A furnace tube rotation and intermittent feeding type display rack

A technology for placing racks and furnace tubes, applied in the directions of transportation, packaging, rollers, etc., can solve the problems of poor rigidity, fast heat dissipation of furnace tubes, low operation efficiency, etc., and achieve good economic and social benefits, uniform heat dissipation and cooling, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, but not as limiting the present invention:

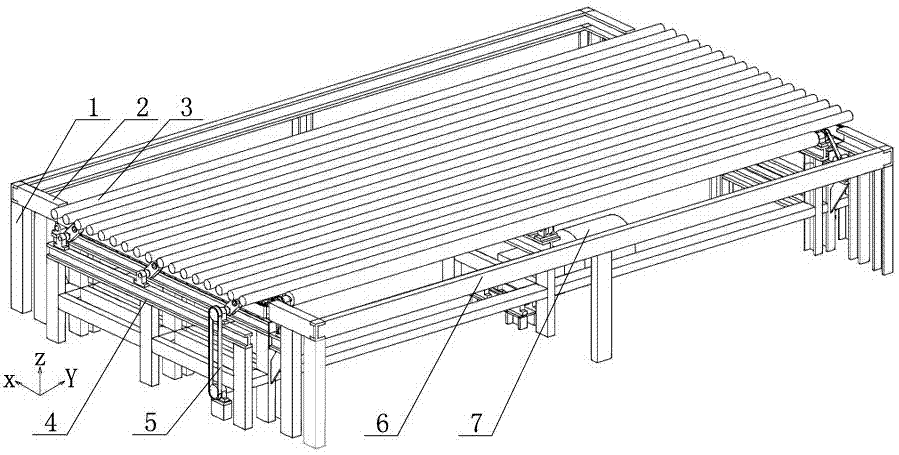

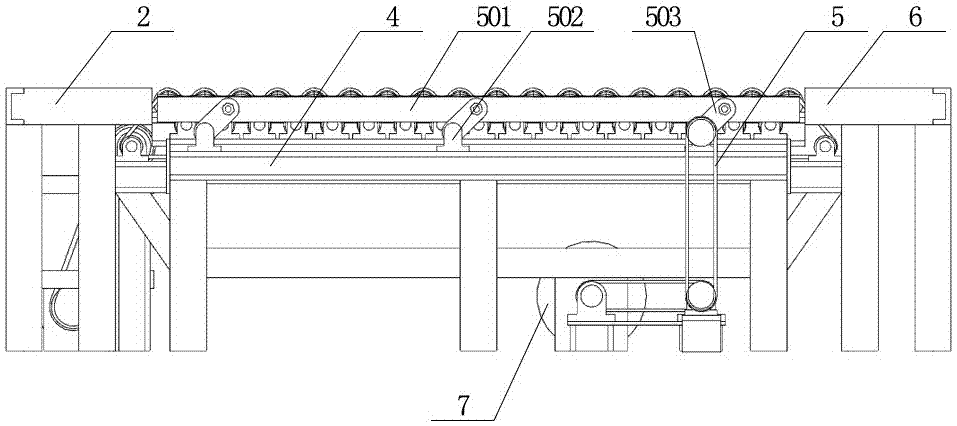

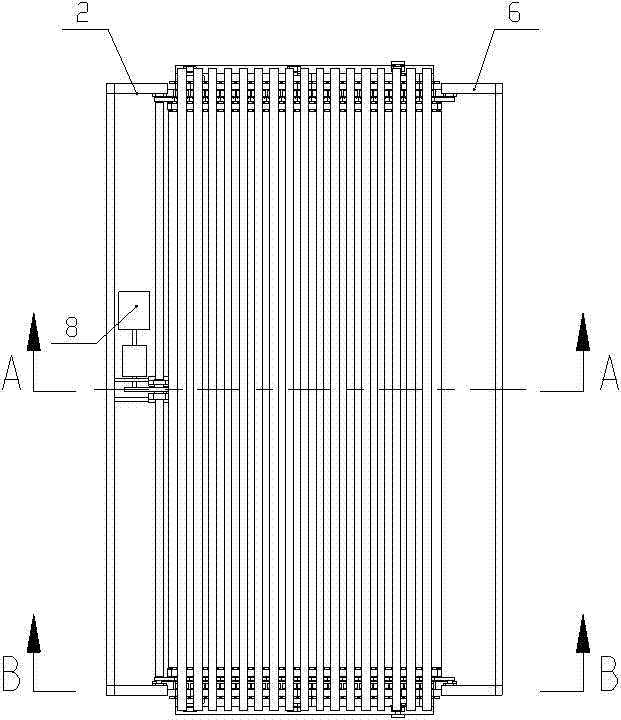

[0021]A furnace tube rotation and intermittent feeding type display rack, including a display rack 1, a power source B8 is provided at the lower left side of the placement rack 1, and the placement rack 1 is composed of the left rear guide section 2, The middle middle placement section 4 is composed of the front guide section 6 on the right side. The front guide section 6 is used to temporarily place the furnace tube 3 that has just been pulled out, and the rear guide section 2 is used to place the furnace tube 3 just removed from the middle placement section. The furnace tube 3 sent over; the middle placement section 4 is provided with support pieces symmetrically arranged front and back, and the support pieces are arranged along the X-axis direction, and the support pieces arranged symmetrically front and back are support piece A4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com