A Method for Measuring Rail Corrugation Using Axlebox Vibration and Shock Information

A technology of information measurement and corrugation, which is applied in the direction of railway vehicle shape measuring devices, railway car body parts, railway auxiliary equipment, etc., and can solve problems such as unguaranteed measurement accuracy, weak acceleration signals, and failure to reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

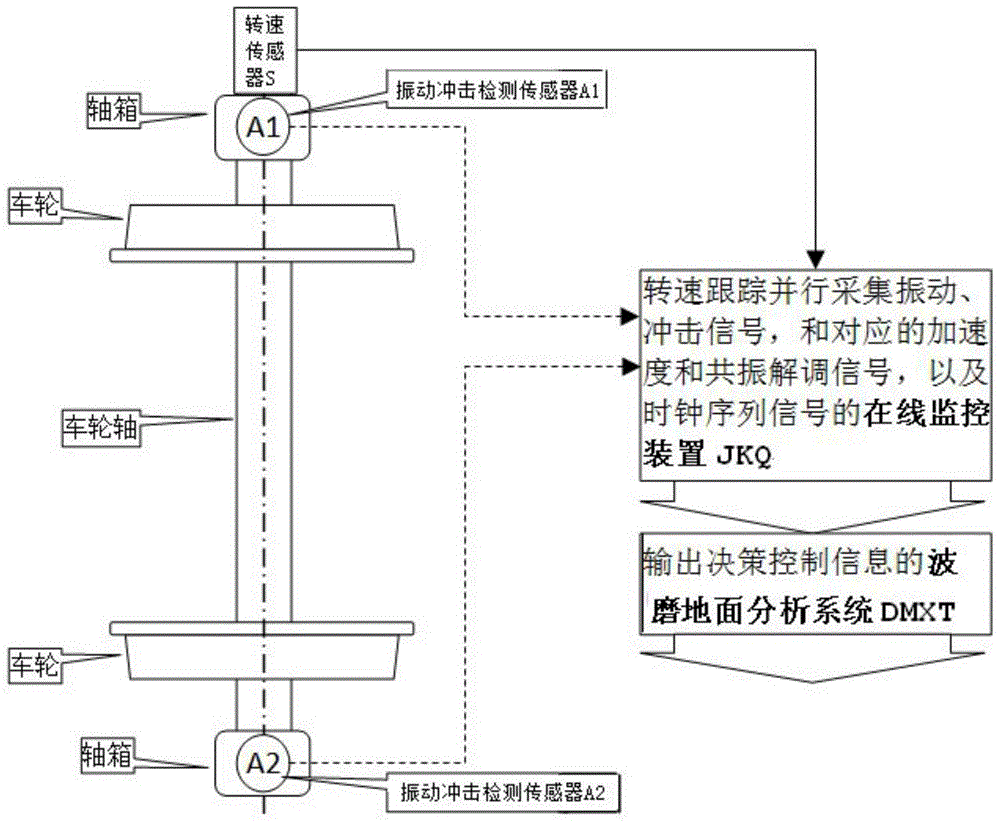

[0038] refer to figure 1 , the method for measuring track corrugation with axlebox vibration and impact information of the present invention, its vibration and impact information acquisition device includes a speed sensor S installed on the wheel-to-axle of the operating vehicle, and is installed on the axlebox bearing seats at both ends of the wheel-to-axle The vibration shock detection sensor A1 and the vibration shock detection sensor A2 on the vehicle, the on-line monitoring device JKQ installed on the vehicle and the corrugated ground analysis system DMXT that receives the data downloaded from the online monitoring device JKQ and continues to analyze, the speed sensor S, vibration The shock detection sensor A1 and the vibration shock detection sensor A2 are connected to the online monitoring device JKQ: the output signals of the vibration shock detection sensor A1 and the vibration shock detection sensor A2 are connected to the vibration monitoring channel of the online m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com