Metal heat shield element with optimized cooling air function

A technology for cooling air and components, used in lighting and heating equipment, combustion methods, continuous combustion chambers, etc., can solve problems such as increased hot air, and achieve the effect of avoiding thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

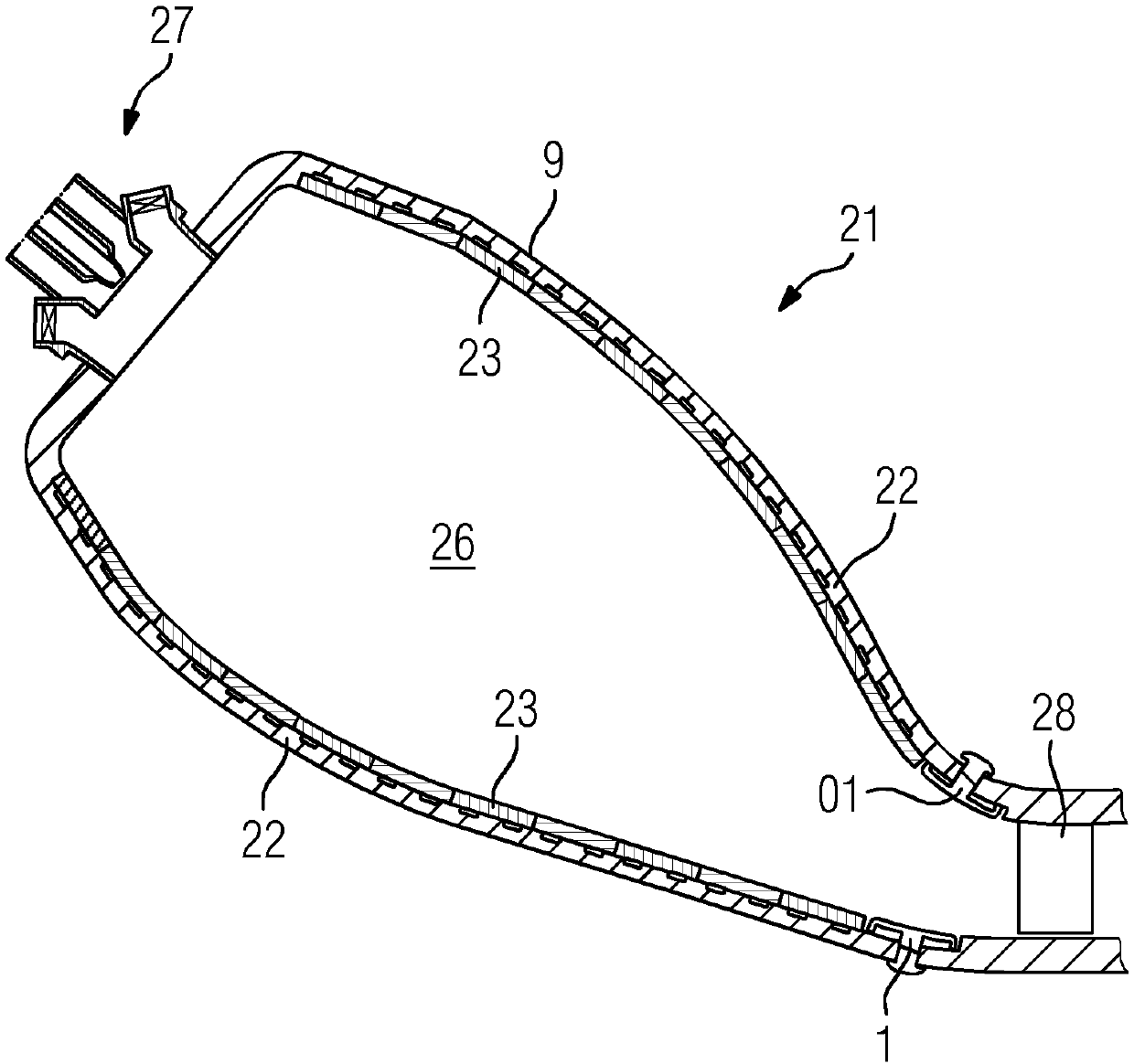

[0038] figure 1 A section through the combustion system of the combustion chamber 26 is shown schematically and by way of example. A burner 27 is arranged in the inlet in the upper region of the combustion chamber 26 . Mixing of fuel and compressed air takes place there. Combustion takes place in the combustion chamber 26 . Through an outlet at the downstream end 24 of the combustor 26 , hot combustion gases enter the turbine where the fuel gases contact a first stationary vane 28 . To prevent fouling, the combustion chamber 26 is lined with ceramic heat insulating tiles 23 and metal heat insulating elements 01 , which are fixed to the load-bearing structure 22 of the heat shield 21 .

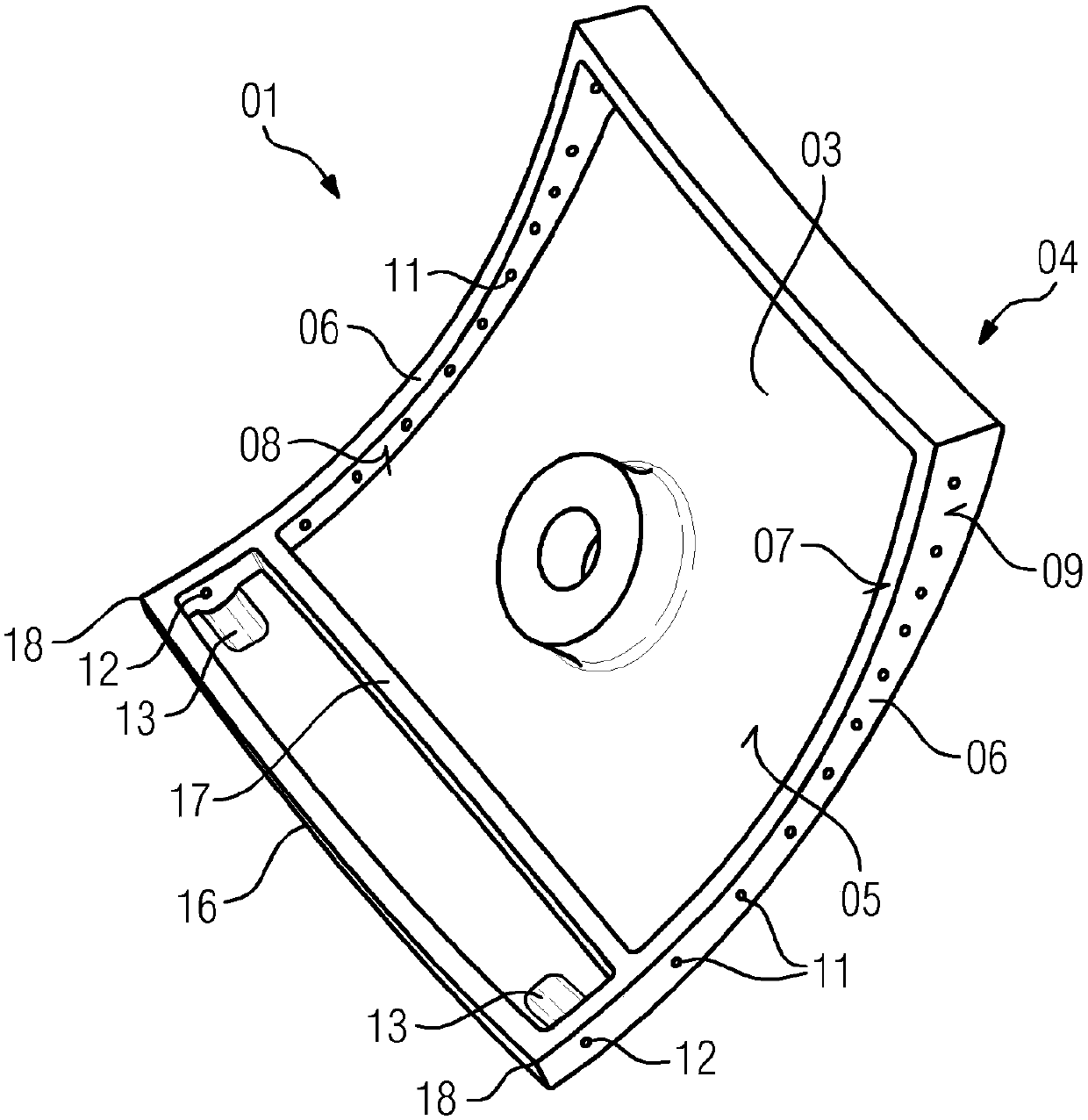

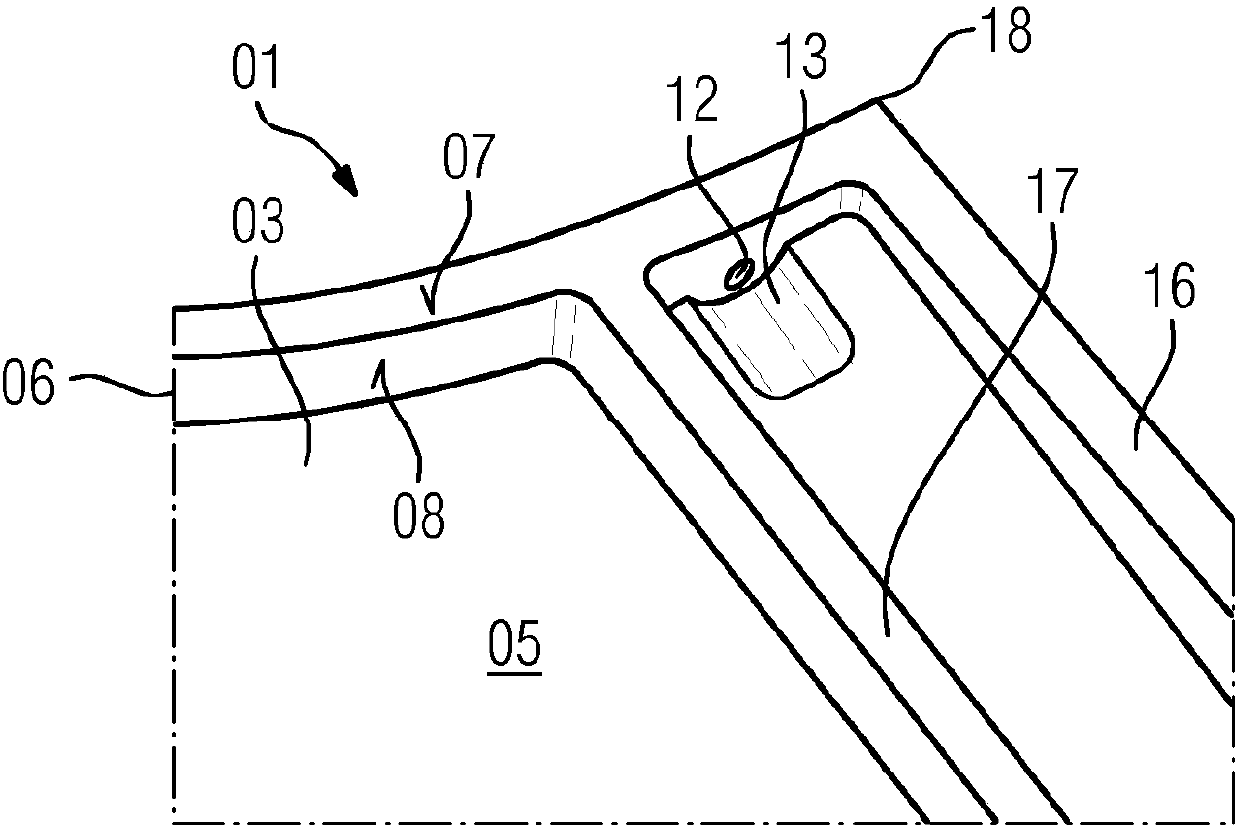

[0039] figure 2 A metal thermal insulation element 01 is shown schematically and by way of example in an embodiment according to the invention, which is used in a heat shield 21 for a combustion chamber 26 of a gas turbine. The thermal insulation element 01 comprises a wall 03 having a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com