Light emitting device and method for manufacturing the same

一种发光装置、发光元件的技术,应用在照明装置、印刷电路制造、照明装置的零部件等方向,能够解决色调偏移等问题,达到减低色相不均的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, the embodiment will be described in detail with reference to the drawings.

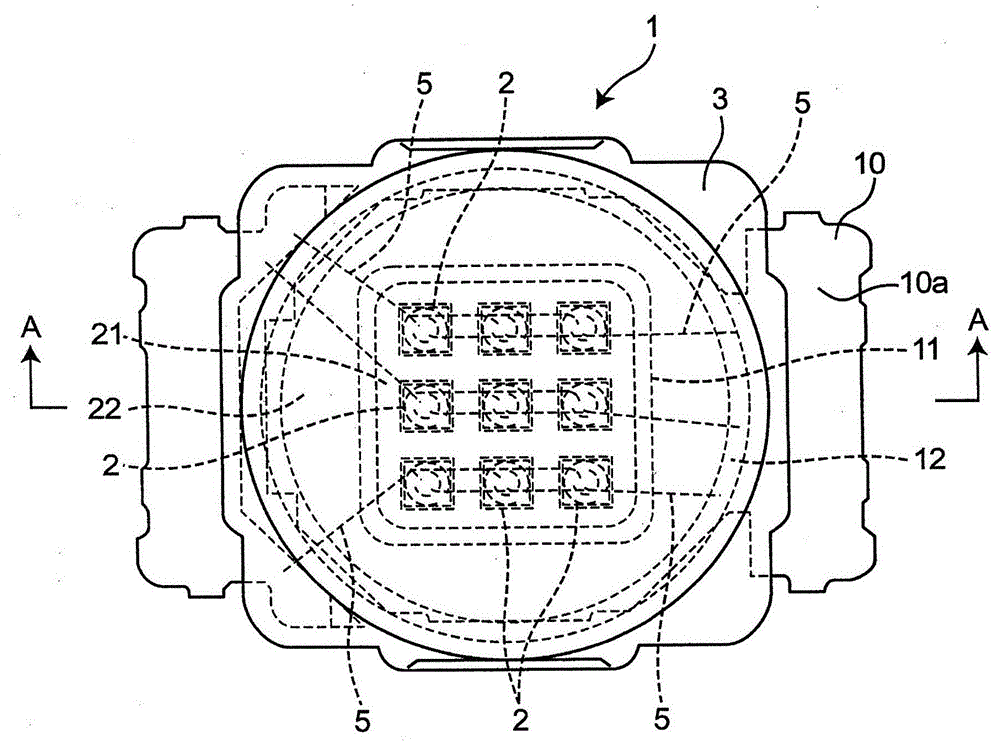

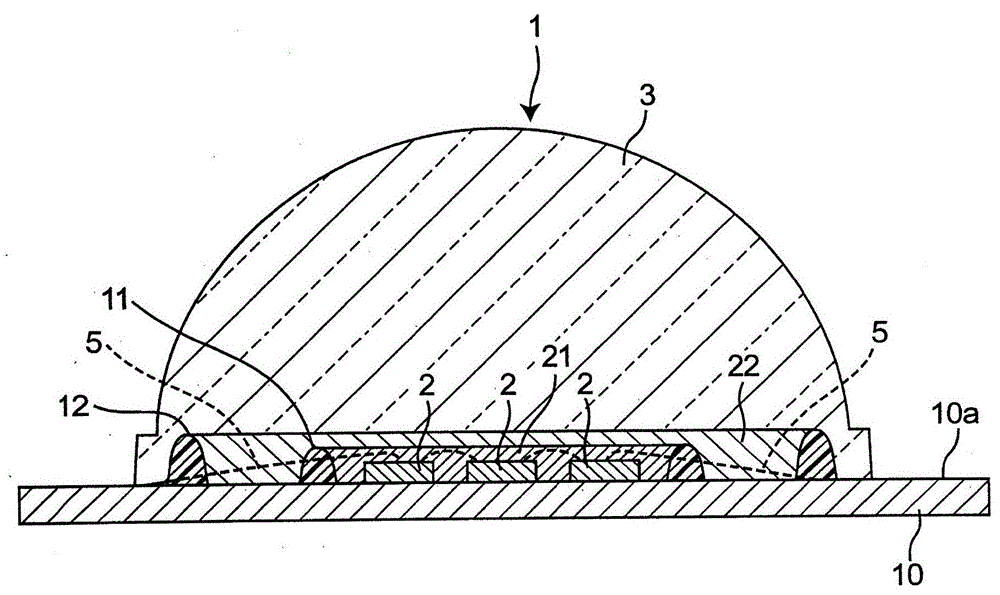

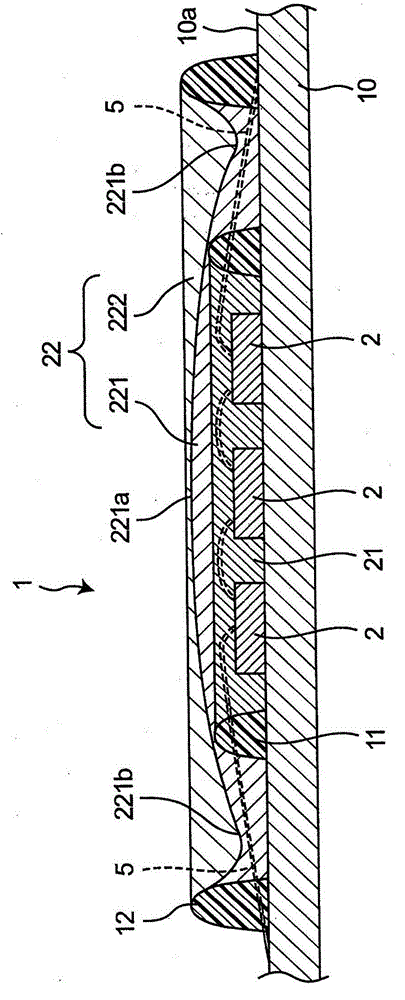

[0041] figure 1 It is a plan view showing a light emitting device according to an embodiment. figure 2 It is a cross-sectional view showing a light emitting device according to an embodiment. Figure 3A yes figure 2 Enlarged part of the image. Such as Figure 1 ~ Figure 3A As shown, the light-emitting device 1 has: a base body 10; a first frame body 11 disposed on the upper surface 10a of the base body 10; disposed on the upper surface 10a of the base body 10 and surrounding the first frame body 11 separately from the first frame body 11 The second frame 12.

[0042] The first frame body 11 and the second frame body 12 are each formed in a ring shape. A plurality of light emitting elements 2 are arranged in a region surrounded by the first frame body 11 on the upper surface 10a of the base body.

[0043] A first sealing resin 21 is arranged in a region surrounded by the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com