Die for pre-forming inner holes of deep-hole shaft parts, method for forming inner holes and forming process of deep-hole shaft parts

A technology of preforming and forming parts, applied in the direction of metal extrusion dies, etc., can solve the problems of reducing product performance and material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

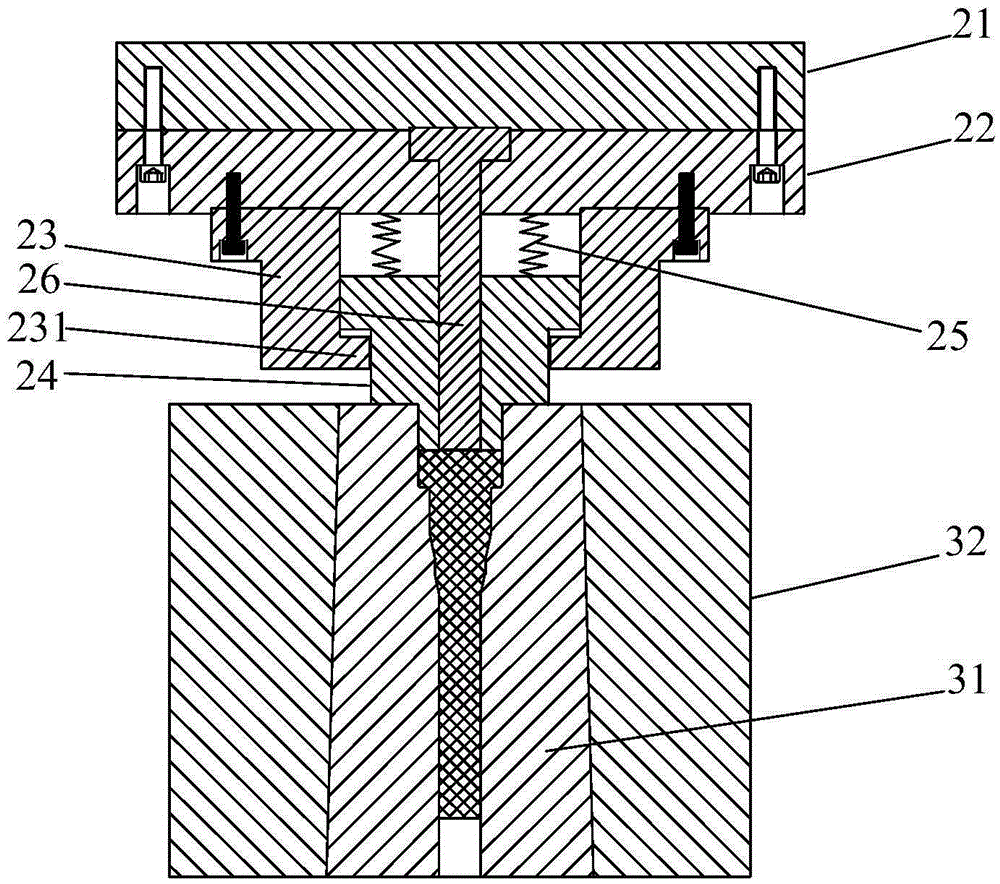

[0030] see below Figure 1 to Figure 10 The mold for preforming the inner hole of the deep-hole shaft part, the method for forming the inner hole and the forming process of the deep-hole shaft part according to the present invention are described in detail.

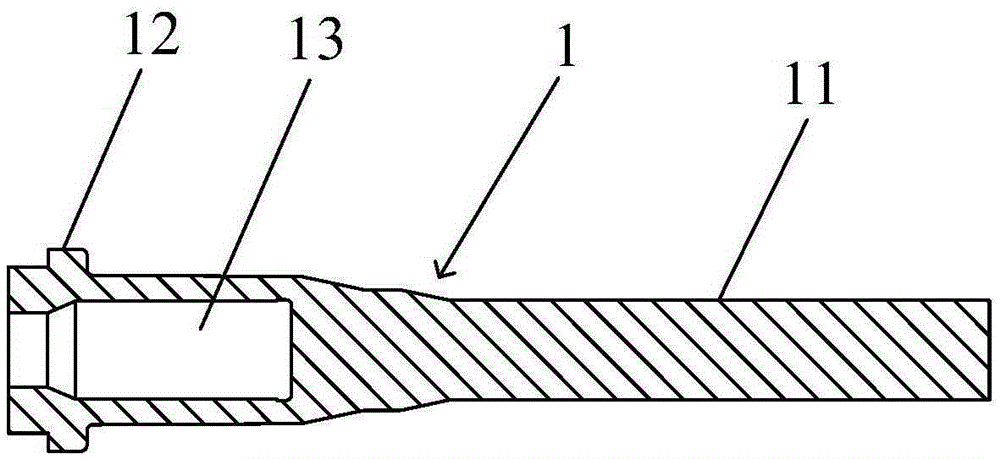

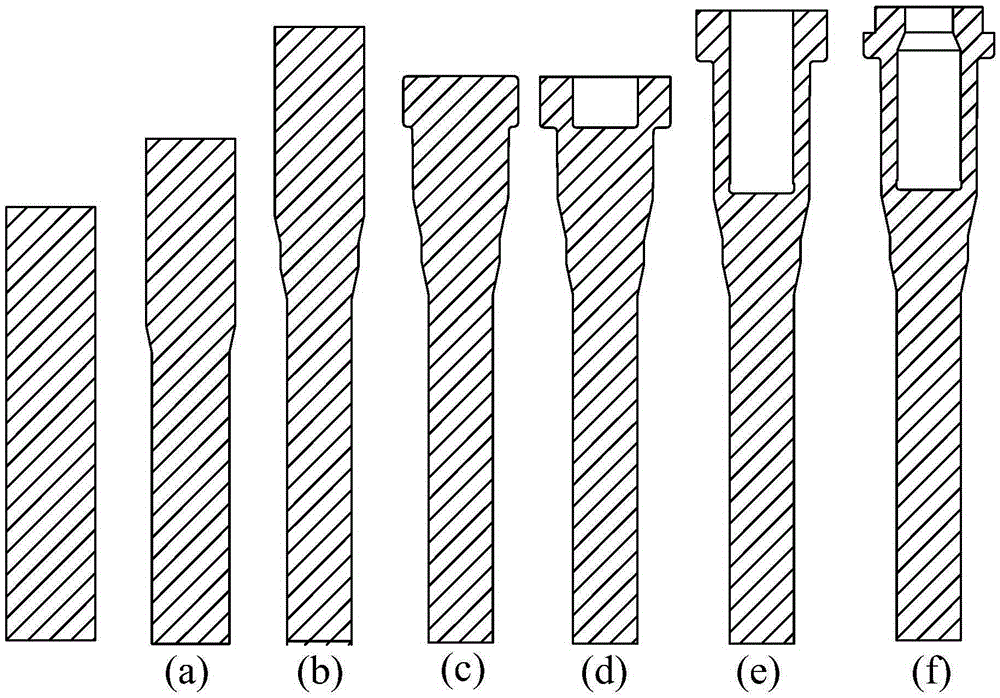

[0031] Such as figure 1 As shown, the deep hole shaft member 1 usually has an elongated stem 11, a flange 12 is provided at the head of the stem 11, a blind hole 13 is arranged inside the head of the stem 11, and the blind hole 13 The upper part is closed. In the present invention, the deep hole shaft part 1 mainly adopts figure 2 The process flow shown to form, refer to figure 2 As shown, the forming process of deep hole shaft parts mainly includes the following steps:

[0032] Step 1: Carry out a reducing extrusion process on the forming rod part of the deep hole shaft to form figure 2 Formed parts as shown in (a);

[0033] step 2, yes figure 2 The formed part shown in (a) is subjected to secondary diameter r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com