Crankshaft or connecting rod bearing units for internal combustion engines

A technology for connecting rod bearings and internal combustion engines, applied in connecting rod bearings, crankshaft bearings, bearing assembly, etc., can solve problems such as bearing device friction, and achieve the effect of small bearing friction and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

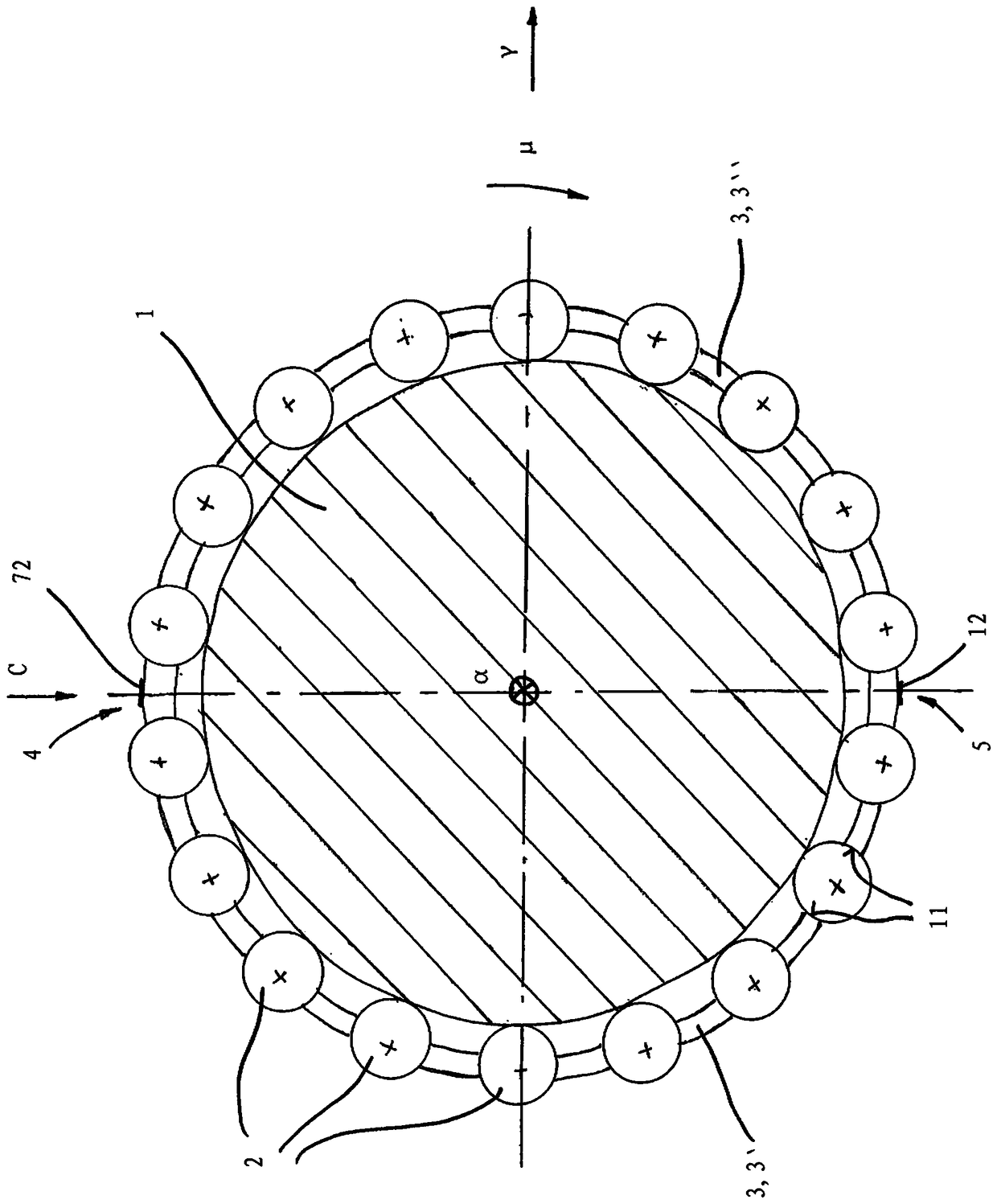

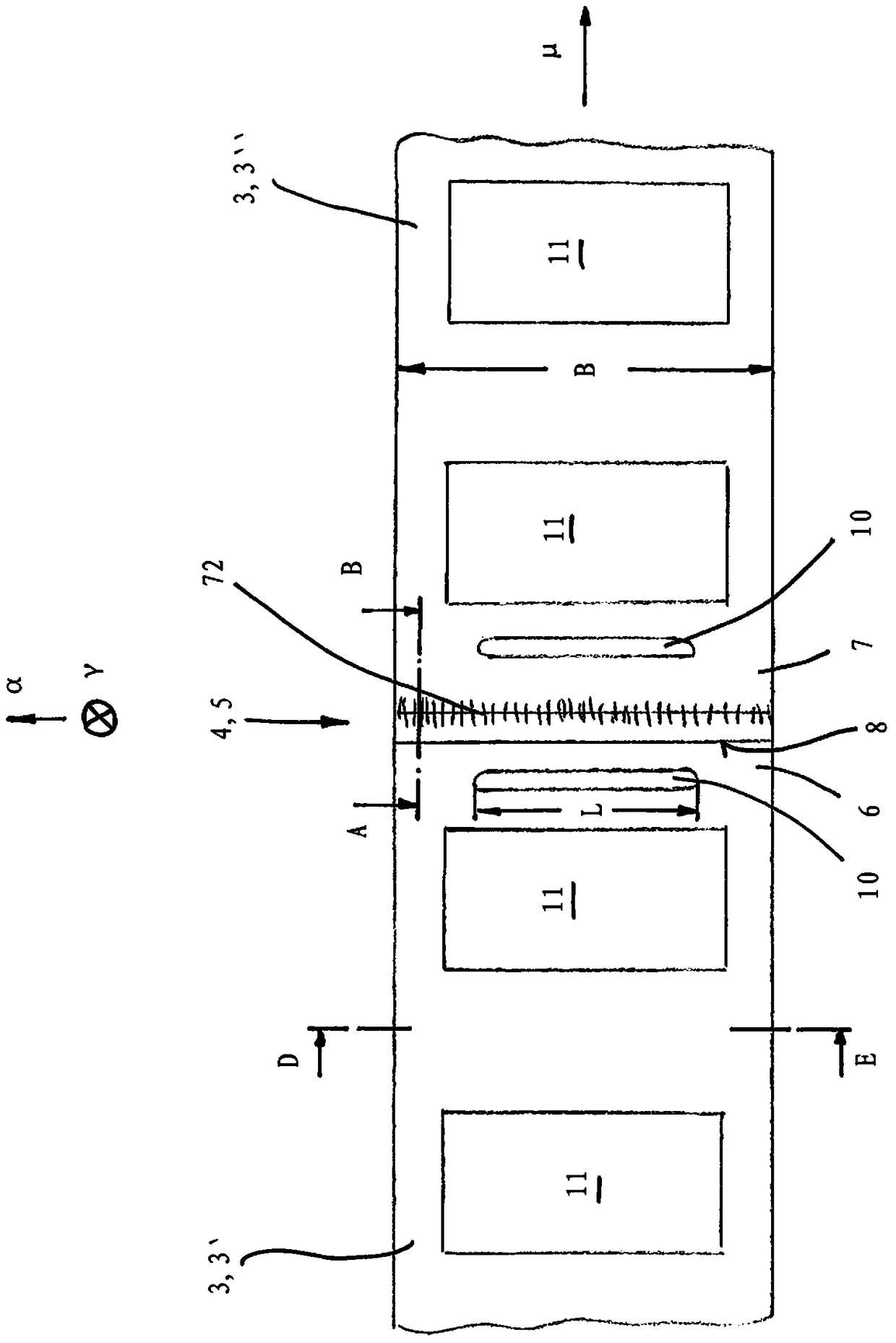

[0024] exist figure 1 shows an axial section through the journal 1 of the crankshaft of the internal combustion engine. The journal 1 of the crankshaft and the row of rolling elements which surround the journal 1 are visible. The individual rolling elements 2 are secured by a cage 3 which in the present exemplary embodiment consists of two cage segments 3 ′ and 3 ″. The two cage segments 3 ′ and 3 ″ are butted together at two abutment points 4 and 5 , which are diametrically opposite on the journal 1 . The two abutment points 4 and 5 are therefore offset by 180° in the circumferential direction U. Also documented are the radial direction r and the axial direction a, where the latter is in figure 1 perpendicular to the plane of the drawing.

[0025] The two cage segments 3' and 3'' have a plurality of receiving pockets 11 into which the rolling elements 2 are respectively inserted.

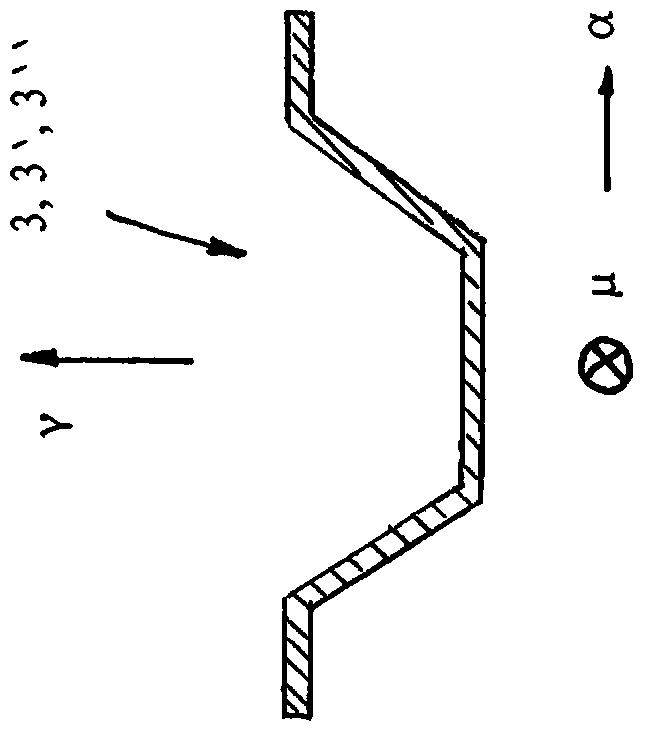

[0026] look at figure 2 and 4 It can be seen that the two cage segments 3 ′ and 3 ″ are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com