Hollow heat pipe radiator

A heat pipe radiator, hollow technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of no hollow heat pipe development and use, low heat conduction efficiency, large radiator volume, etc. The effect of increasing the heat dissipation area and increasing the heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

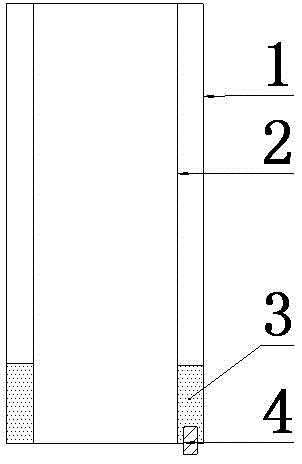

[0023] like Figure 4 , figure 1 Shown: a hollow heat pipe radiator is composed of a hollow heat pipe (6) and a heat conduction pipe (8);

[0024] The hollow heat pipe (6) is composed of an inner pipe (2), an outer pipe (1), a valve (4), and a heat-conducting working medium (3);

[0025] The outer tube (1) and the inner tube (2) are metal tubes with the same length; the upper and lower ends of the outer tube (1) and the inner tube (2) are fixed and welded together by metal plates. It is sealed and airtight; 1. The diameter of the outer tube (1) is 5mm larger than that of the inner tube (2); 2. There is a heat-conducting working medium (3) in the space between the outer tube (1) and the inner tube (2); 3. The wall thickness of the outer tube (1) and inner tube (2) needs to meet the requirements of vacuum pressure resistance and airtightness; 4. Heat dissipation fins can be added on the outer wall of the outer tube (1) to expand the heat dissipation area.

[0026] A valve (4)...

Embodiment 2

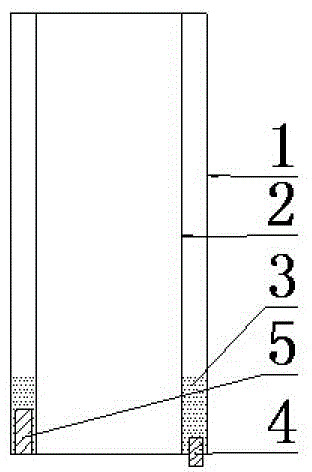

[0033] like figure 1 , image 3 Shown: a hollow heat pipe radiator is composed of a hollow heat pipe (6) and an electric heating device (4);

[0034] The hollow heat pipe (6) is composed of an inner pipe (2), an outer pipe (1), a valve (4), and a heat-conducting working medium (3);

[0035] The outer tube (1) and the inner tube (2) are metal tubes with the same length; the upper and lower ends of the outer tube (1) and the inner tube (2) are fixed and welded together by metal plates. It is sealed and airtight; 1. The distance between the outer tube (1) and the inner tube (2) is 10mm; 2. The space between the outer tube (1) and the inner tube (2) has a heat-conducting working medium (3); 3 , The wall thickness of the outer tube (1) and the inner tube (2) needs to meet the requirements of vacuum pressure resistance and airtightness; 4. Heat dissipation fins can be added on the outer wall of the outer tube (1) to expand the heat dissipation area.

[0036] A valve (4) is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com