Overload protector mounting structure and overload protector supports

An overload protector and installation structure technology, applied in the field of compressors, can solve problems such as the loosening of the shrapnel anti-buckle structure, and achieve the effects of high reliability, increased cost, and unchanged assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In view of the defect that the installation structure of the overload protector in the prior art is easy to loosen, the present invention considers that when the overload protector is pressed down by force, the force that the existing shrapnel buckle structure can bear is too small, so there is a possibility of loosening. Hidden danger.

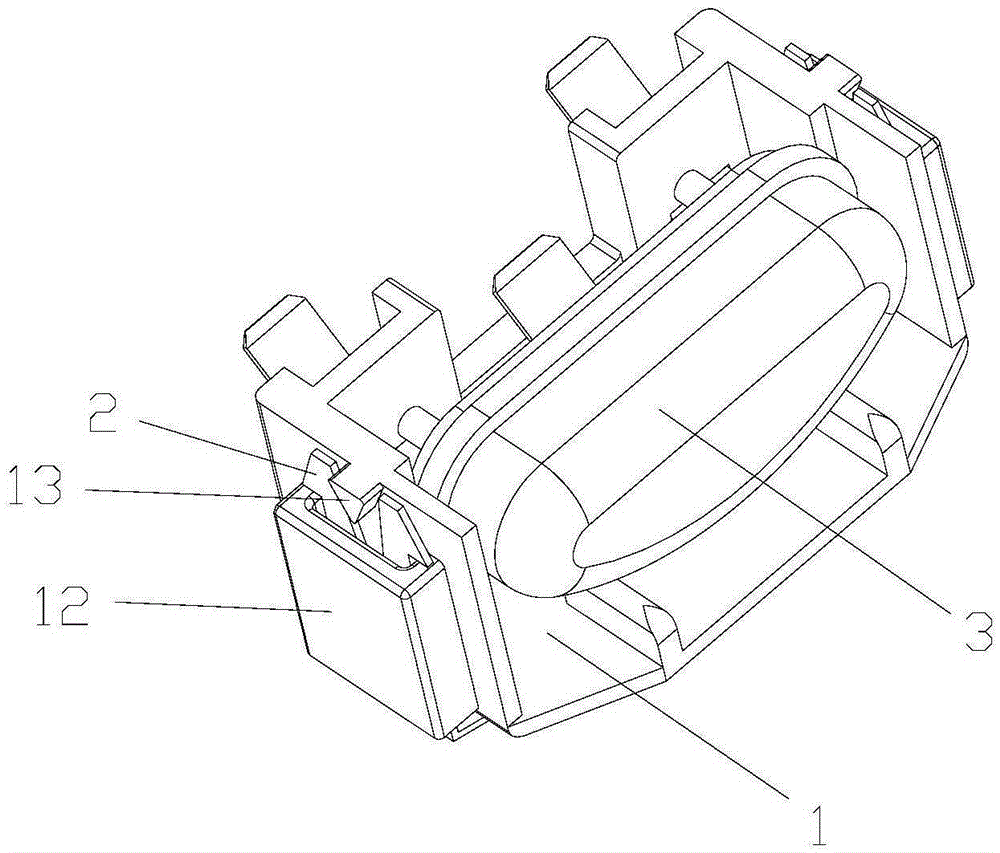

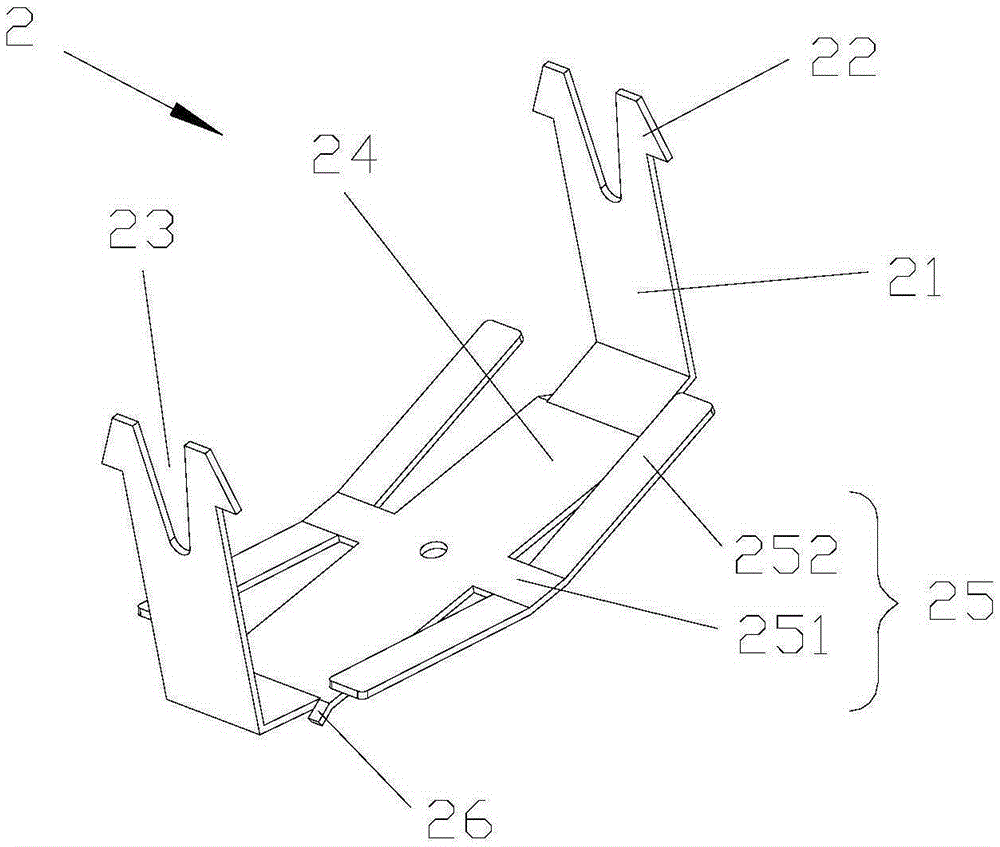

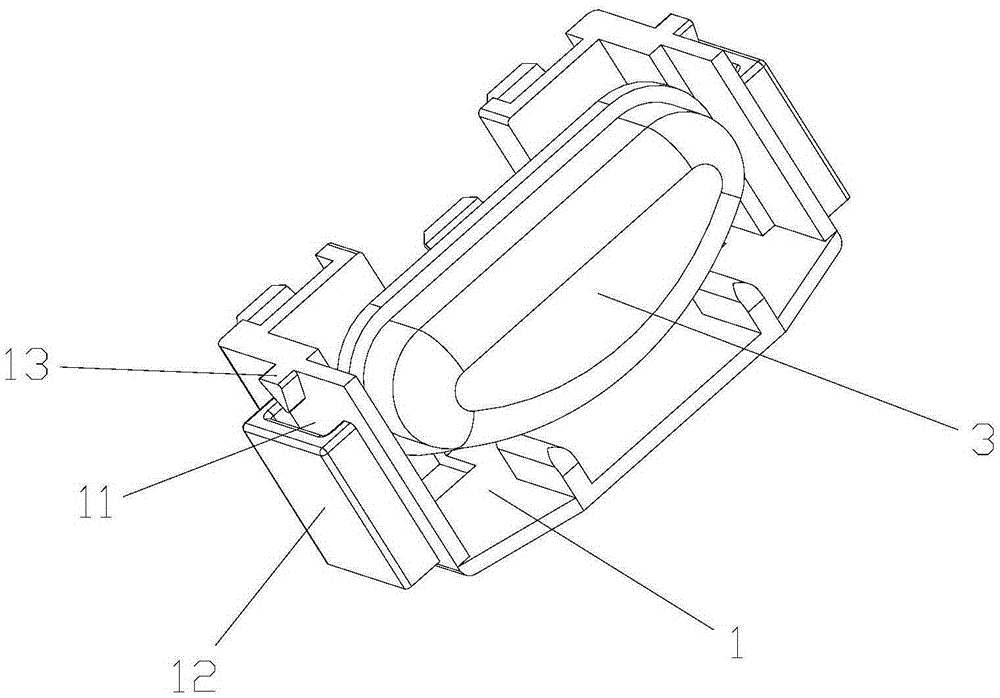

[0025] For this reason, the present invention provides the new installation structure of overload protector (such as three-phase compressor overload protector), as Figure 1-3 shown.

[0026] Specifically, the installation structure of the overload protector of the present invention mainly includes an overload protector shell 1 and an overload protector bracket 2 . Wherein, the overload protector 3 is fixed in the overload protector shell 1, and the overload protector shell 1 and the overload protector bracket 2 are installed together, and the overload protector bracket 2 is fixed on the installation parts such as the inner cover of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com