Double-stage driving type building cement stirring station

A driving type, construction technology, applied in mixing plant, clay preparation equipment, mixing operation control, etc., can solve the problems of cement mixing, waste, insufficient power, etc., to improve mixing efficiency, reduce production costs, and ensure construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

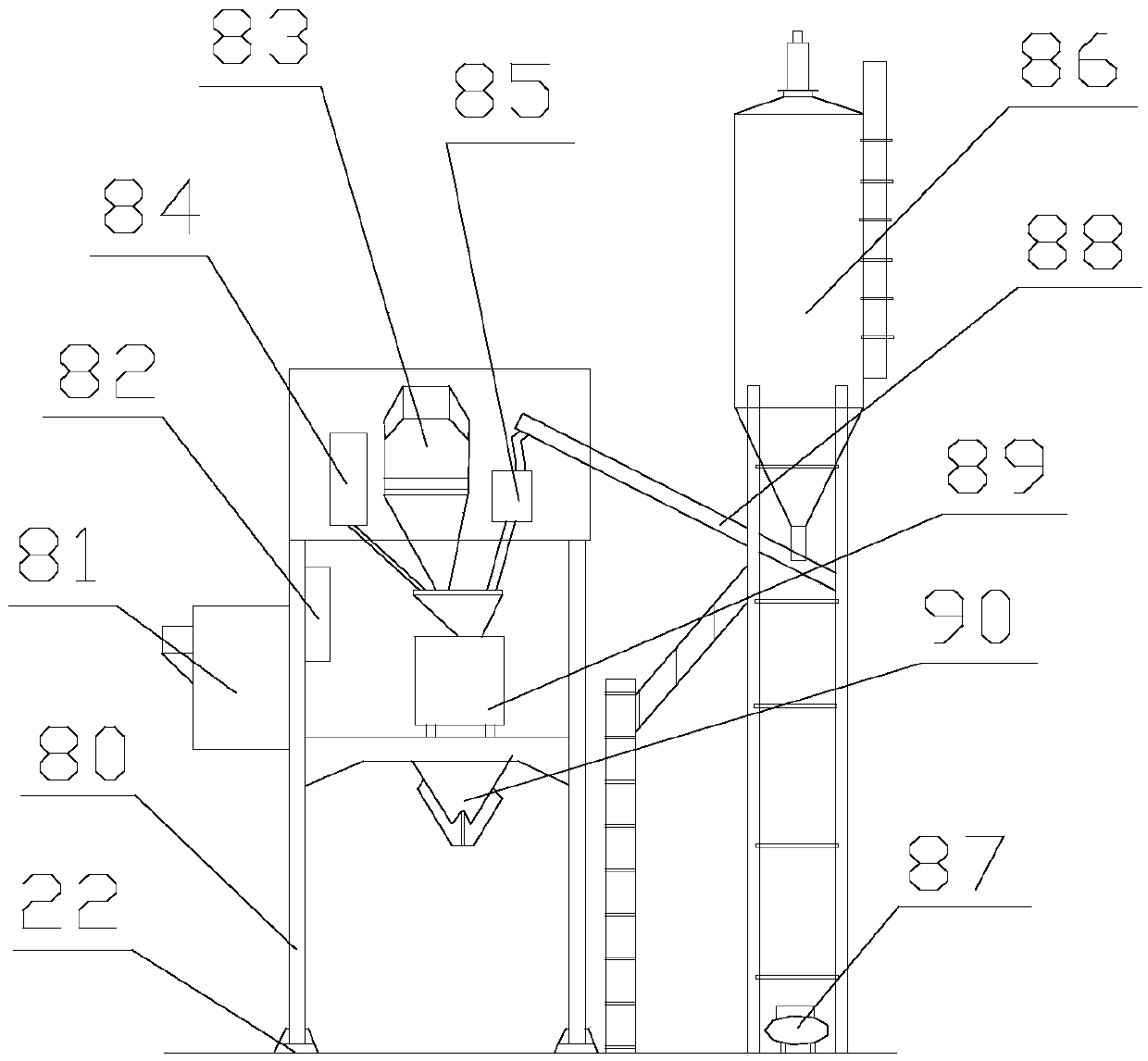

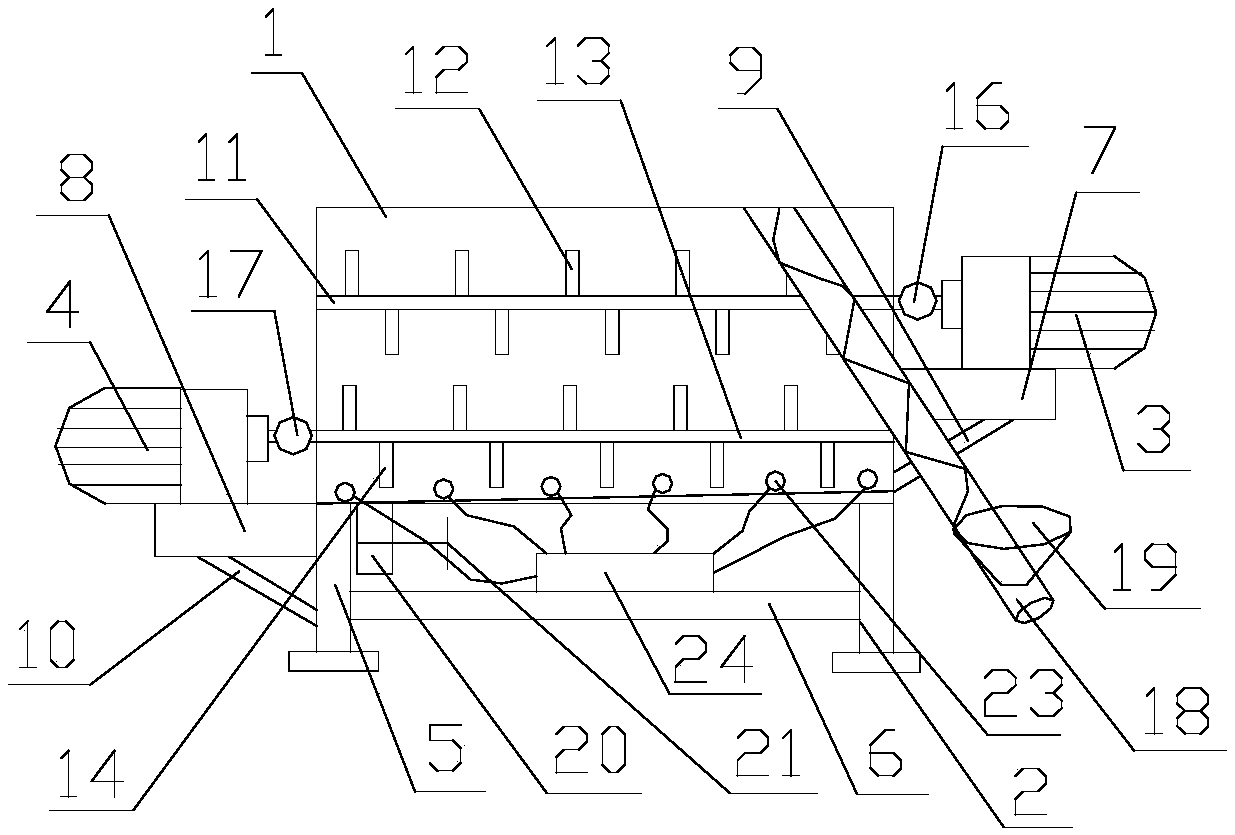

[0031] Such as Figure 1-4 As shown, the two-stage drive type cement mixing plant for construction provided by the present invention has the characteristics of high mixing efficiency, more uniform mixing, guaranteed construction progress, and effective protection of PLC controller power supply batteries to prolong its service life. The present invention includes a frame body 80, a feeding machine, water, and an admixture system. An operation room 81 is arranged on one side of the frame body 80, and a PLC controller 82 is arranged behind the operation room 81. The upper part of the frame body 80 is provided with Batching machine 83, one side of the batching machine 83 is provided with a gravel storage hopper 84, the other side of the batching machine 83 is provided with a cement weighing hopper 85, and the side of the frame body 80 close to the cement weighing hopper 85 is provided with a cement bin 86, an air system 87 is provided below the cement silo 86, and the cement silo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com