Rear-mounted control handle for piling car

A technology for operating handles and stacking trucks, applied in the direction of lifting devices, etc., to achieve the effect of improving braking safety performance, intelligent performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing is described further.

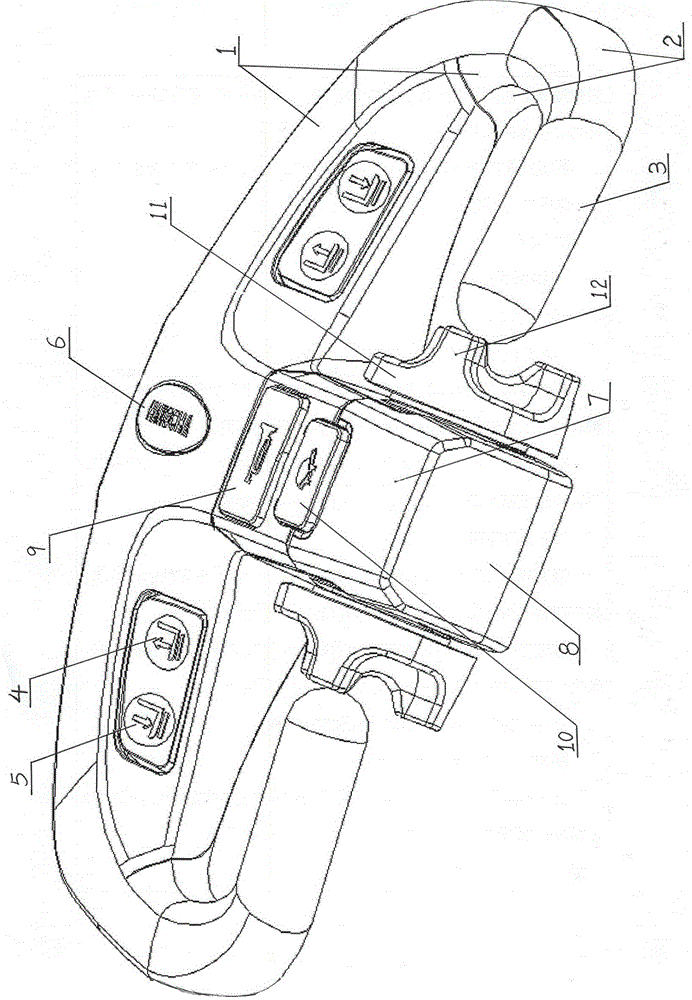

[0019] figure 1 As shown: a stacker truck rear joystick includes an upper cover 1, a lower housing 2 and a controller, the upper cover 1 encapsulates the controller in the lower housing 2, and the rear sides of the lower housing 2 are bent inwards into two The opposite handrail 3, a console 7 protrudes backward in the middle of the rear part of the lower housing 2, one side of the upper cover 1 is provided with rising and falling buttons 4, 5 or both sides are correspondingly provided with linked rising and falling buttons , the rear side of the console 7 is provided with an emergency reverse button 8, the upper end of the console 7 is provided with a horn button 9 and a turtle climbing button 10, and the console 7 is provided with a linkage on both sides of the corresponding two armrests 3. The forward and backward knob 11 is provided with a plurality of pushing bosses 12 facing the handrail, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com