Device for melt spinning and cooling a plurality of synthetic filaments

A technology of melt spinning and filament, which is applied in the direction of filament/thread forming, textile and paper making, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

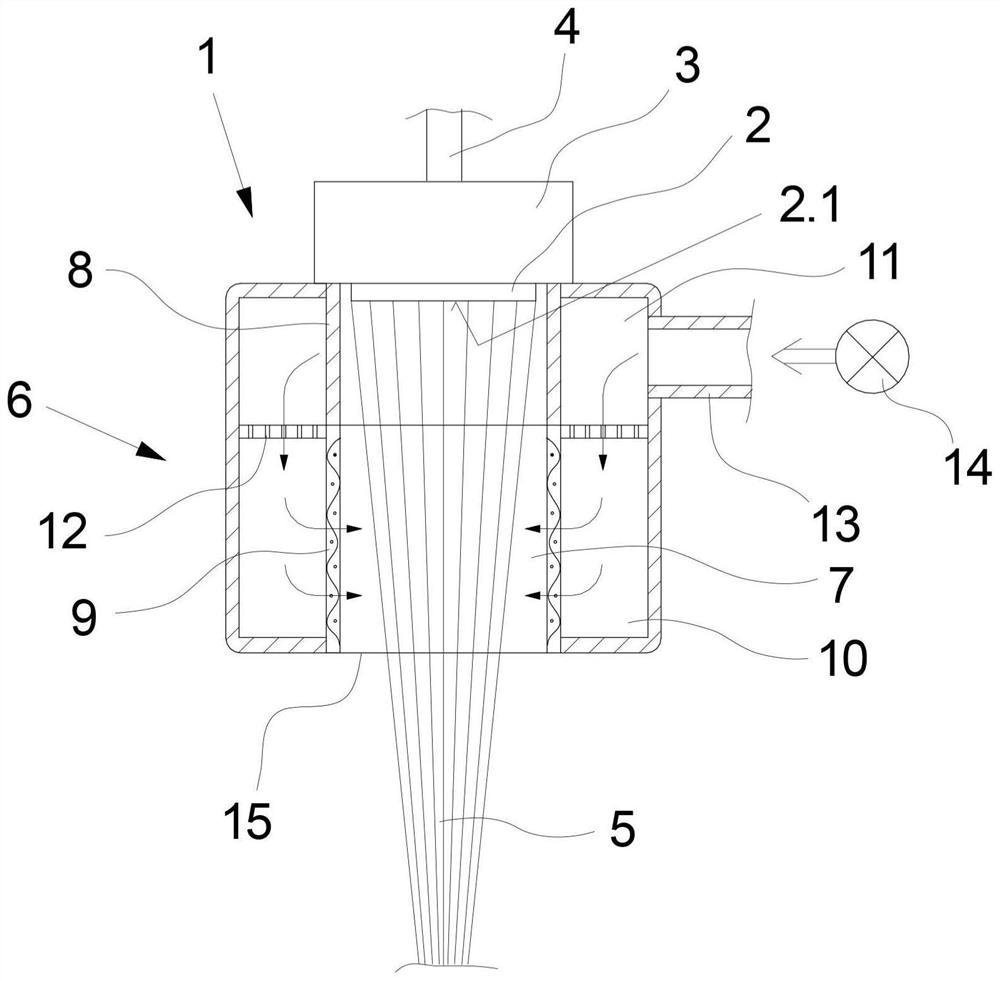

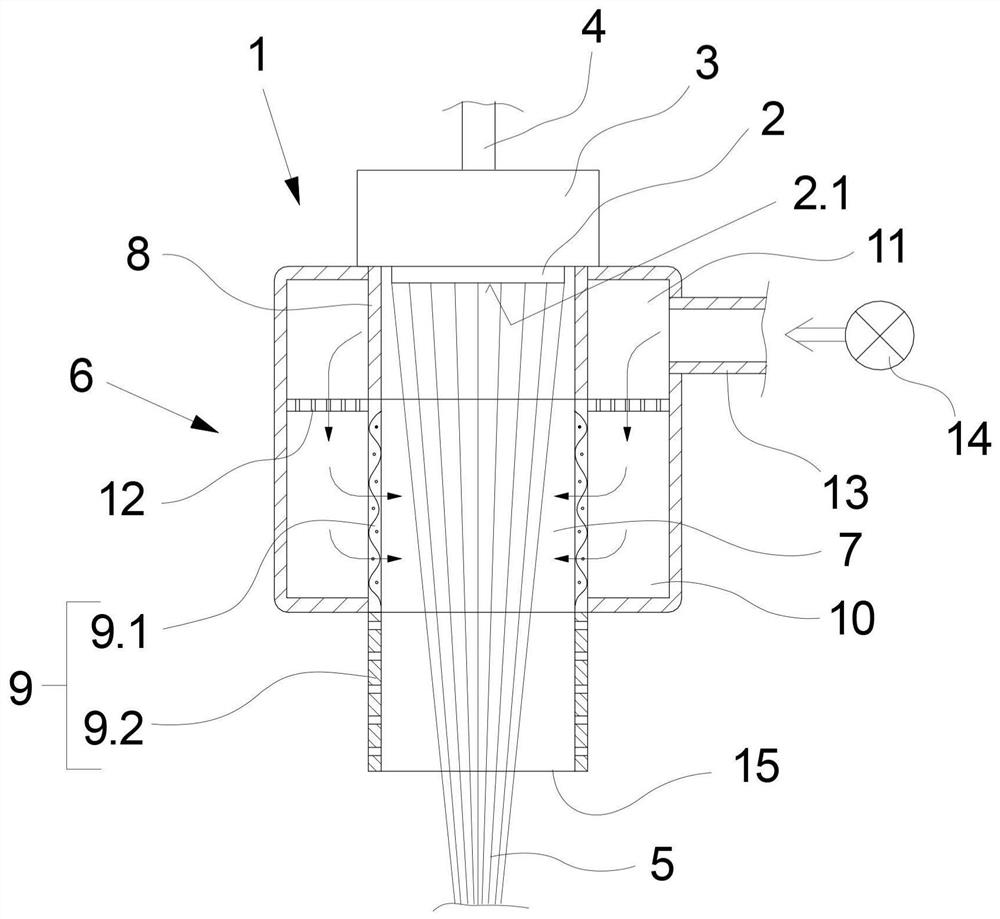

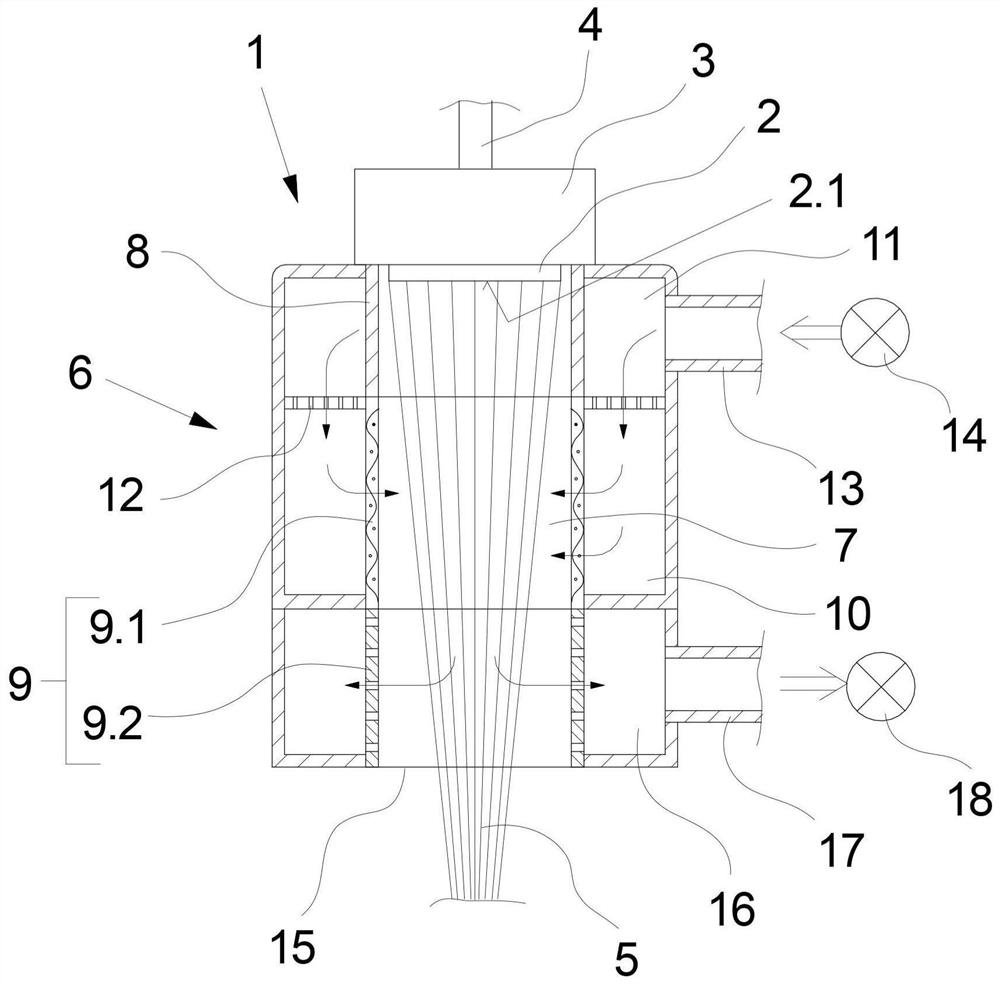

[0024] exist figure 1 , a first exemplary embodiment is schematically shown in cross-sectional view. The exemplary embodiment has a spinning device 1 and an underlying cooling device 6 . The spinning device 1 is shown here only schematically and has a spinning head 3 which has a spinneret 2 on its underside. The spinning head 3 is designed to be heated and has further components (not shown here) for guiding the melt, such as distribution lines and spinning pumps. The spinneret 2 has a plurality of nozzle openings 2.1 on its underside. The spinneret 2 is connected to the melt inlet 4 on the top side of the spinneret 3 so that during operation the polymer melt is extruded into thin filaments 5 through the nozzle openings 2.1 of the spinneret 2 . exist figure 1 The spinning device 1 is shown functionally in , in which a plurality of synthetic filaments 5 are produced.

[0025] The cooling device 6 arranged below the spinning device 1 has a hollow cylindrical cooling well 7 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com