Cloth inspecting machine

A cloth inspecting machine and cloth inspecting technology, applied in the field of cloth inspecting machines, can solve the problems of affecting winding, cloth damage, sinking into pits on both sides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

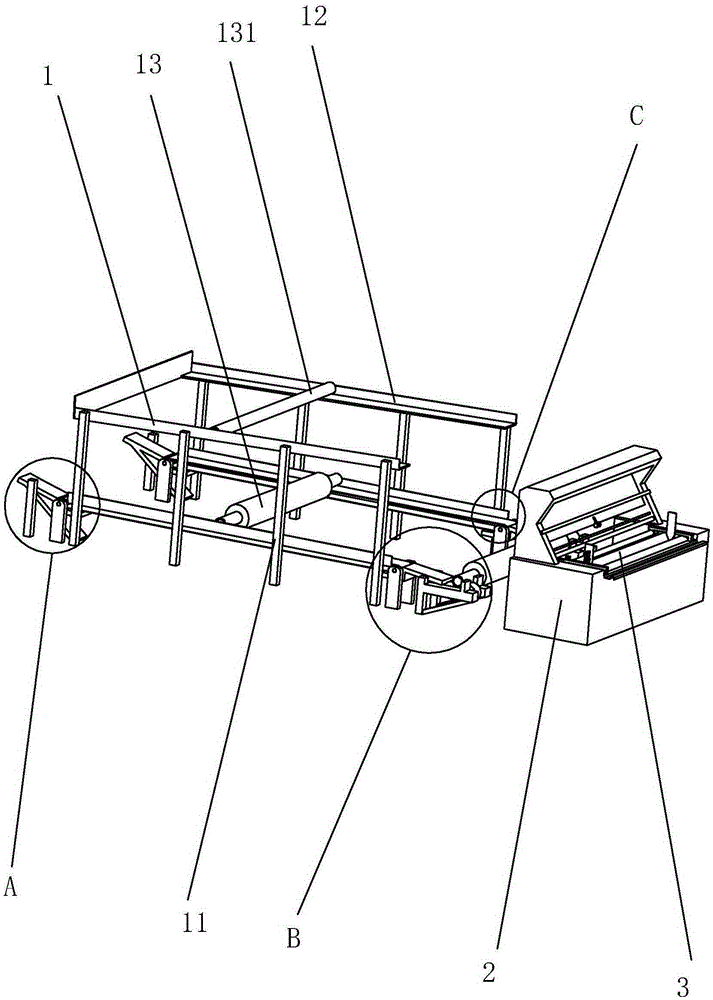

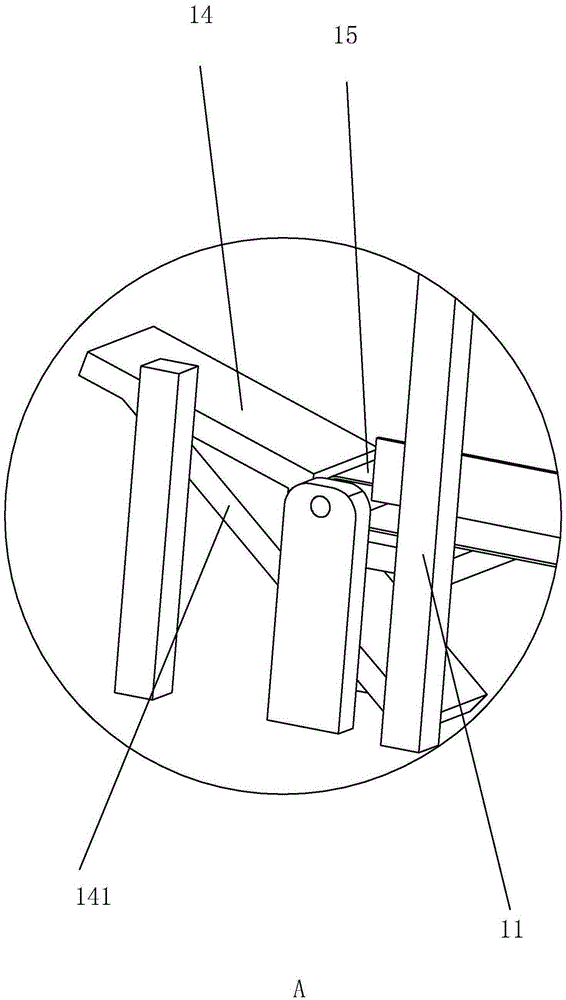

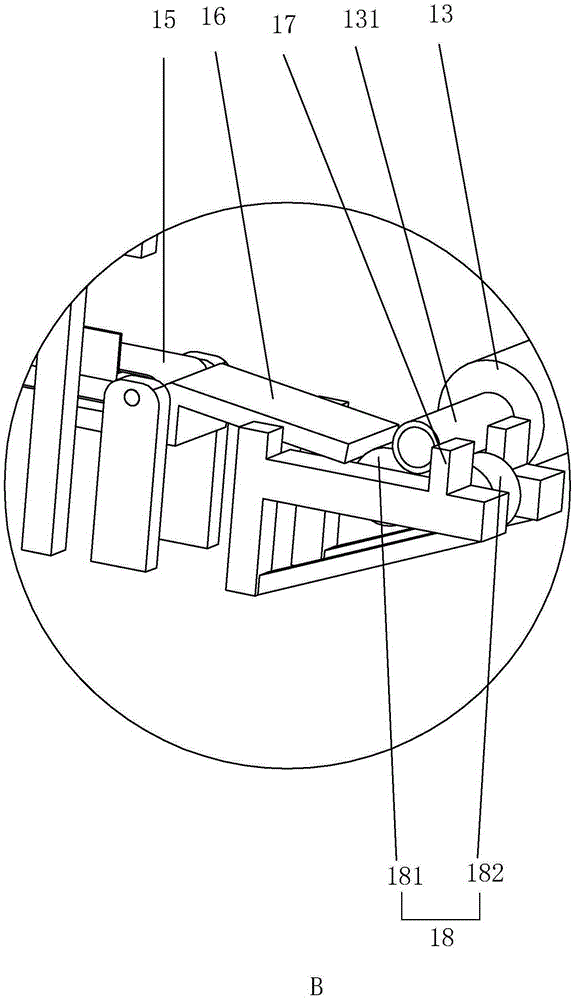

[0031] The embodiment of the cloth inspecting machine of the present invention will be further described with reference to the accompanying drawings.

[0032]A cloth inspection machine, comprising a winding mechanism 1, a cloth inspection mechanism 2, and a winding mechanism 3. Uninspected cloth rolls 13 are unwound from the winding mechanism 1, and the discharged cloth reaches the cloth inspection mechanism 2. Rewinding is carried out in the winding mechanism 3. The winding mechanism 1 includes a winding frame 11. The winding frame 11 includes a transmission assembly for placing a plurality of cloth rolls 13. One end of the transmission assembly is rotatably connected with a support roller 18 for supporting the cloth rolls 13. First, support the two ends of multiple cloth rolls 13 that need to be inspected on the transmission assembly. When the cloth rolls 13 on the support rollers 18 have been inspected, the new cloth rolls 13 are sequentially transferred to the support rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com