Conveying device for magnetic ring

A technology of magnetic rings and driving devices, which is applied in the direction of coating, etc., can solve the problems of increased labor costs, low work efficiency, and low stability, and achieve the effects of reducing labor intensity, improving production efficiency, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

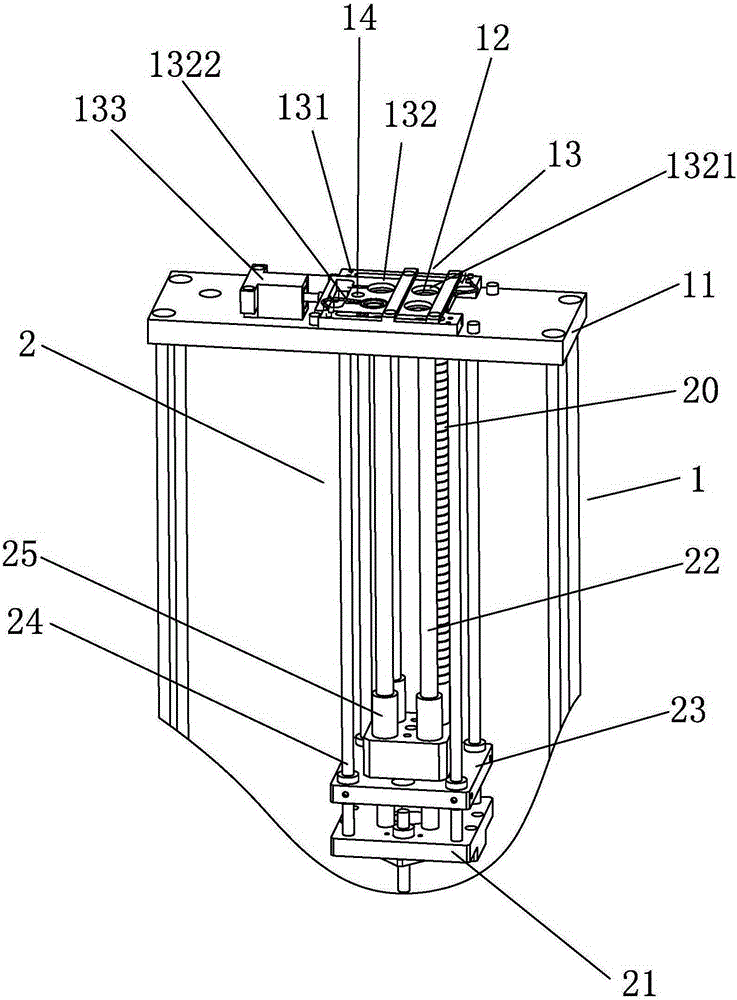

[0016] refer to figure 1 , a magnetic ring feeding device, comprising a material retrieving support 1 and a material rack 2 for placing a magnetic ring 20, the retrieving support 1 includes a retrieving positioning plate 11 positioned above the material rack 2 and a retrieving positioning plate 11 mounted on the retrieving positioning plate 11 The dislocation mechanism 13 on the top, the dislocation mechanism 13 includes a guide rail 131 and a dislocation plate 132 that can translate along the guide rail 131 on the reclaiming positioning plate 11, and one end of the dislocation plate 132 is connected with a 13 translational driving device 133, the material rack 2 includes a lower plate 21 that can move up and down, and the lower plate 21 is vertically installed with a discharge column 22 for placing the magnetic ring 20 upwards. The number of discharge columns 22 in the present invention is four The retrieving positioning plate 11 is provided with a through hole 12 at a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com