Monitoring structure and method for aircraft engine oil

An aero-engine and lubricating oil technology, which is applied in the direction of engine lubrication, engine components, turbines, etc., can solve the problems of a single magnetic chip detector and the inability to alarm for metal chips, so as to extend the fault warning time, reduce the cost of assembly and maintenance, and improve the The effect of monitoring capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

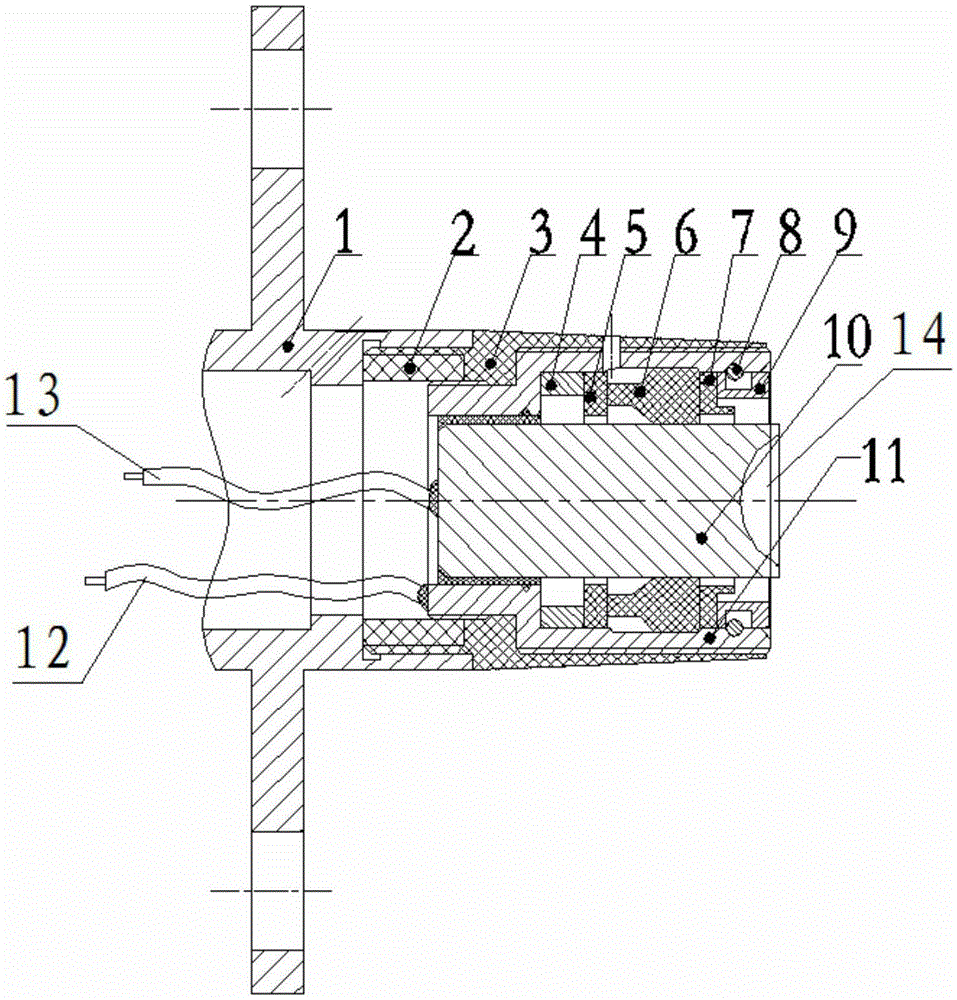

[0018] In the specific implementation process, the present invention mainly realizes the simultaneous monitoring of the metal shavings and the temperature of the lubricating oil in the lubricating oil of the aero-engine, and can perform online feedback. Such as figure 1 As shown, the aero-engine lubricating oil monitoring structure includes: housing 1, insulating sleeve 2, insulating coating 3, fusible sheet 4, gasket 5, sealing ring 6, insulating bushing 7, stop ring 8, and electrode 9 , magnet 10, outer bushing 11, etc., its main structure is:

[0019] No. 3 pin 13 in the cable plug is welded on the magnet 10 , and No. 2 pin 12 in the cable plug is welded on the outer bushing 11 . The magnet 10 is fixed in the outer bushing 11 by insulating glue, and the outer bushing 11 and the insulating sleeve 2 are bonded and connected with the casing 1 through an external thread. The insulating coating 3 is applied on the outer side of the outer bushing 11 to isolate it from the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com