Mixer capable of fully stirring concrete

A mixer and concrete technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of insufficient mixing, unsatisfactory mixing effect, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

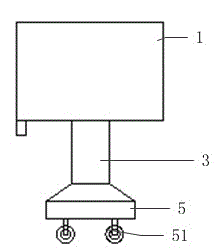

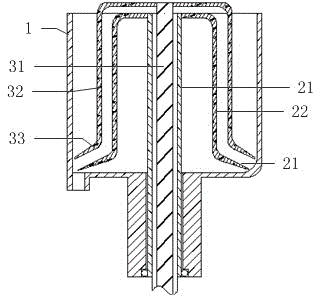

[0016] Such as figure 1 , figure 2 As shown, a mixer capable of fully mixing concrete in the present invention is composed of a mixing cylinder 1 and a rotating set 2 , and the rotating set 2 includes a rotating shaft 21 , a swing arm 22 and a shovel head 23 . The mixer also includes a reversing set 3 , including a reversing shaft 31 , a reversing arm 32 and a reversing shovel head 33 . The reverse rotation shaft 31 is arranged in the rotation shaft 21, coincides with the axis of rotation of the rotation shaft 21, and has a diameter smaller than that of the rotation shaft 21. One side is connected to the base 3 through a bearing and is connected to the motor of the driving device, and correspondingly, the rotating shaft 21 is connected to the motor through a gear set.

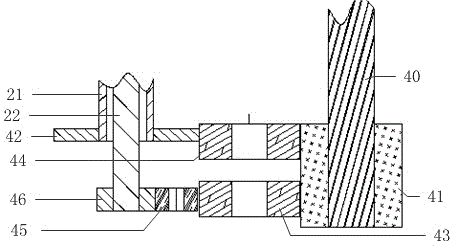

[0017] Such as image 3 As shown, the output gear 41 of the motor 4 is symmetrically distributed with the first gear 42 and the second gear 43 up and down, and the first gear 42 meshes with the third gear 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com