Stone strike resistant locomotive drivers' cab

A technology for smashing locomotives and cabs with stones, applied in locomotives and other directions, can solve problems such as endangering the safety of drivers and passengers, throwing stones to smash locomotives, and lack of protective measures, and achieves the effects of reducing maintenance costs, improving safety, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

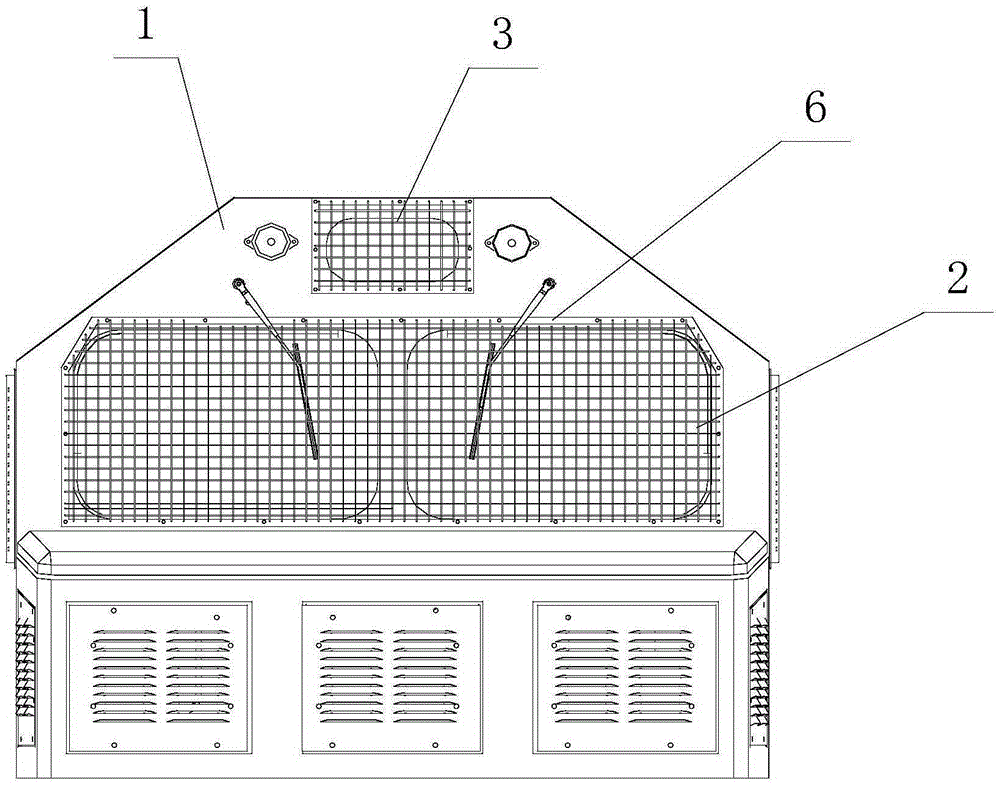

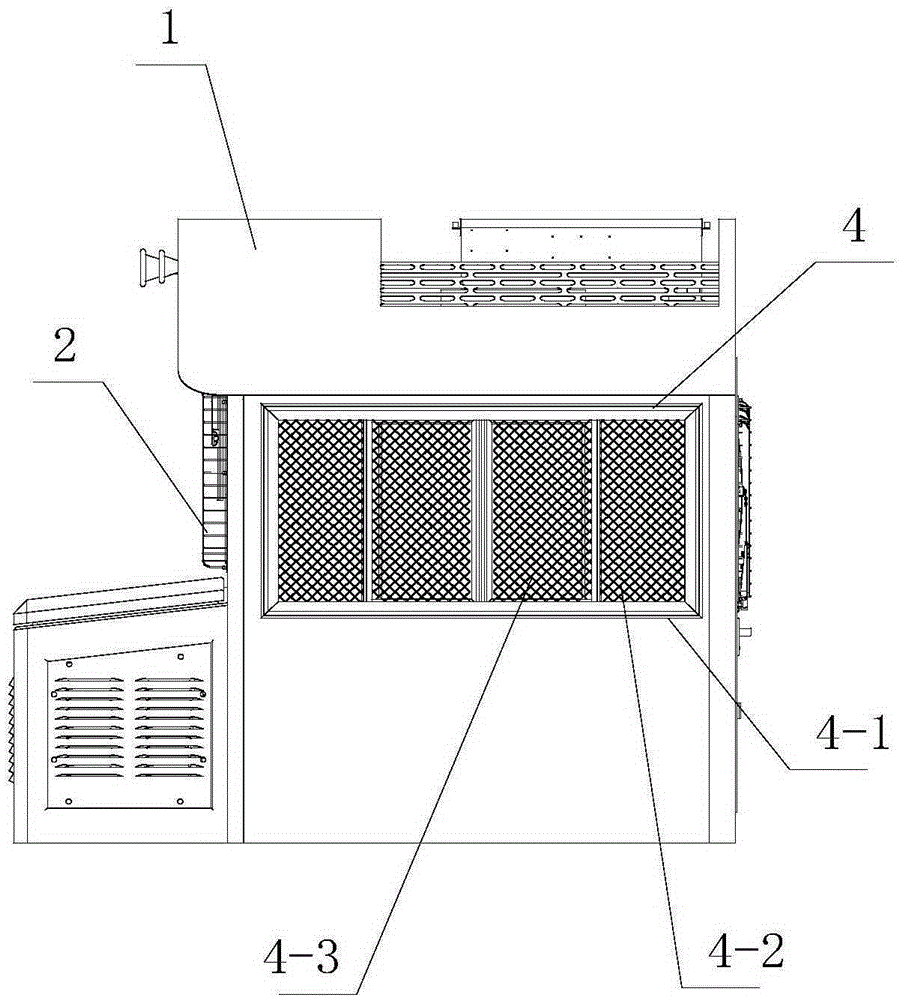

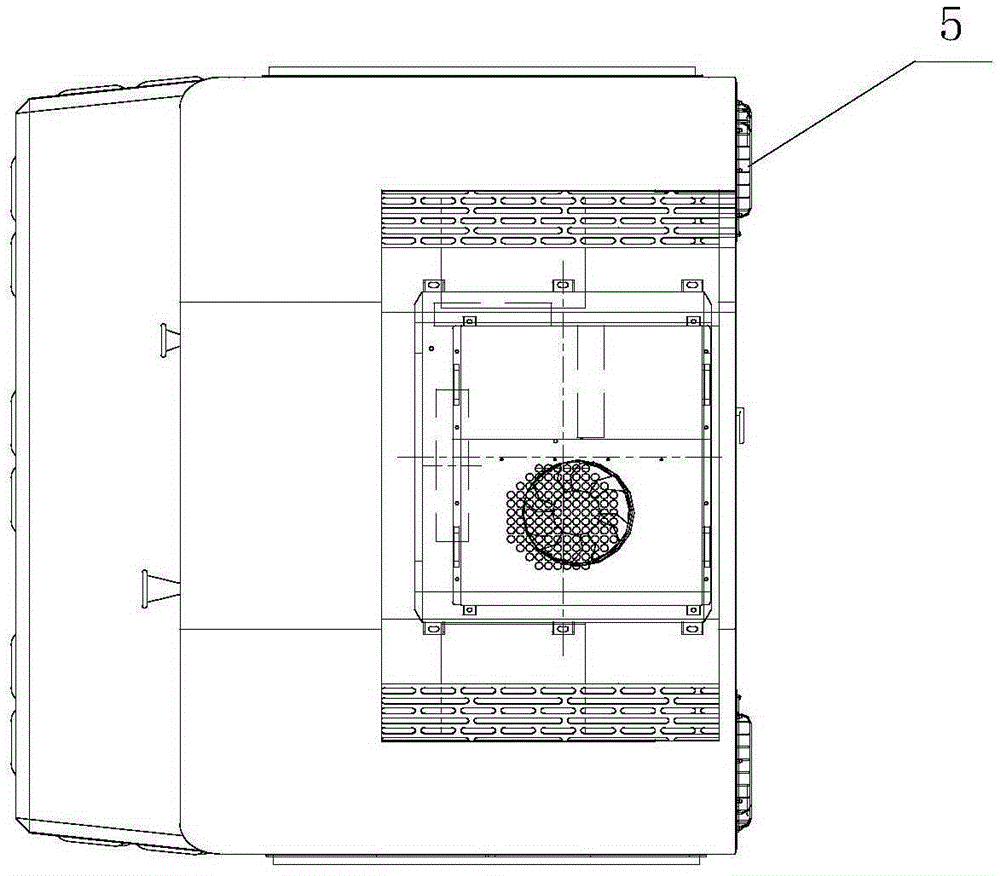

[0021] see Figure 1 to Figure 3 As shown, a kind of anti-rocking locomotive driver's cab includes a driver's cab main body 1, a front window and a headlight box are provided on the front of the driver's cab main body 1, side windows are provided on the side, and a driver's cab door is provided on the back side. The front window protective net 2 is arranged, the headlight box is provided with the headlight box protective net 3 outside, the side window is provided with the side window protective net 4, and the driver's cab door is provided with the door protective net 5.

[0022] The door protective net 5 is made of stainless steel rods. The headlight box protective net 3 is made of stainless steel. The top of the front window protective net 2 is provided with a wiper movable opening 6 .

[0023] The side window protection net 4 includes an alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com