A Microsphere Turner

A flipper and microsphere technology, applied in the field of microsphere flippers, can solve the problems of difficult precise docking of PVA coating interval boundaries, poor uniformity of PVA coating, etc., and achieve the effects of easy control, peaceful conditions, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

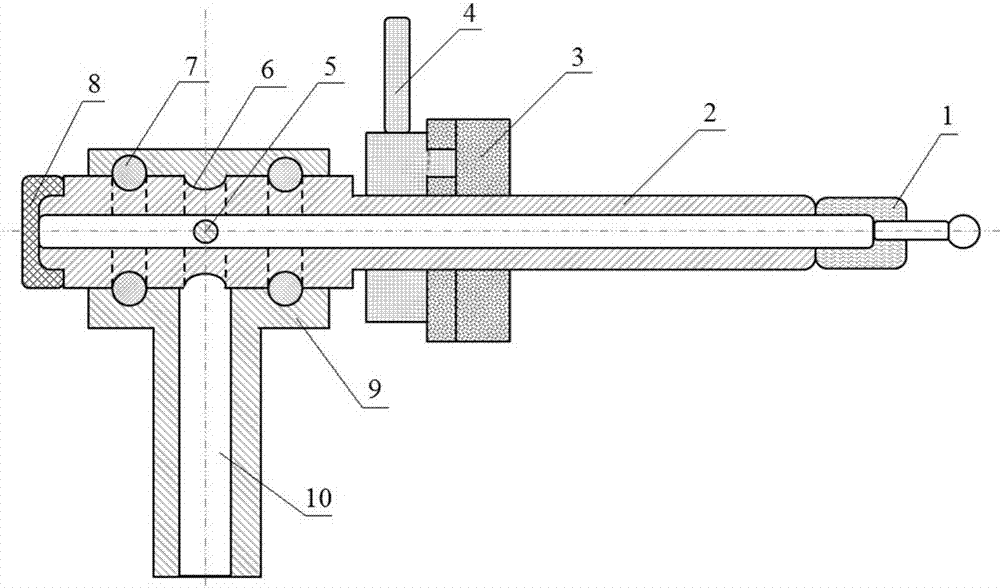

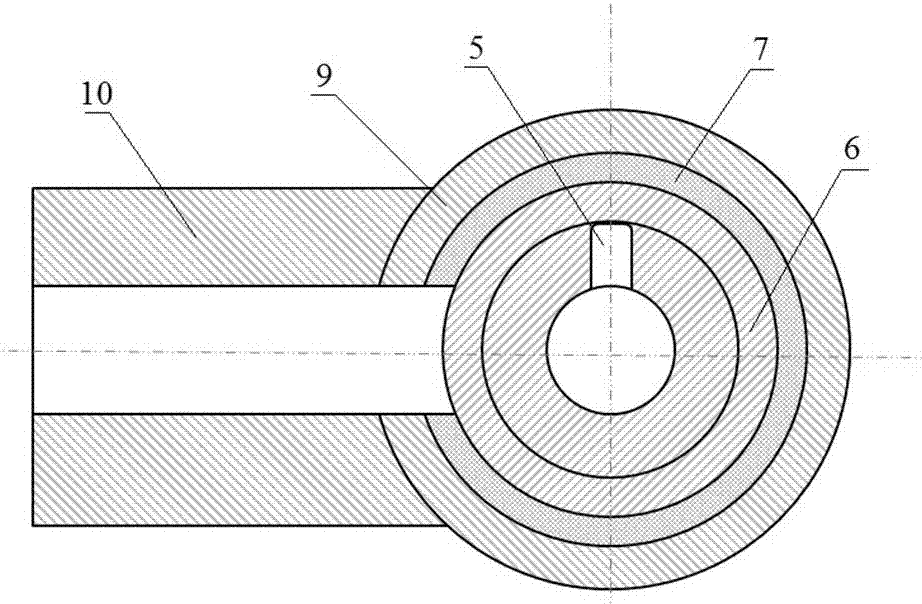

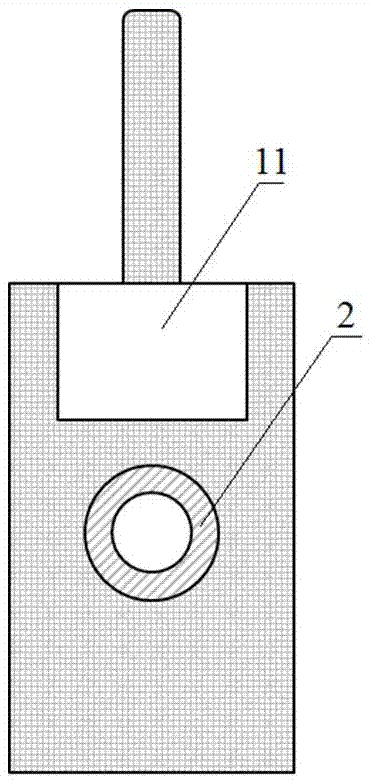

[0020] Such as figure 1 and figure 2 As shown, the microsphere flipper of the present invention includes a holder 1, a rotating shaft 2, a positioning platform 3, a turning handle 4, a dynamic sealing structure, a sealing cover 8, a negative pressure interface 10 and auxiliary parts, wherein the rotating shaft 2 is hollow Convex cylindrical tube plastic construction. The holder 1 is installed on one end of the rotating shaft 2, and the inner diameter of the capillary in the holder 1 is determined according to the diameter of the PS single-layer ball to be coated. Sealing cap 8 is a screw cap that contains rubber gasket, is installed on the rotating shaft 2 other ends, so that remove the blockage in rotating shaft 2 pipes. The rotating shaft 2 runs through the dynamic sealing structure, the turning handle 4 and the positioning platform 3 . The sealing ring 7 is compressed by the rotating shaft 2 and the fixed cavity 9 to form a dynamic sealing structure. An annular groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com