Photoresist bottle holding device

A technology for holding devices and photoresist bottles, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. lack of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

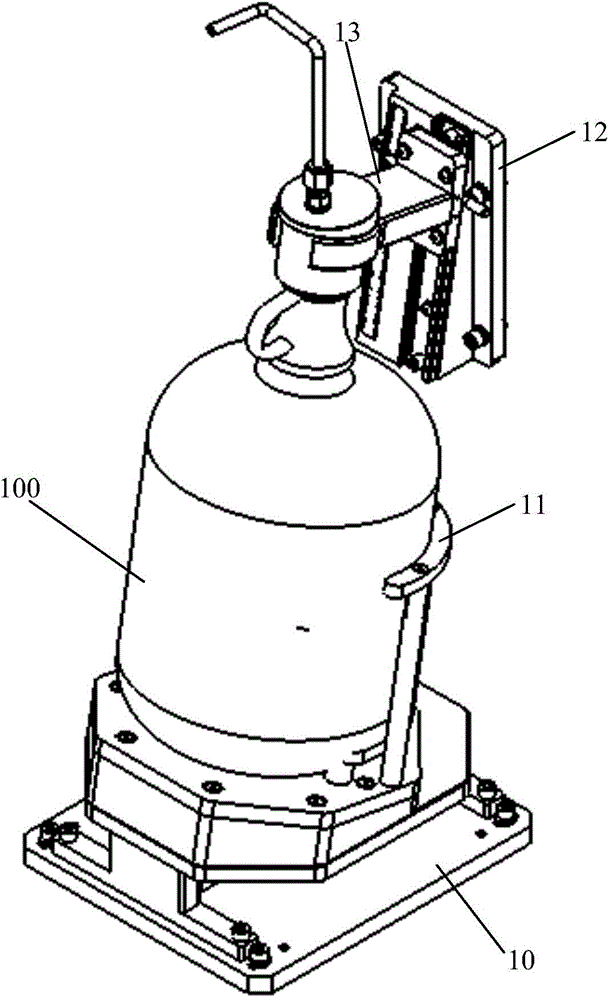

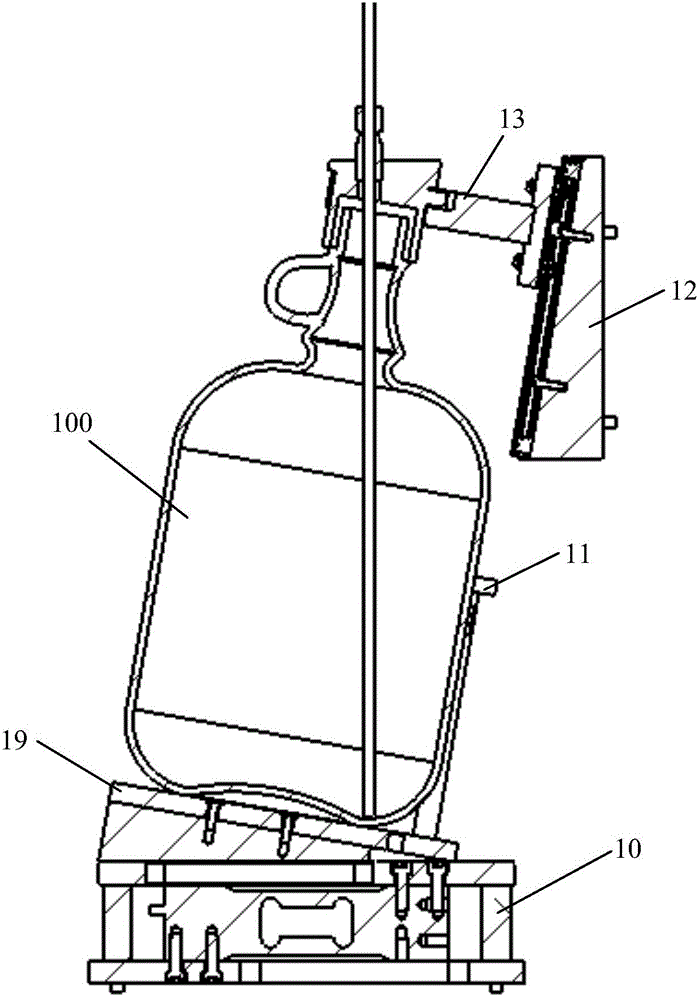

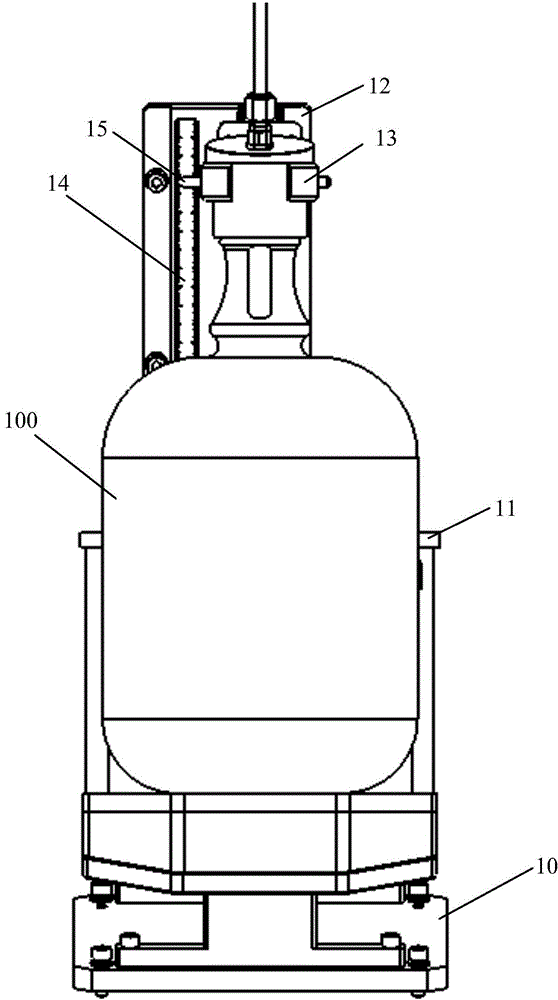

[0028] The photoresist bottle holding device of this embodiment includes a base, a large bottle holder, a small bottle holder, a straw holder, a straw clamping arm, a fine-tuning scale, a scale pointer and a support plate.

[0029] Among them, the large bottle holder is fixedly connected with the base, and the large bottle holder is used to support the large bottle (abbreviation of "big photoresist bottle"). Furthermore, the first support surface of the large bottle holder is used to support the large bottle. The shape of the support surface is adapted to the shape of the side wall of the carboy.

[0030] The vial holder is detachably connected to the first support surface of the large bottle holder, and the vial holder has a second support surface and a third support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com