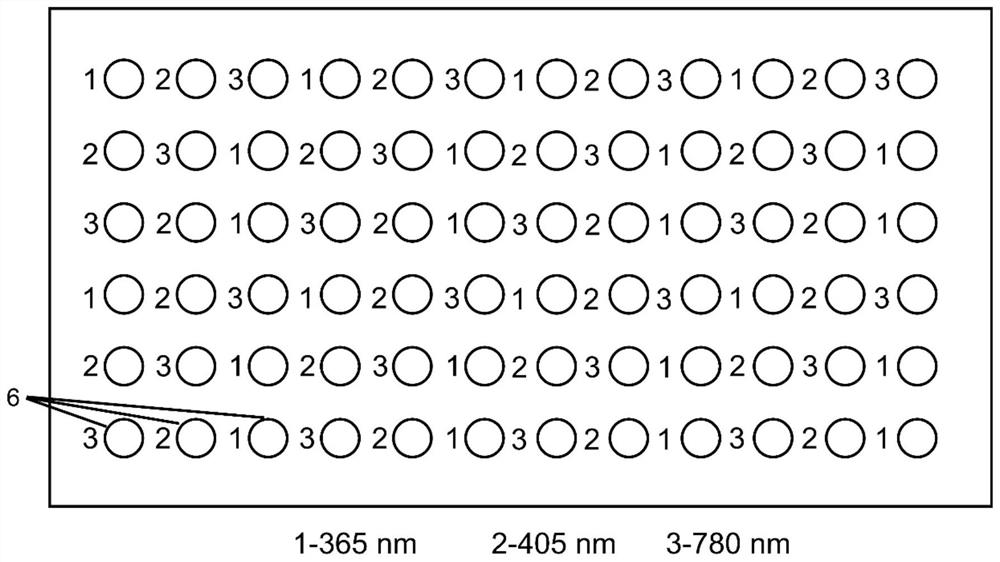

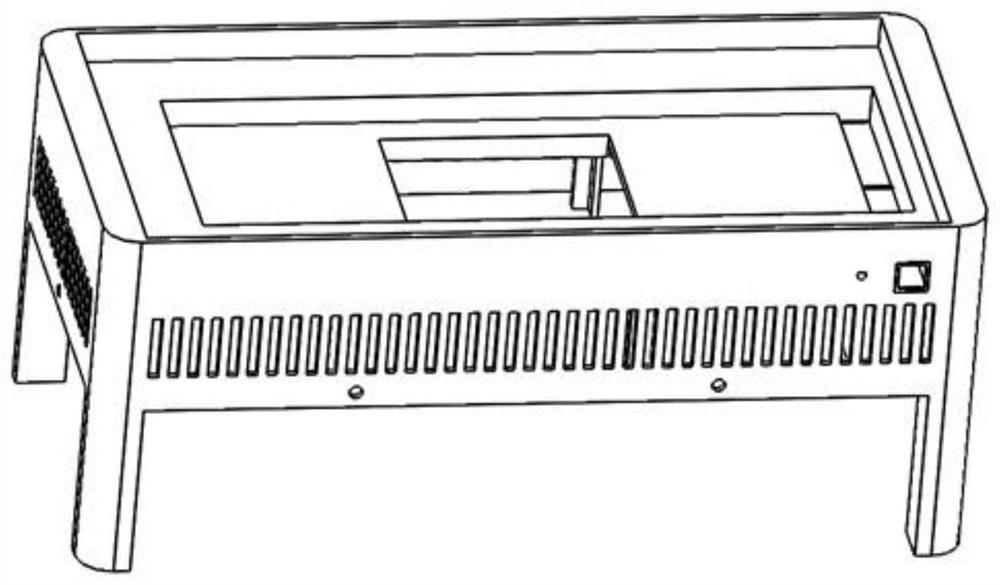

[0029] A continuous flow photochemical reactor device, including a light control unit, a reaction unit, and a temperature control unit; the light control unit includes an optical power regulator 1; the optical power regulator includes a sliding resistor, an adjustment knob 2, a control switch 3, and an AC power supply The AC input range of the AC power supply is 110-270V; the sliding resistor and the AC power supply are placed in the housing 15 of the optical power regulator, the adjustment knob and the control switch are arranged outside the housing of the optical power regulator, and the sliding resistor, The adjustment knob, the control switch, and the AC power supply are all electrically connected; the reaction unit includes a microreactor 4 and an LED lamp board 5; the LED lamp board is placed above the microreactor and connected in series with the sliding resistor and the AC power supply; The light board of the LED is composed of a plurality of LED lamp beads 6 arranged (...

Embodiment 3

[0039] Select the reaction of Example 2, keep the other conditions of the reactor, micro-mixer and micro-flow tube unchanged, adopt a three-wave mixed light source of 365nm, 405nm, and 780nm, press the control switch in the light control unit, and control the wavelength switch. The wavelength of the LED light board is required; the optical power density value is adjusted to 70mW / cm through the dimmer knob 2 ;Wavelength switch to change the wavelength, at a flow rate of 1000μL / min, the three wavelengths, when the retention time is 180s, the yields are 67%, 96%, 33%, respectively, indicating that the wavelength of the light source affects the catalytic effect of the photochemical reaction, 405nm is the optimum wavelength for this reaction.

Embodiment 4

[0041] Select the reaction of Example 2, keep other conditions such as the micro-mixer and the micro-flow tube unchanged, the fixed wavelength is 405nm, adjust the sliding resistor by adjusting the knob, and adjust to the optical power density value of 20mW / cm respectively 2 , 40mW / cm 2 , 70mW / cm 2 , 100mW / cm 2 , under the reaction condition of 1000μL / min flow rate, when the retention time is 180s, the reaction yields are 33%, 56%, 96%, 98%, respectively, indicating that the photochemical reaction yield increases rapidly with the increase of optical power density, Then it increases slowly with the increase of optical power density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Optical power density | aaaaa | aaaaa |

| Inner diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com