Multi-spray-head 3D printer and cooperative printing method thereof

A 3D printer and multi-nozzle technology, applied in additive processing and other directions, can solve the problems of printing speed and printing accuracy, cannot really improve work efficiency, change the internal structure of printed parts, etc., to improve 3D printing efficiency and facilitate partition collaboration. Printing, avoiding the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

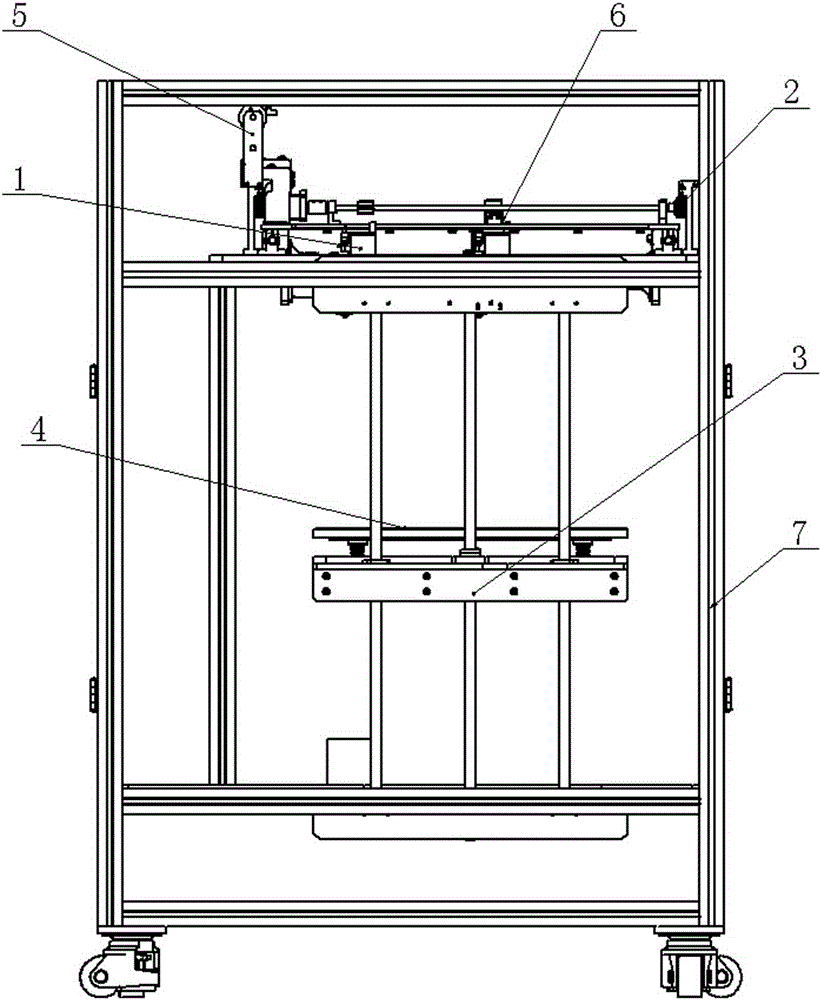

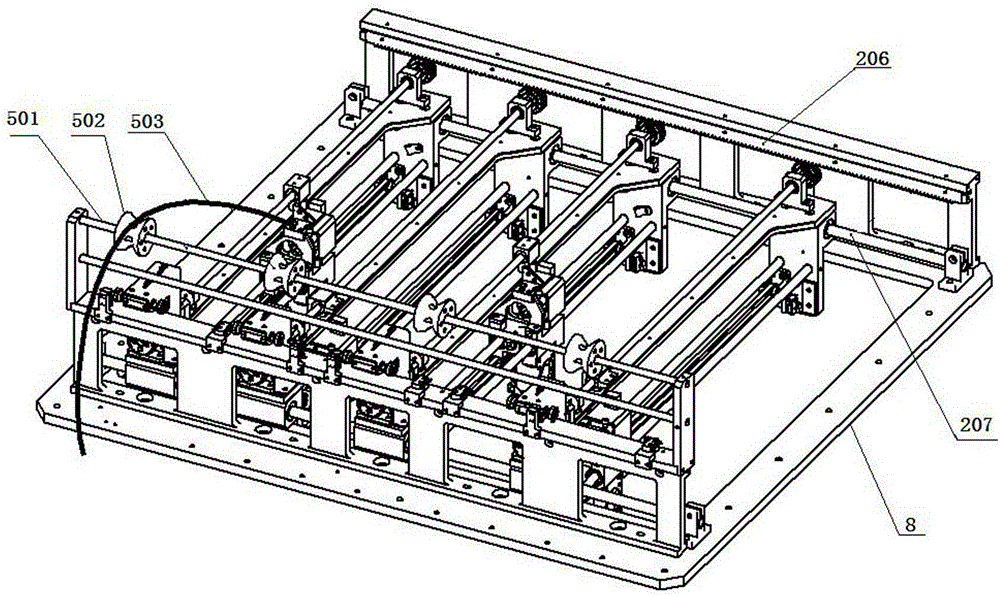

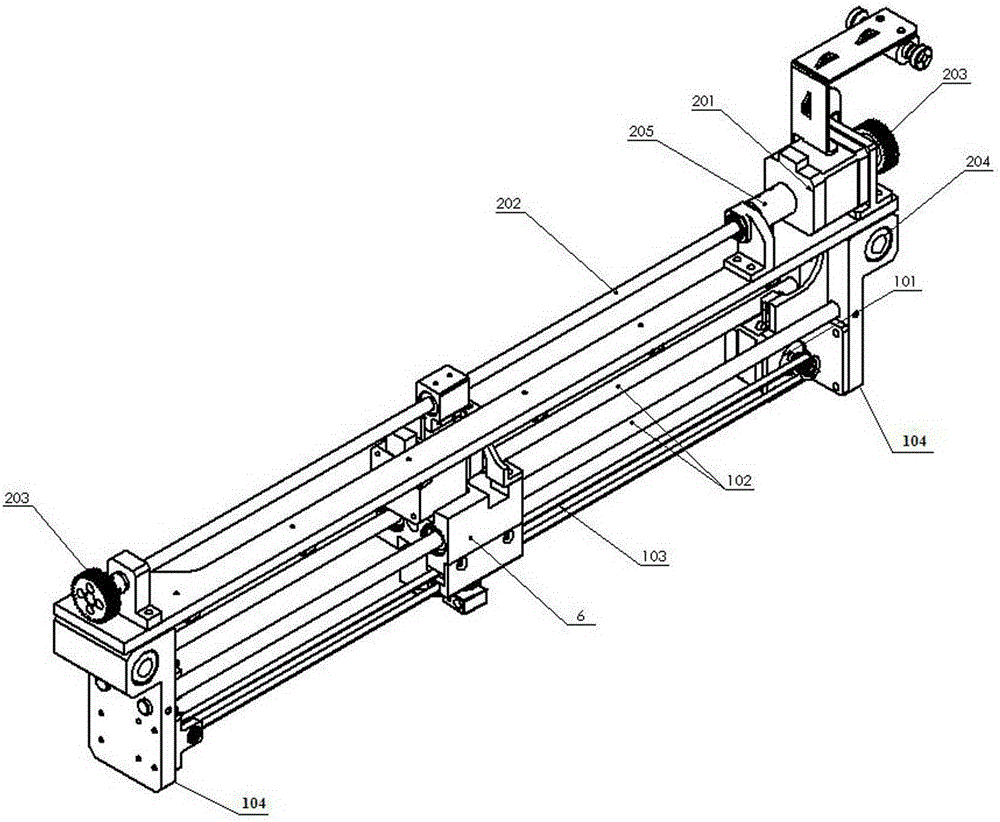

[0028] A 3D printer with multi-spray nozzles working cooperatively in partitions, including a motion mechanism and a control unit. see Figure 1-Figure 5 , the motion mechanism includes a body 7, an XY motion assembly, a Z-axis motion mechanism 3, and a printing platform 4. The XY motion assembly is provided with N X-axis motion mechanisms 1, N Y-axis motion mechanisms 2, and N delivery A wire mechanism 5 and N nozzles 6; said N≥1, and N is an integer. The N X-axis motion mechanisms 1 move independently of each other, and each X-axis motion mechanism 1 corresponds to a nozzle 6; the N Y-axis motion mechanisms 2 move independently of each other; the Z-axis motion mechanism 3 has only one, unified Adjust the height of all nozzles 6 relative to the printing platform 4; the N wire feeding mechanisms 5 work independently of each other, and each wire feeding mechanism 5 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com