A soil recovery device

A frame, clamping and conveying technology, which is applied in the direction of harvesters, digging harvesters, agricultural machinery and implements, etc., can solve the problems of large footprint, inability to realize soil removal function, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

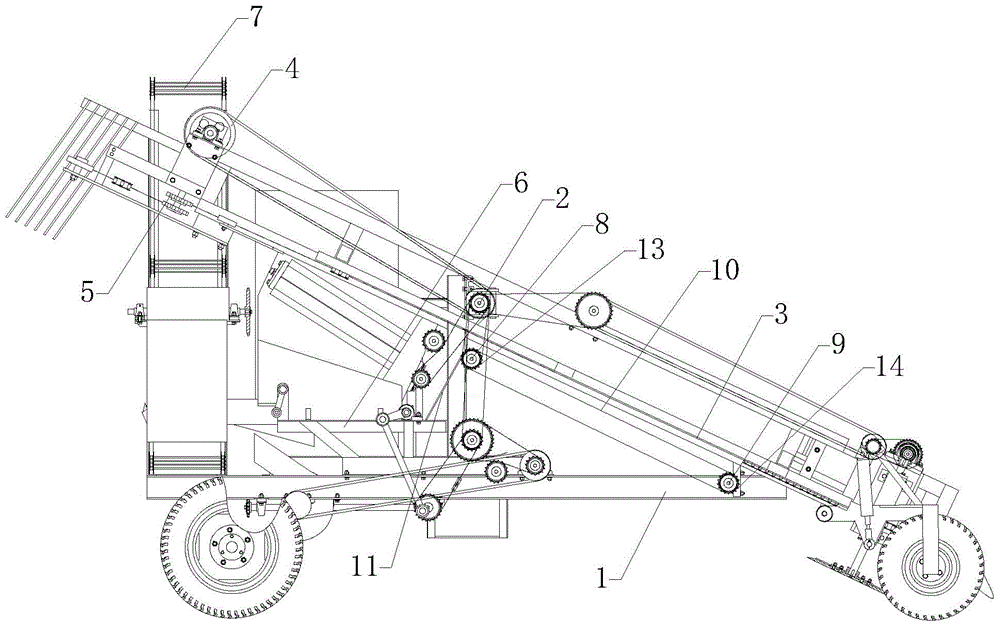

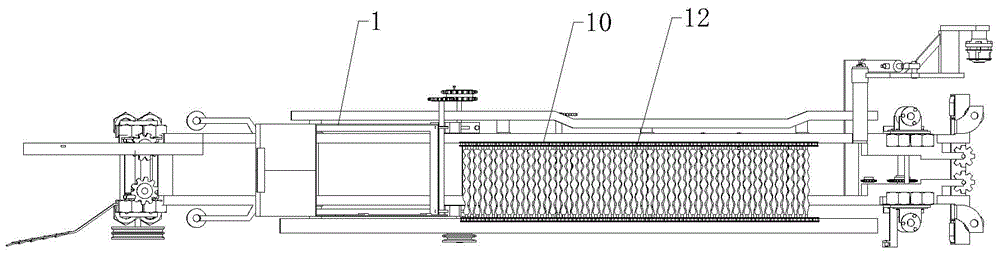

[0026] The soil removal and recovery device is used for soil removal and recovery during the harvesting of root crops.

[0027] Such as figure 1 and figure 2 As shown, it includes a frame 1, a clamping conveying device 3 and a soil removal device. The power mechanism of the soil removal and recovery device is connected with a power output shaft 2, the front end of the frame 1 is provided with a digging shovel, and the front and rear ends of the frame 1 are provided with a clamping and conveying device 3. After the digging shovel digs out the crops, the clamping conveying device 3 clamps the harvested fruit seedlings, and the fruit is transported from the front end of the frame 1 to the rear end.

[0028] From the front end to the rear end of the frame 1, the clamping and conveying device 3 can be parallel to the ground or inclined upward.

[0029] The power output shaft 2 is the power source of the whole soil removal and recovery device, which provides power for the vibrat...

Embodiment 2

[0037] Different from the above-mentioned embodiments, from the front end to the rear end of the frame 1, the clamping and conveying device 3 is an inclined upward structure. 3 The spacing gradually decreases.

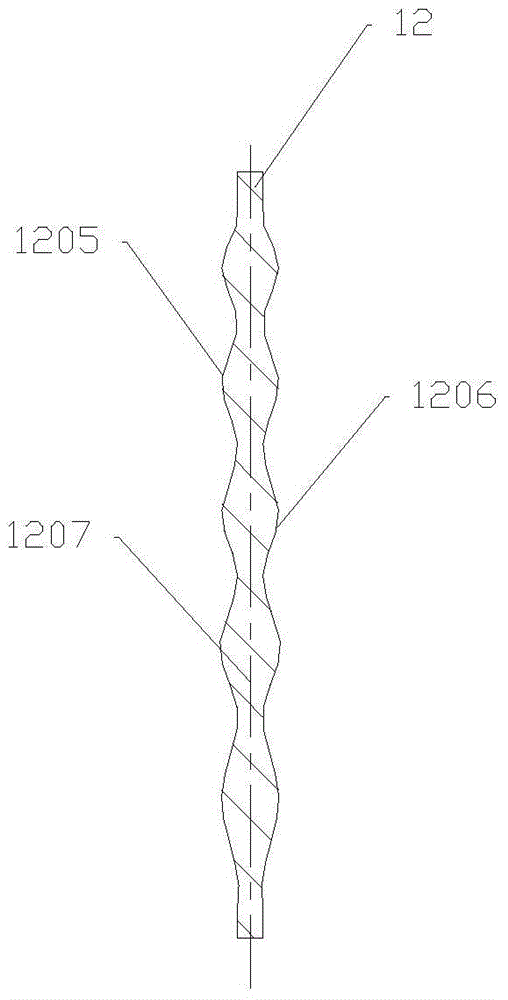

[0038] The angle between the plane where the soil removal rollers 12 are arranged and the plane where the clamping and conveying device is located is 8°, that is, both planes extend upwards, and the intersection is at an angle of 8°.

[0039] Compared with two parallel planes, it can ensure that the soil removal roller 12 keeps in contact with the clamped fruit during the whole clamping and conveying process, which can further reduce the soil content and fruit leakage rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com