Gas and steam turbine installation and method for operating the same

A technology for steam turbines and gas turbines, which is applied in gas turbine installations, steam engine installations, jet propulsion installations, etc., and can solve problems such as large space locations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

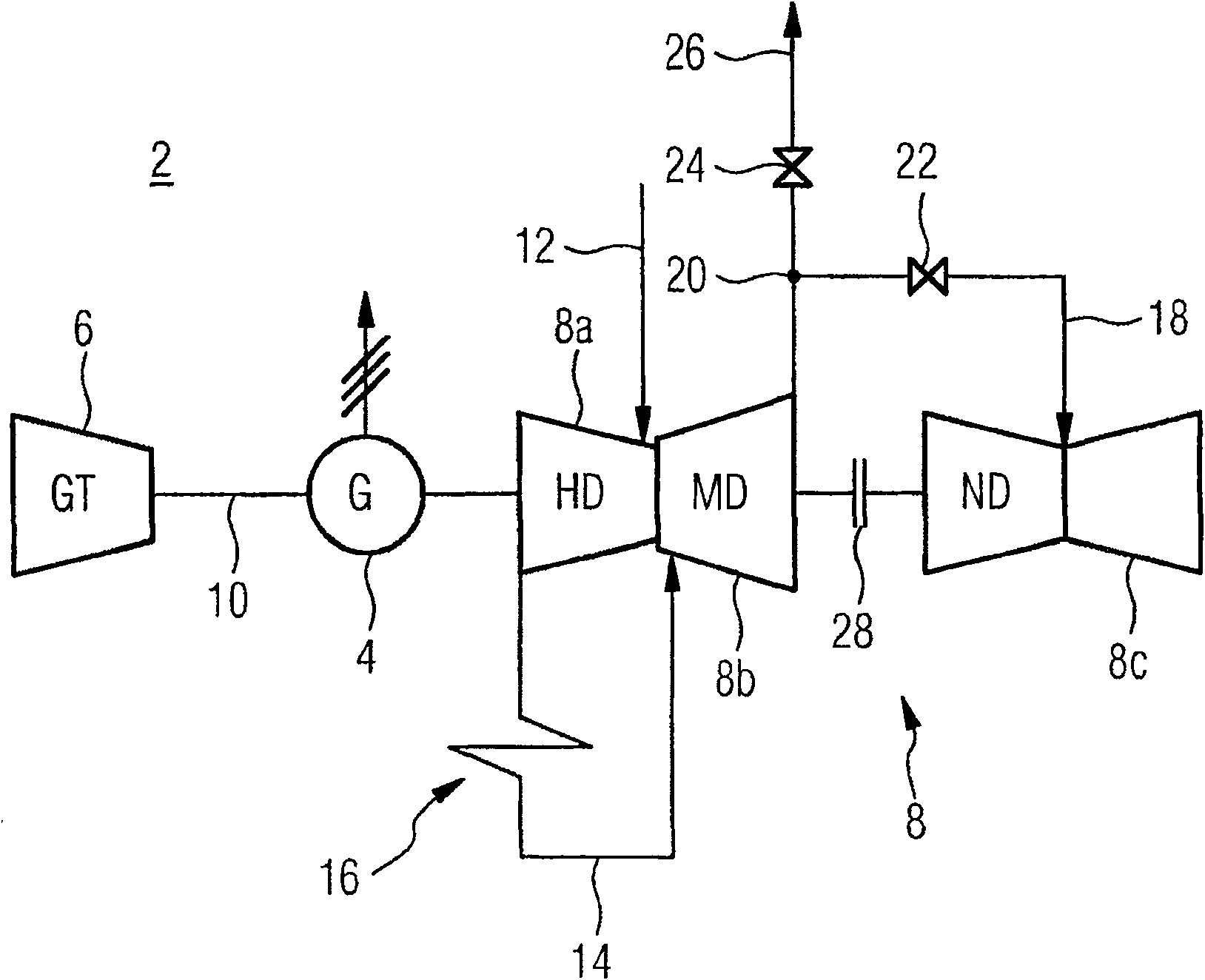

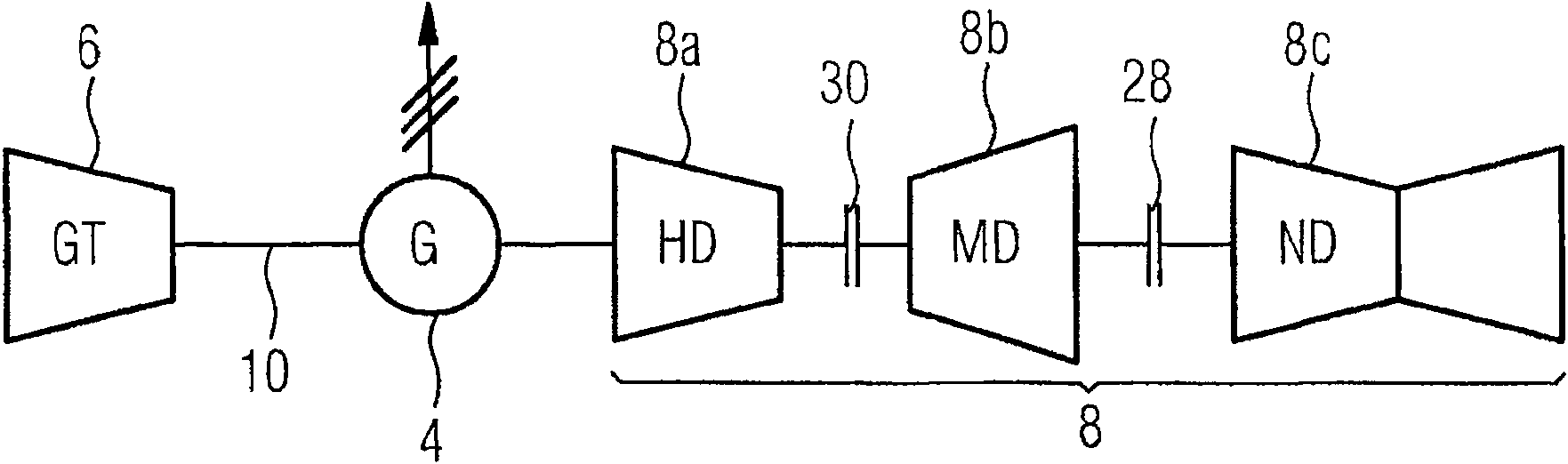

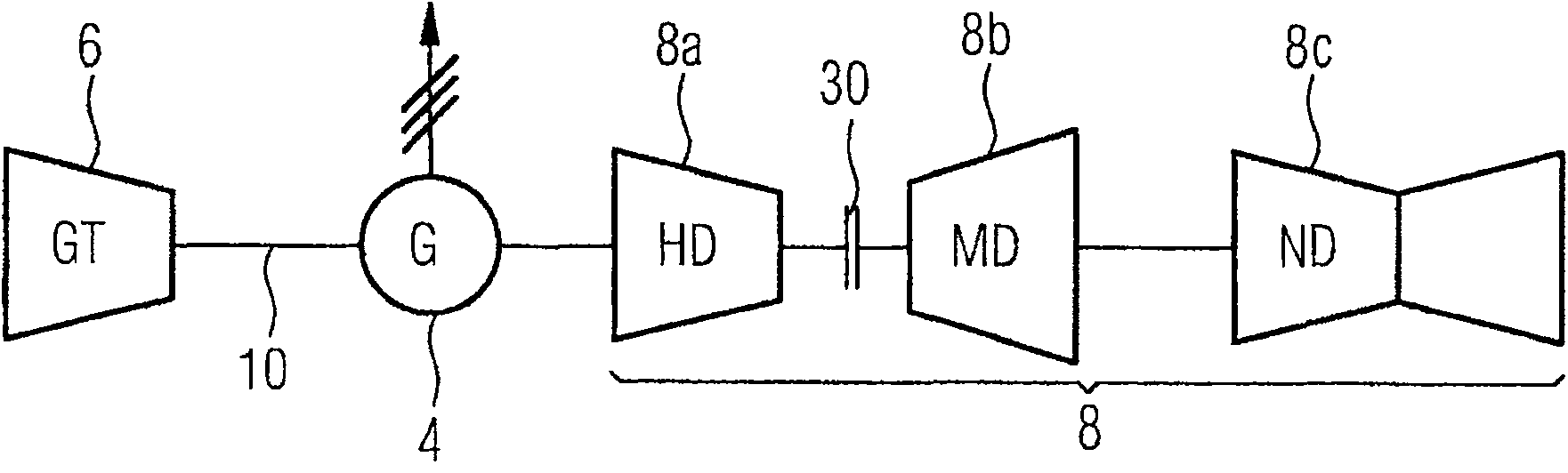

[0023] figure 1 The gas and steam turbine plant 2 shown is an integral part of the GuD power plant. In order to utilize the primary energy of the minerals particularly efficiently, a GuD unit is used which is coupled thermodynamically. For this purpose the gas and steam turbine plant 2 has a generator 4 , a gas turbine 6 and a steam turbine 8 . The steam turbine 8 here comprises a high-pressure stage 8a, a medium-pressure stage 8b and a low-pressure stage 8c. Their respective pressure states that exist during operation are in the figure 1 Also marked with the letters HD, MD or ND. The hot exhaust gas formed during the combustion of a fossil fuel in the gas turbine 6 is used to heat an exhaust steam boiler (not shown in the figure), in which steam is generated for operating the steam turbine 8 by evaporating water. The gas turbine 6, the steam turbine 8 and the generator 4 are successively connected on a shaft 10 oriented along a common axis according to a so-called singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com