Paying-off machine

A pay-off machine and pay-off wheel technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of uneven tension, cable loose tension, damage, etc., to achieve simple structure and protection. The effect of line body and stable line supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

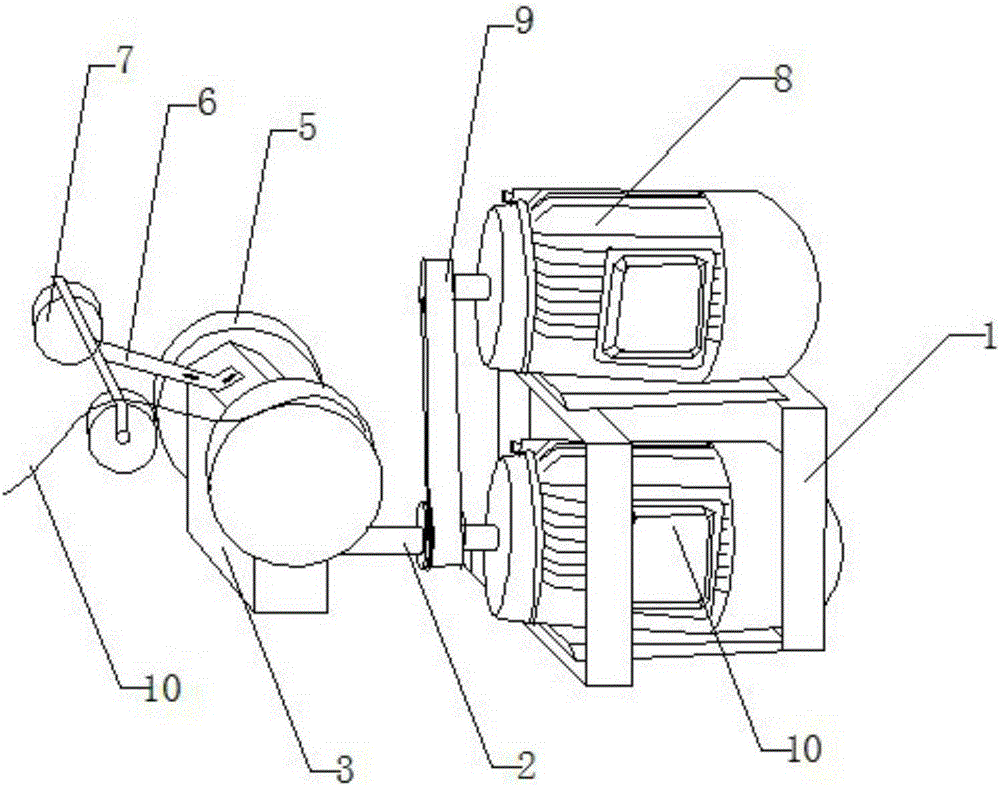

[0023] Such as figure 1 The pay-off machine shown includes a frame 1, a power mechanism arranged on the frame, a speed reducer 3 connected with the power mechanism through a transmission shaft 2, and a speed reducer 3 connected with the speed reducer 3 through a rotating shaft (not shown). A pay-off wheel 5; a fixed frame 6 is installed on the front side of the pay-off wheel 5; driven wheels 7 are arranged on both sides of the fixed frame 6.

[0024] The power mechanism includes a first motor 8 and a second motor 10 arranged below the first motor 8 and connected to the first motor 8 through a belt 9 .

[0025] Wires 11 are wound on the pay-off wheel 5 .

[0026] The working principle of the pay-off machine of the present invention: the first motor and the second motor are connected by a belt, and the second motor drives the reducer to run through the transmission shaft. The moving wheel realizes automatic adjustment, which can well protect the wire body during use, and at th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap