Cob crushing and grinding type garbage disposal machine and disposal method thereof

A garbage disposal and corn cob technology, which is applied in grain processing, cocoa, food science, etc., can solve the problems of high vibration and noise of processors, large garbage particles, and inability to take them out, achieving good results, reasonable garbage disposal, and finely crushed garbage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

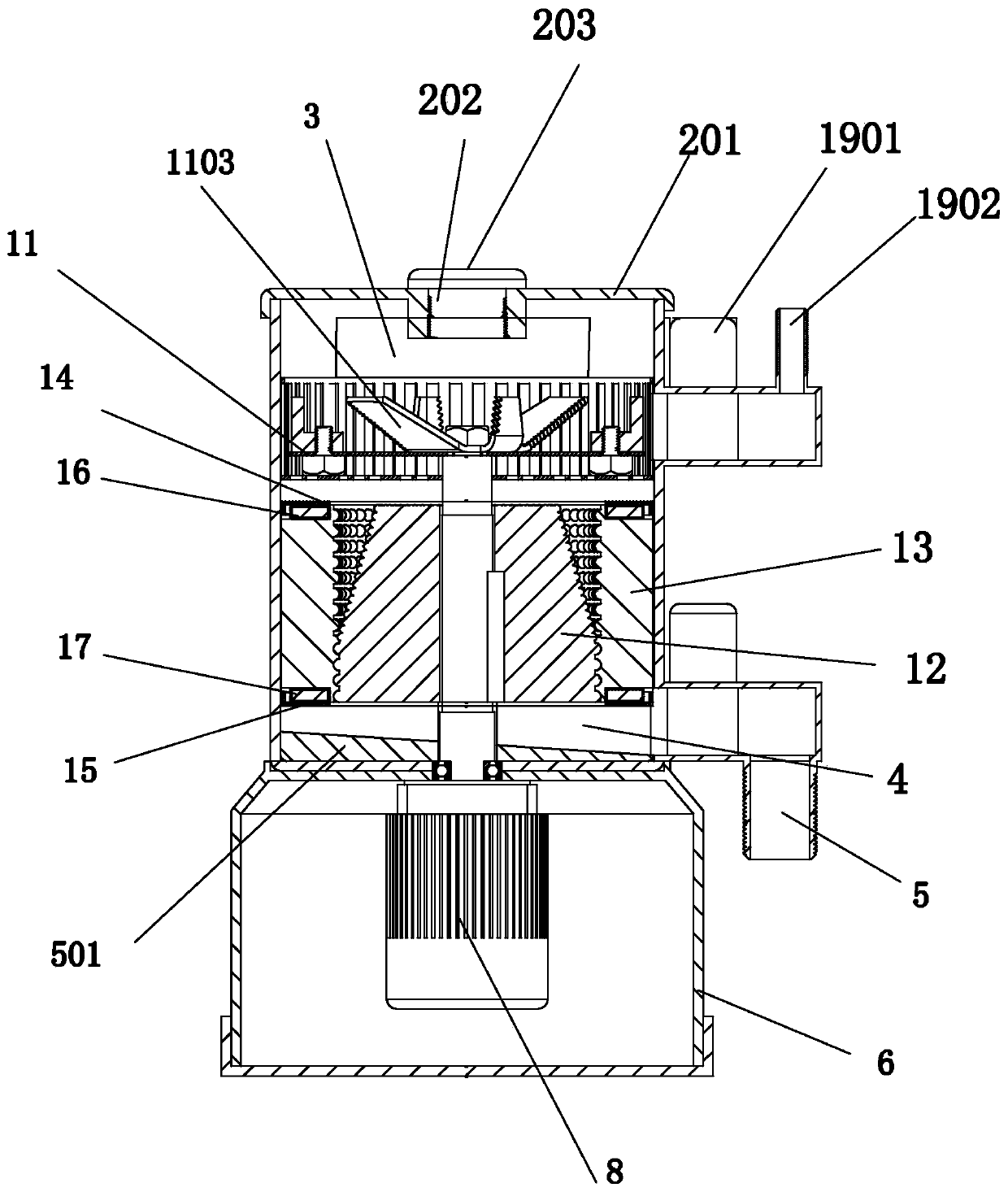

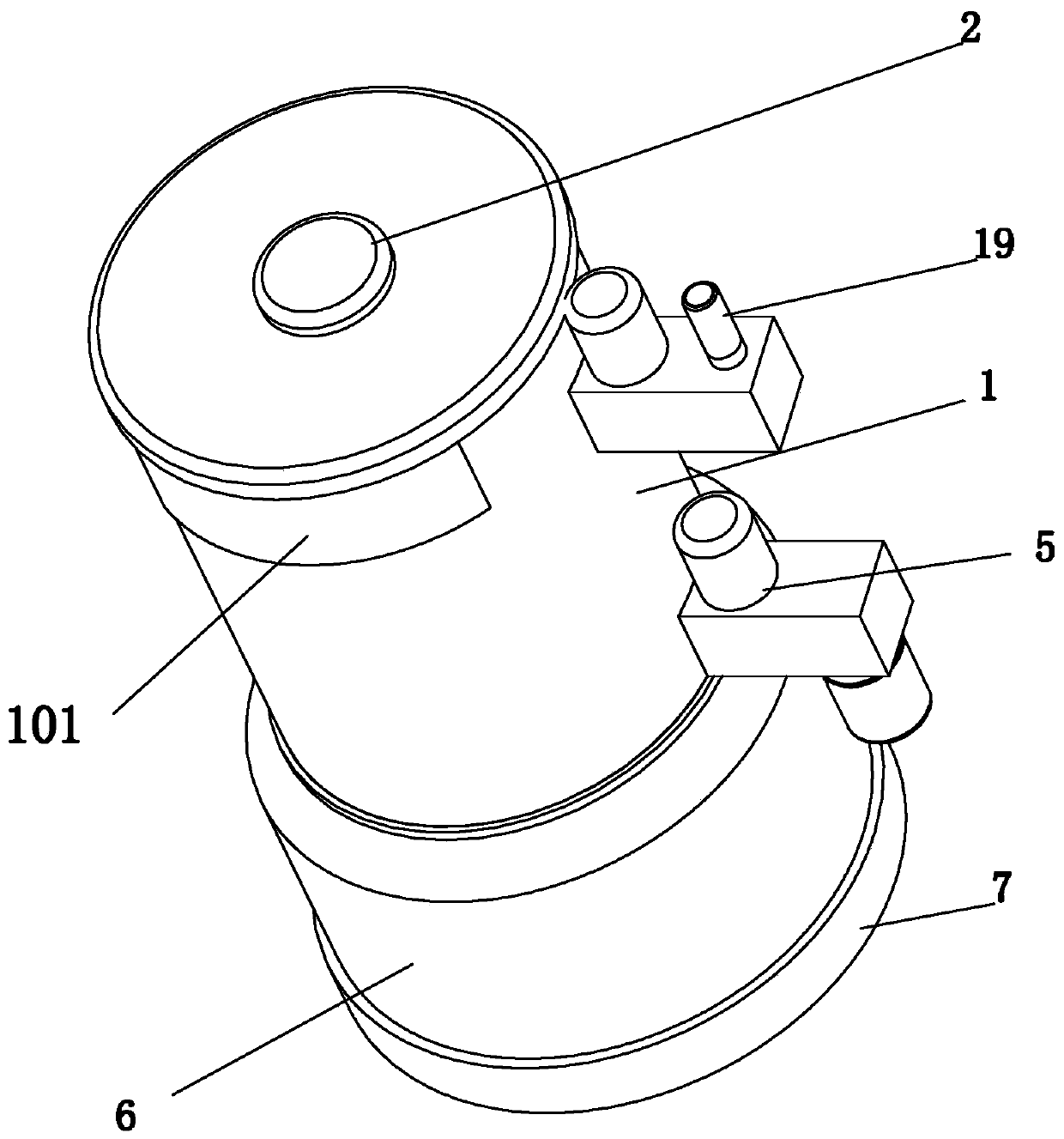

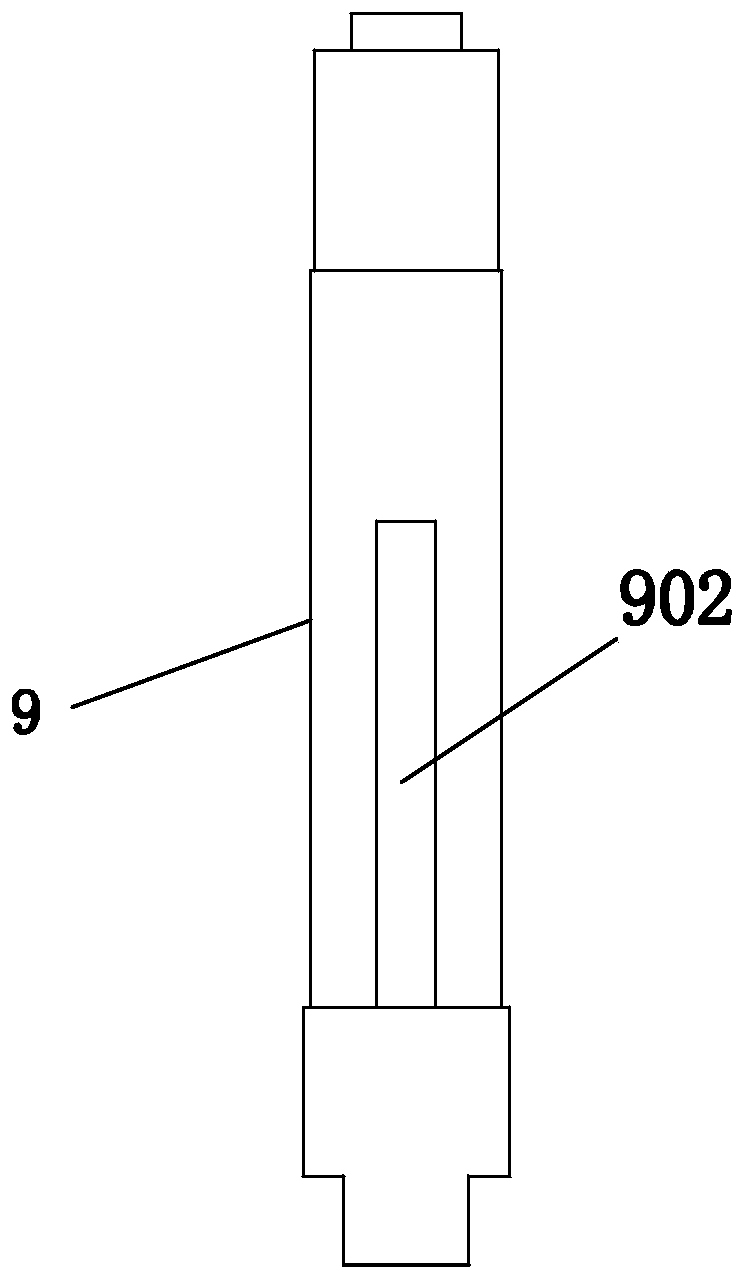

[0070] Such as Figure 1 to Figure 11-2 As shown, the corn cob rolling and grinding type garbage disposer, referred to as garbage disposer, such as figure 1 , figure 2 As shown, it includes a barrel 1 part and a power mechanism. The barrel 1 part includes a barrel 1, a feeding mechanism 2, a feeding storage area 3 at the upper part of the barrel 1, a discharge storage area 4 at the lower part of the barrel 1, and Discharge mechanism 5; The discharge mechanism 5 is arranged below and on one side of the discharge storage area 4, and the power mechanism is arranged below the cylinder 1; Figure 3-1 to Figure 4 As shown, the power mechanism includes a base 6, a base 7, a motor 8, a motor shaft sleeve 9, and a 6003 type sealed bearing 10. The 6003 type sealed bearing 10 is a 6003-2rs type sealed bearing; the base 6 is mounted on the base 7, the motor 8 is installed in the upper part of the base 6, the motor shaft sleeve 9 extends upward into the cylinder 1, the upper end of the motor...

Embodiment 2

[0093] The garbage disposer can also be combined with the sewer of a pool (not shown in the figure) to process garbage. At this time, first remove the sealing plug 203, and connect the feed hole 202 of the upper cover 201 of the garbage disposer to the pool, and the slurry interface 503 is connected to the sewer. (Not shown in the figure) take over the connection, and at the same time the water inlet pipe joint 1902 is connected with the tap water pipe; the pool plus the upper space of the cylinder 1 becomes the feed storage area 3 of the garbage disposer, and the kitchen waste is directly stored in the pool and connected After the slurry interface 503 is connected to the sewer channel, the water inlet solenoid valve 1901 and the slurry solenoid valve 502 can be opened at the same time, and the crushed kitchen waste can be directly discharged to the sewer, thus realizing timing and automatic control of garbage disposal.

[0094] The same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com