Novel heat shrinking sleeve

A heat-shrinkable, new technology, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problems of product quality decline, low automation level, backward technology, etc., to improve production efficiency, simplify production process, The effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following further description in conjunction with the accompanying drawings does not limit the scope of the present invention.

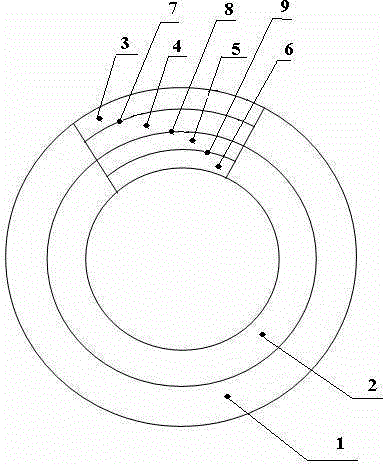

[0015] see figure 1 and figure 2 As shown, the structure of the present invention is a hollow columnar structure, and its cross-section is an annular structure. This structure includes a base material layer 1 and a hot melt adhesive layer 2, and a base material melt adhesive connection layer 8 is arranged between them, so that it The structure is more stable and has a higher shrinkage rate. The annular structure also includes a special stabilizing layer. This stabilizing layer contains at most seven thin layers, which are the outer layer 3 of the base material end, the inner layer 4 of the base material end, Melt glue end outer layer 5, melt glue end inner layer 6, base material connecting layer 7, base material melt glue connecting layer 8 and melt glue connecting layer 9, between base material end outer layer 3 and base material end in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com