Directly generate linearly polarized te 11 relativistic return wave tube

A relativistic return wave tube, TE11 technology, applied in the field of masers, can solve the problems of complex structure, difficult processing, low interaction efficiency, etc., achieve high conversion efficiency, simple structure, and improve beam conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the linearly polarized TE of the present invention is directly produced below in conjunction with the accompanying drawings and examples 11 The relativistic return wave tube of the mode is described in detail.

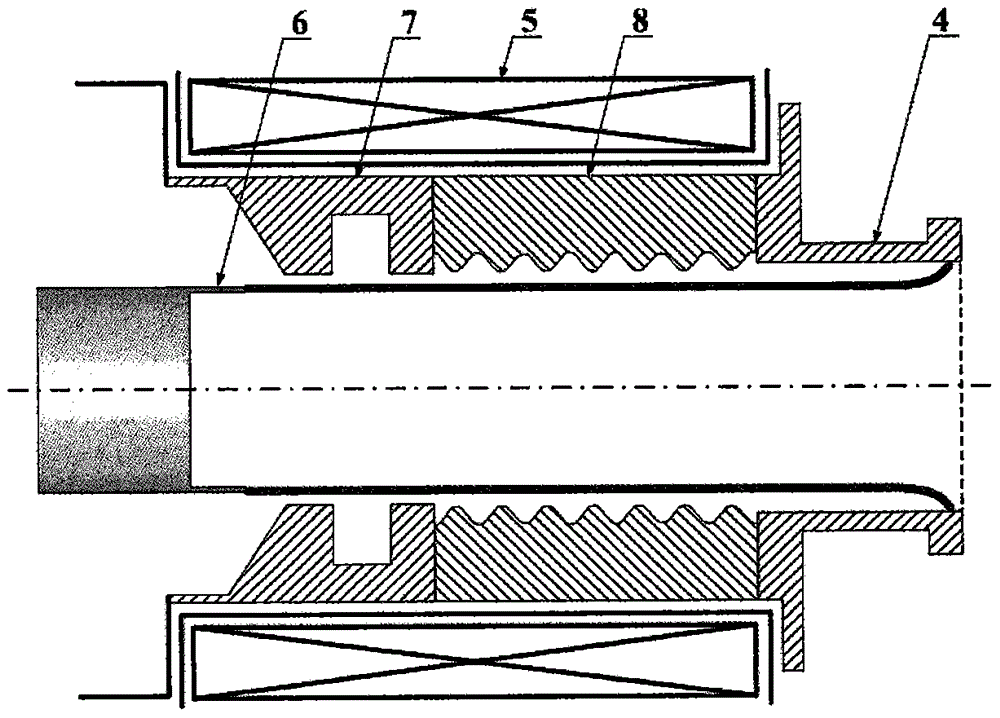

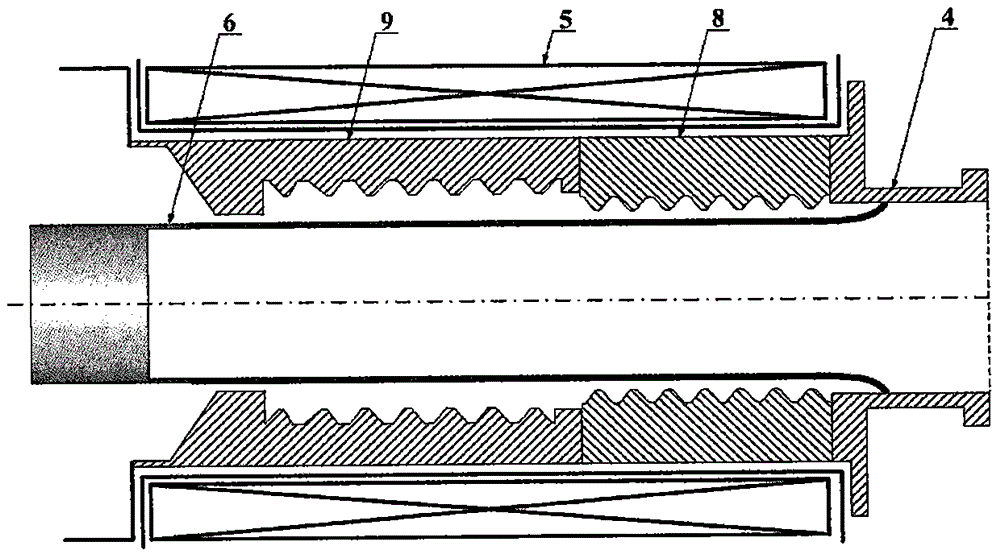

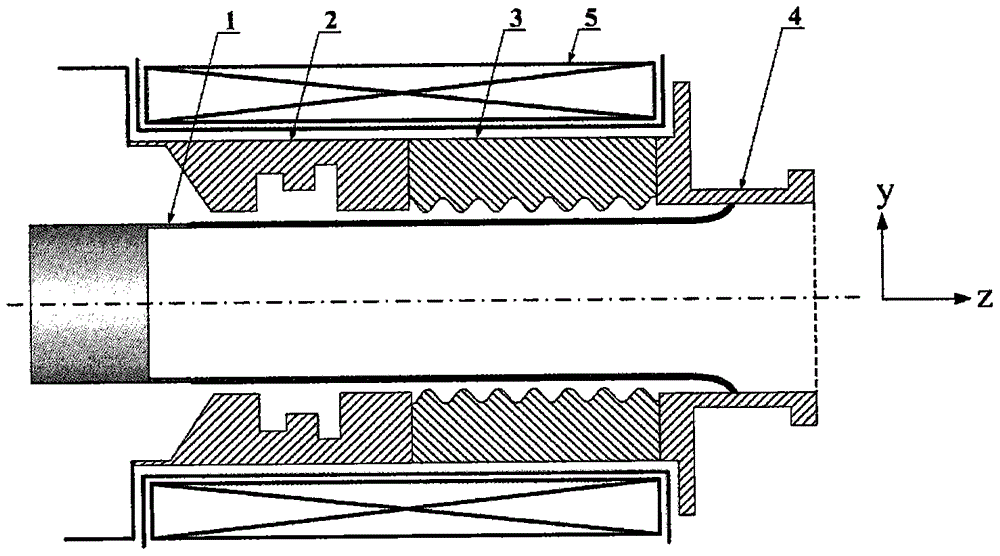

[0030] image 3 , 4 A schematic diagram of an embodiment of the present invention is given. image 3 The electron beam output direction along the central axis of the relativistic return wave tube is the z axis, the vertical z axis is the y axis, and the vertical y and z axes point to the paper surface is the x axis. image 3 is the structural representation on the yz section of this embodiment, Figure 4 It is a structural schematic diagram on the xz section of this embodiment. The relativistic return wave tube provided by the present invention includes an arc cathode 1 , a double pre-modulated cavity 2 , an angularly partitioned slow wave structure 3 , an output waveguide 4 and a magnetic field coil 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com