Turning machine and control method of a stamping control device

A control method and a technology of a control device, which are applied in the field of stamping equipment, can solve the problems of reducing the degree of freedom of the transfer manipulator, the high cost of the transfer manipulator, and the difficulty in adjusting the flipped workpiece, so as to reduce the degree of freedom and cost, realize automatic control, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

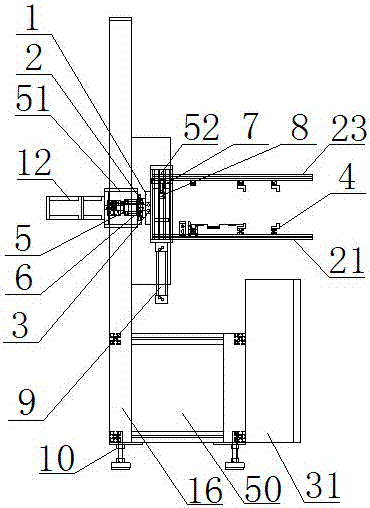

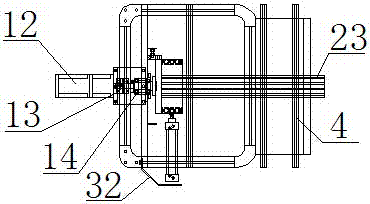

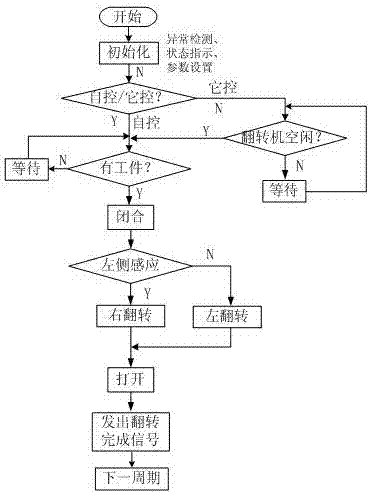

[0021] Such as figure 1 is the front view of the present invention, figure 2 is a side view of the present invention, image 3 It is a top view of the present invention, a turning machine of a stamping control device, including a base 50, a bracket 16, a rotating mechanism 51, a clamping mechanism 52 and an electric control box 31. The bracket 16 is installed on the inner side of the base 50, and the electric control box 31 is installed on the On the outside of the base 50, the rotating mechanism 51 is fixed on the support 16 through the connecting plate 25, and the clamping mechanism 52 is connected with the rotating mechanism 51 through the rotating plate 1. The rotating mechanism 51 includes a stepper motor 12, a shaft coupling 13, a positioning sleeve 5, Bearing seat 6, bearing 14 and rotating shaft 2, clamping mechanism 52 includes cylinder 9, floating joint 8, floating joint mounting plate 7, upper connecting plate 17, guide post 18, fixed beam 21, lower connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com