A construction method of a concrete beam cross connection structure provided with tension reinforcement

A technology for tensioning steel bars and concrete beams, applied in building components, building structures, floor slabs, etc. The effect of mechanical performance, significant comprehensive benefit and improvement of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

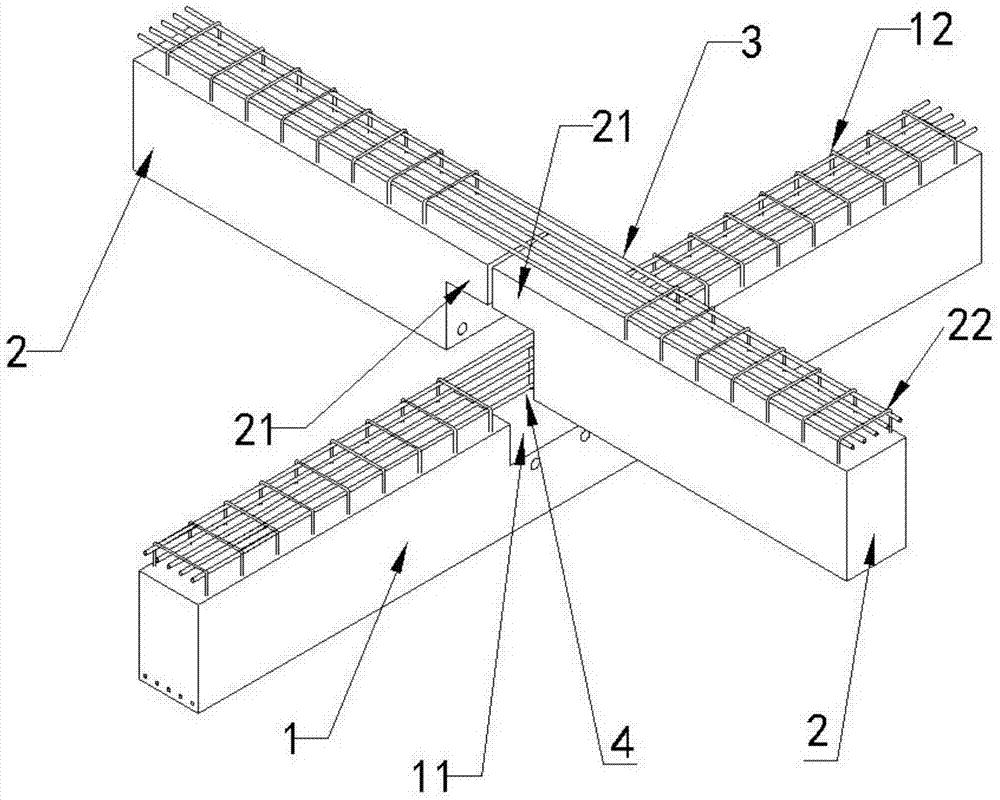

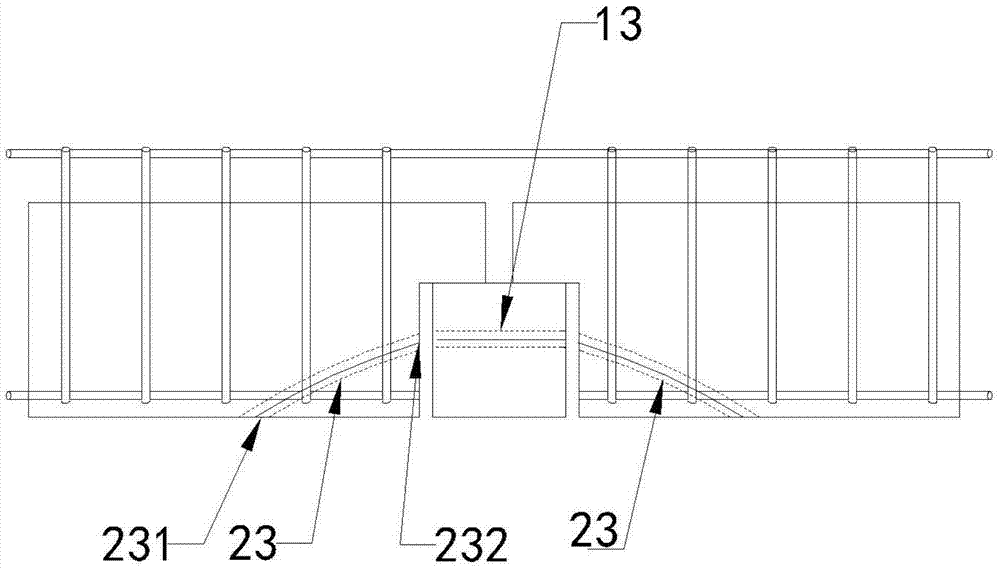

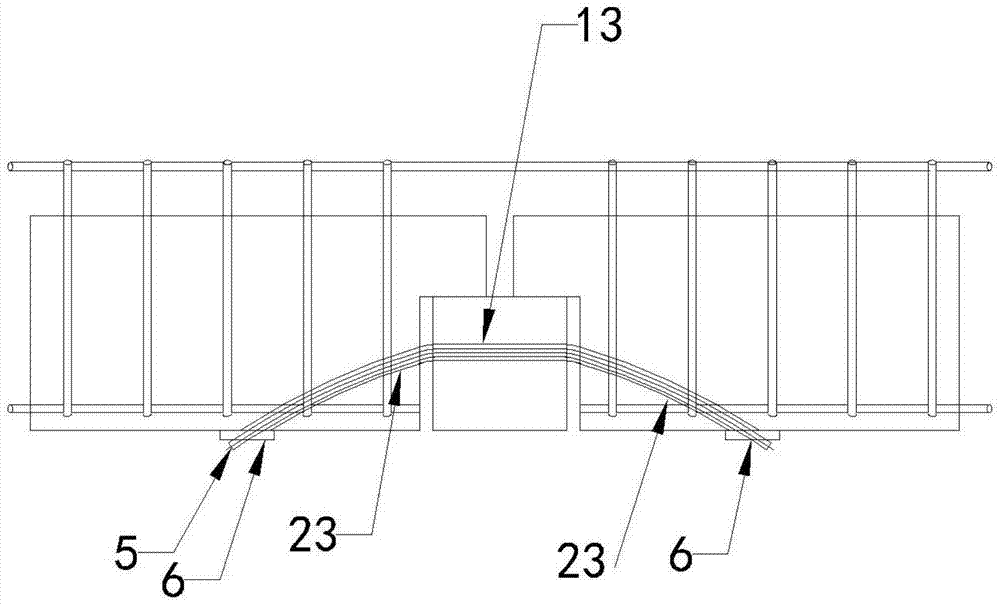

[0030] see Figure 1-4 , a concrete beam cross connection structure provided with tensile reinforcement, which includes a pre-cast concrete composite beam, the concrete composite beam includes a female beam 1 and a male beam 2, and the female beam 1 is installed between the adjacent main beams Between them, a mortise 11 extending along its thickness direction is reserved on the main body of the female beam 1, and a tenon 21 extending along the body is respectively formed on both ends of the male beam 2, and the male beams arranged symmetrically on both sides of the female beam 1 The tenons 21 of 2 are respectively inserted into the tenons and grooves 11 to form a cross structure. In order to ensure the flatness of the joint joints, in the design structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com