A method for preparing metal by continuous reduction in molten salt medium

A molten salt medium and metal technology, applied in the field of metal material preparation, can solve the problems of complex metal thermal reduction process, high safety management requirements, difficulty in achieving continuity, etc., to overcome the mass production process, solve the high safety management requirements, The effect of improving purity and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

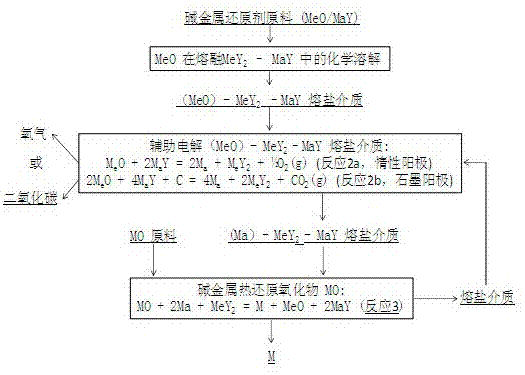

Method used

Image

Examples

Embodiment 1

[0081] Step 1 (preparation of molten salt medium):

[0082] Weigh 1.35 kg of CaCl respectively 2 and 0.65 kg of NaCl to make 2 kg of CaCl 2 / NaCl salt mixture. Put the mixed salt into the reaction vessel, and then heat it to 550-1000°C under the protection of argon atmosphere. When the above salt mixture is molten, 40-100 grams of CaO and 90-300 grams of NaCl are added to the molten salt mixture. After 0.5-2 hours, start auxiliary electrolysis. The electrolysis conditions are: use stainless steel as the cathode material, graphite as the anode material, and control the cell voltage within the range of 2-3.2 volts. When the molten salt medium is Na-NaCl-CaCl saturated with metallic sodium 2 When melted, end the auxiliary electrolysis. The electrolysis time is between 0.5-15 hours.

[0083] Step 2 (sodium thermal reduction of Ta 2 o 5 ):

[0084] The melt temperature is controlled within the range of 600-800°C, and about 50 grams of Ta 2 o 5 powder, with the support of...

Embodiment 2

[0086] Step 1 (preparation of molten salt medium):

[0087] Weigh 9.95 kg of CaCl respectively 2 and 20.05 kg of KCl to make 30 kg of CaCl 2 / KCl salt mixture. Put the mixed salt into the reaction vessel, and raise the temperature to 650-1000°C under the protection of argon atmosphere. After the above salt mixture is melted, 320-500 grams of CaO and 850-1000 grams of KCl are added to the melt respectively. After 0.5-2 hours, start auxiliary electrolysis. The electrolysis conditions are as follows: use stainless steel as the cathode and graphite as the anode, and control the cell voltage within the range of 2-3.2 volts. When the melt transforms into K-KCl-CaCl saturated with potassium metal 2 When the molten salt medium is used, the auxiliary electrolysis is terminated, and the required electrolysis time is between 0.5-15 hours.

[0088] Step 2 (potassium thermal reduction of Ta 2 o 5 ):

[0089] Under the protection of argon atmosphere, the temperature of the above mel...

Embodiment 3

[0091] Step 1 (preparation of molten salt medium):

[0092] Weigh 20.21 kg of CaCl respectively 2 and 9.79 kg of NaCl to prepare 30 kg of CaCl 2 / NaCl salt mixture. Add the mixed salt into the reaction vessel, and heat to 550-1000°C under the protection of argon atmosphere. When the above mixed salt is melted, 320-600 grams of CaO and 670-1000 grams of NaCl are added to the molten salt medium. After 0.5-2 hours, start auxiliary electrolysis. The electrolysis conditions are: use stainless steel as the cathode material, graphite as the anode material, control the cell voltage in the range of 2-3.2 volts, when the molten salt medium is converted into Na-NaCl-CaCl saturated with metal sodium 2 When melted, terminate the auxiliary electrolysis. The electrolysis time is between 0.5-15 hours.

[0093] Step 2 (sodium thermal reduction of Ta 2 o 5 ):

[0094] The melt temperature is controlled within the range of 600-1000°C. Then, under the protection of argon atmosphere, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com