Gas and steam turbine installation and method for operating the same

A technology of steam turbines and gas turbines, which is applied in the direction of gas turbine devices, steam engine devices, jet propulsion devices, etc., and can solve problems such as large space locations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

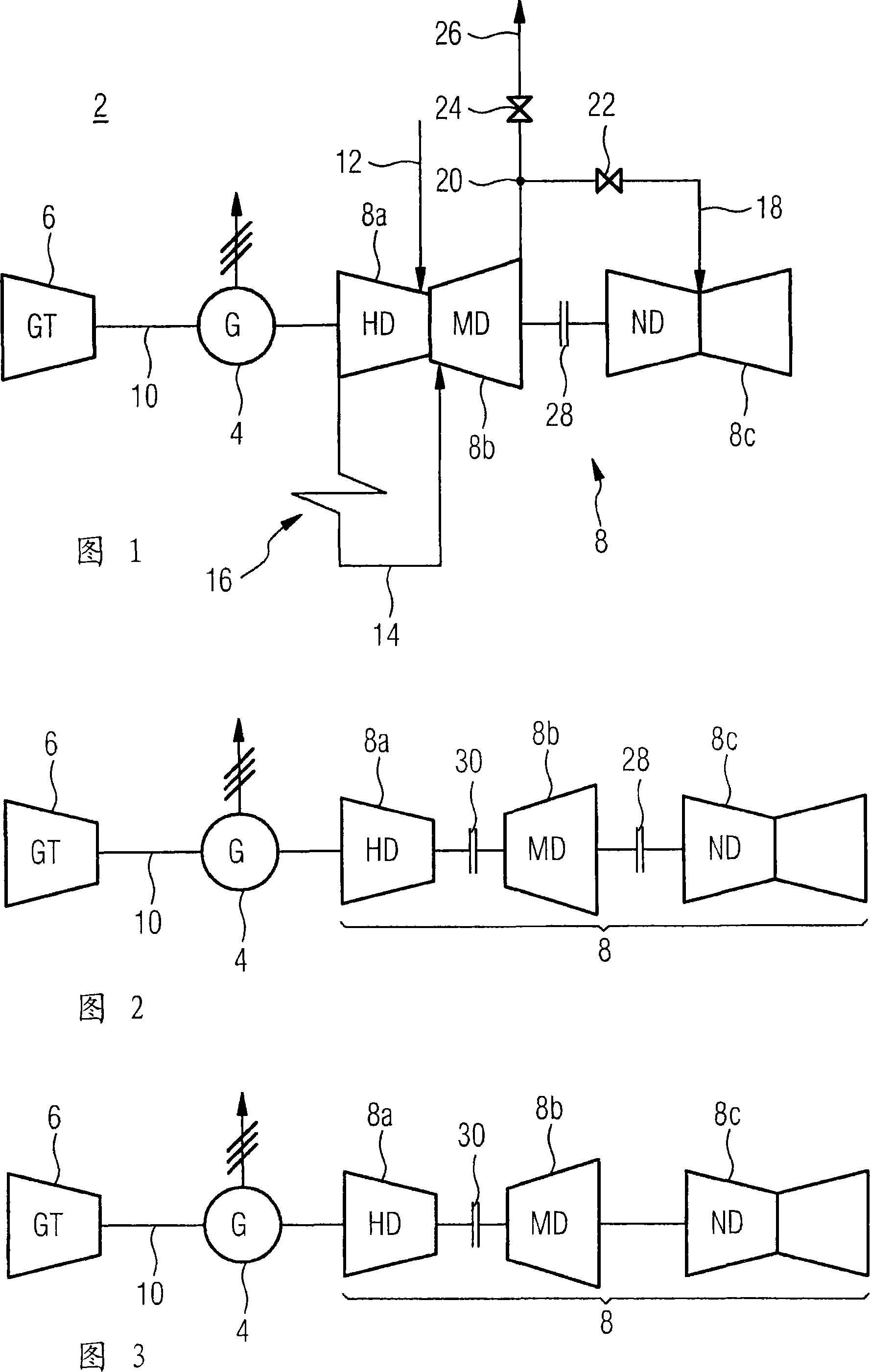

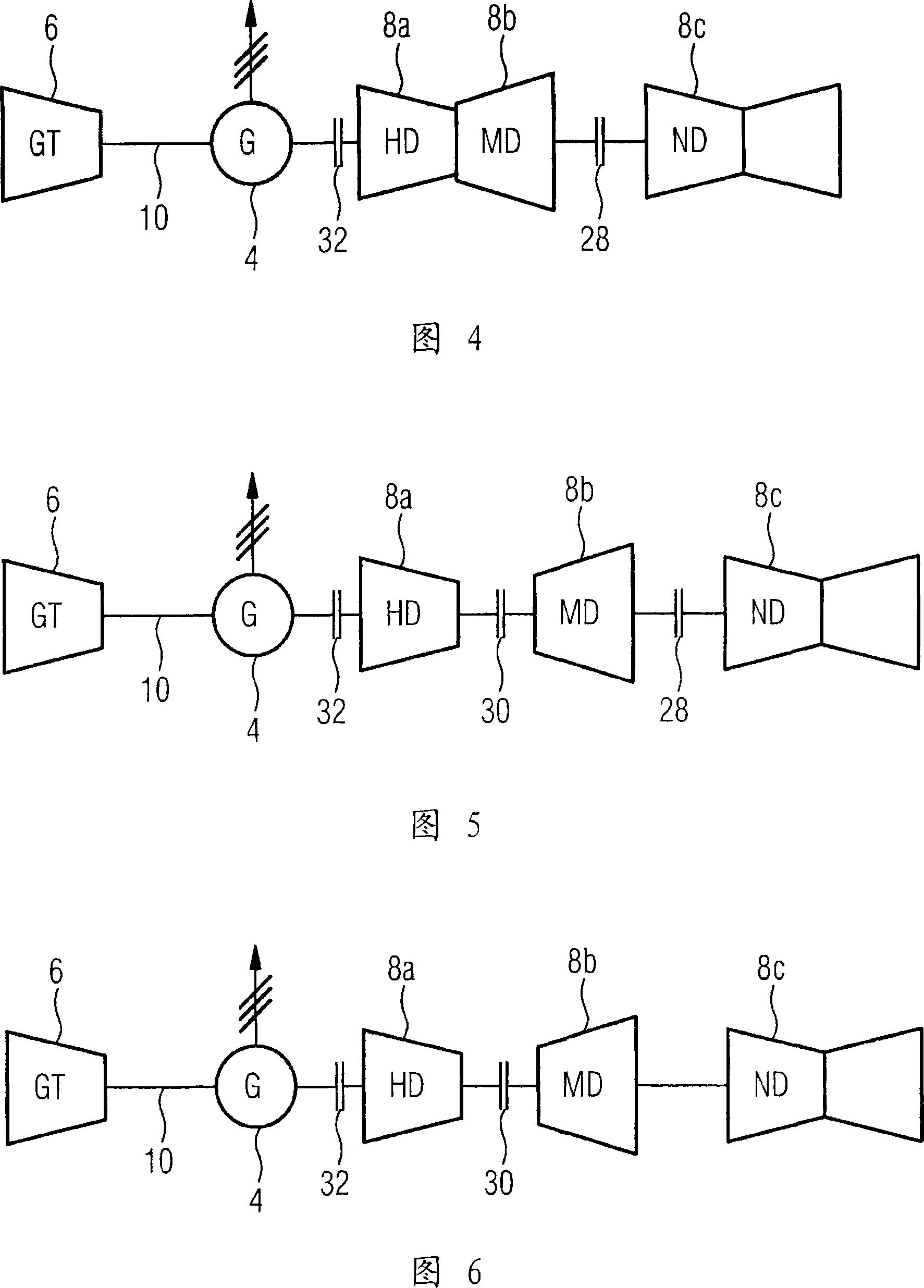

[0023] The gas and steam turbine plant 2 shown in Figure 1 is an integral part of the GuD power plant. In order to effectively utilize the primary energy of minerals, a thermally coupled GuD device is used. The gas and steam turbine plant 2 for this purpose has a generator 4, a gas turbine 6 and a steam turbine 8. The steam turbine 8 here includes a high-pressure stage 8a, an intermediate-pressure stage 8b, and a low-pressure stage 8c. Their respective pressure states during operation are also marked with the letters HD, MD or ND in Figure 1. The hot exhaust gas formed when a fossil fuel is burned in the gas turbine 6 is used to heat a waste steam boiler not shown in the figure, and steam for operating the steam turbine 8 is generated in the waste steam boiler through the vaporization of water. The gas turbine 6, the steam turbine 8, and the generator 4 are connected one after another on a shaft 10 oriented along a common axis in a so-called single-shaft arrangement structure. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com