Novel low-energy-consumption cracking furnace and method for cracking polyethylene into wax

A cracking furnace and low energy consumption technology, which is applied in the field of polyethylene cracking into wax in a new type of low energy consumption cracking furnace, can solve the problems of energy saving and emission reduction policy inconsistency, high cost of production equipment, high temperature material leakage, etc., and achieve economical purchase of equipment The effect of high cost, high production efficiency and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a novel low-energy-consumption cracking furnace and a method for cracking polyethylene into wax. The equipment is simple to invest, can save the cost of purchasing equipment, has low energy consumption, high continuous production efficiency, advanced technology and feasible, low investment, and raw materials Widespread, quick results and good prospects can achieve the goals of social, environmental and economic benefits.

[0021] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings of the specification and specific implementations.

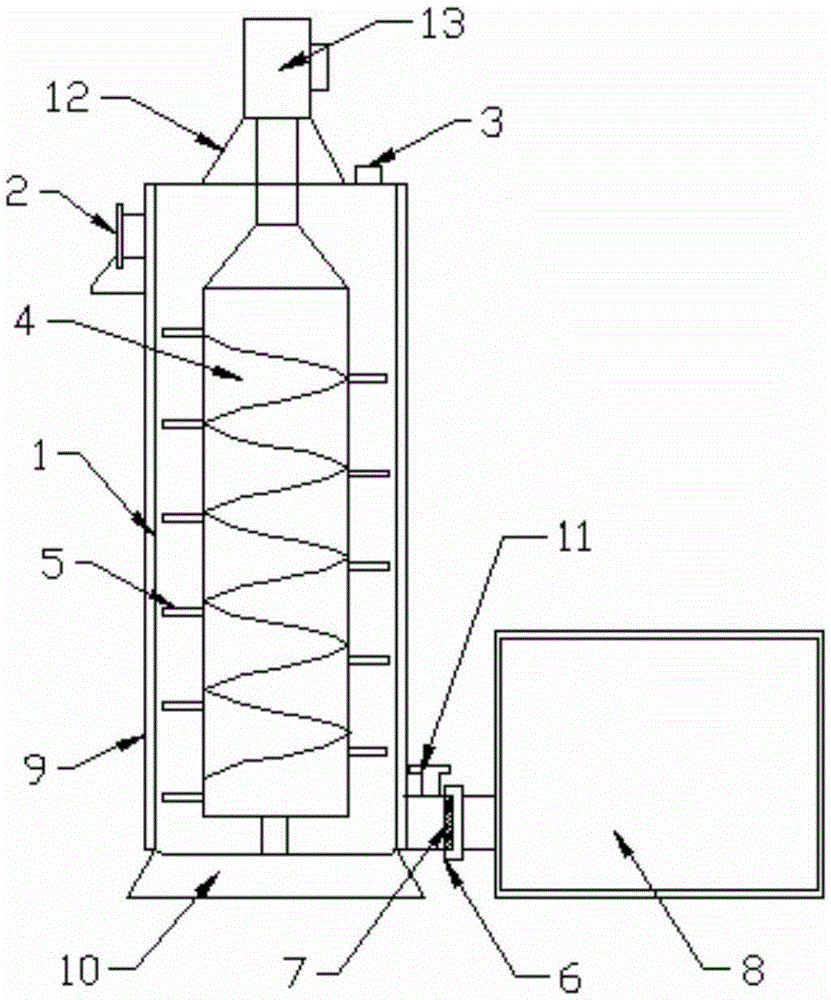

[0022] Such as figure 1 As shown, a new type of low-energy-consumption cracking furnace described in this embodiment includes a cracking furnace body 1. The upper part of the cracking furnace body 1 is provided with a feed inlet 2, and the top of the cracking furnace body 1 is provided with an air outlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com