Shaking press clamping groove type combined mould

A combined mold and slot-type technology, which is applied in the direction of manufacturing tools and ceramic molding machines, can solve the problems of easy loosening and deformation of welding parts, and achieve the effect of reducing production costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the specific embodiments.

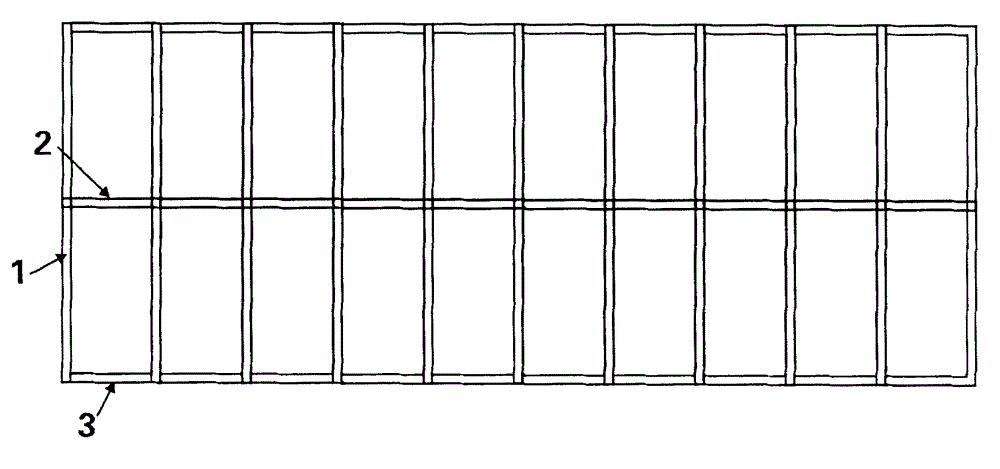

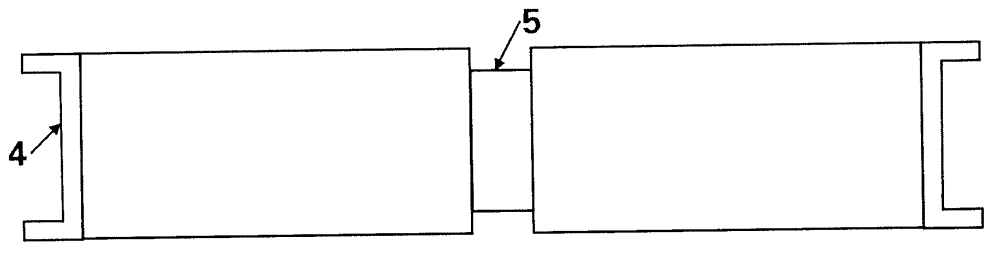

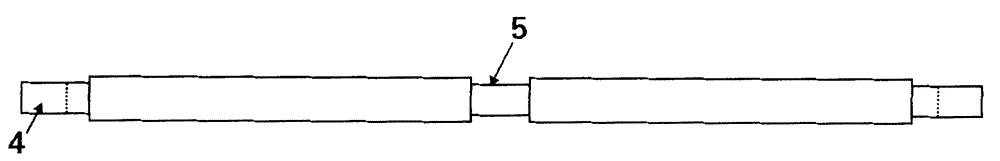

[0012] The vibration-pressure slot-type composite mold is composed of multiple A-plates, B-plates and C-plates.

[0013] The working process of the vibration-pressing slot-type combination mold of the present invention is as follows:

[0014] The vibration-pressure slot-type combination mold is composed of multiple A-plates ( figure 2 ), Board B ( Figure 4 ) and C-plate ( Image 6 )combination( figure 1 ①, ②, ③). The A board is a longitudinal lining board with bayonet slots at both ends and a slot in the middle; the B board is a middle horizontal lining board with bayonet slots at both ends; the C board is a horizontal lining board at both ends with The interface is curved inwards in an arc ( Figure 7 ). When combined, board B ( Figure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap