Buffering and energy absorption filling pipe

A technology of filling tubes and hollow tubes, which is applied to springs made of plastic materials, springs/shock absorbers, elastic shock absorbers, etc., can solve the problems of poor energy absorption effect of foam aluminum filling tubes, and achieve strong energy absorption capacity , crushing force and energy absorption capacity improvement, the effect of independent bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

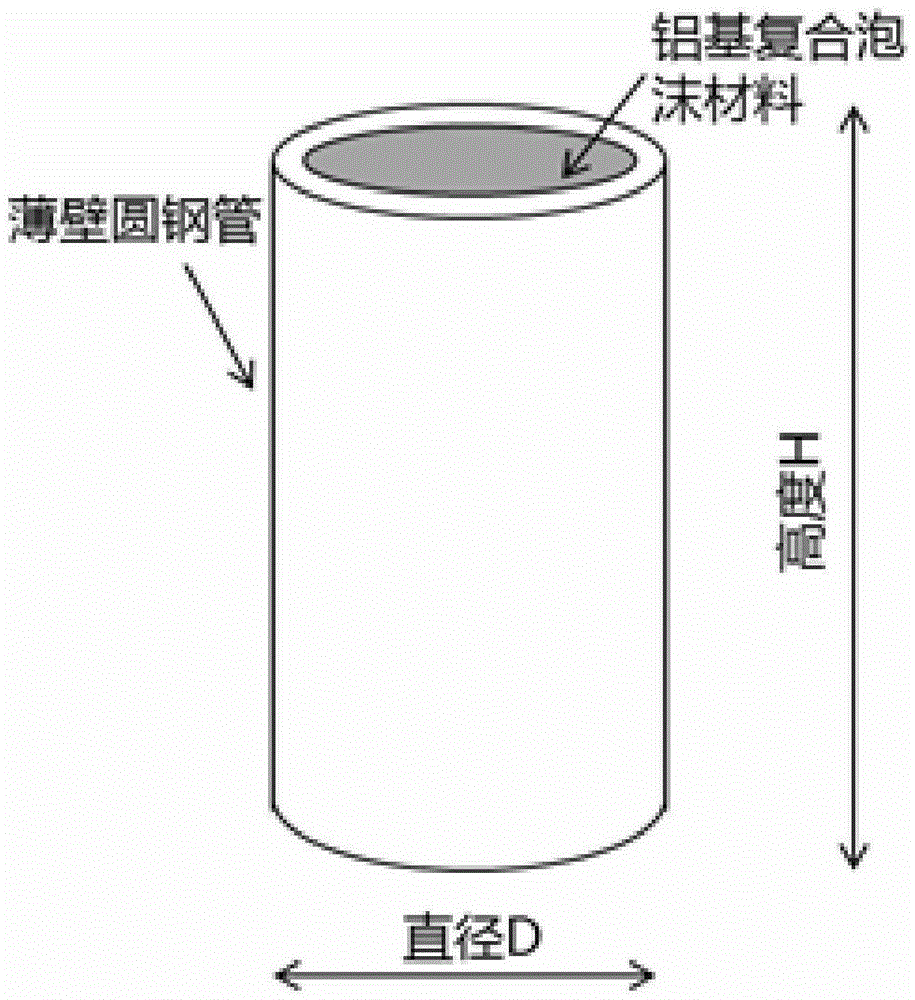

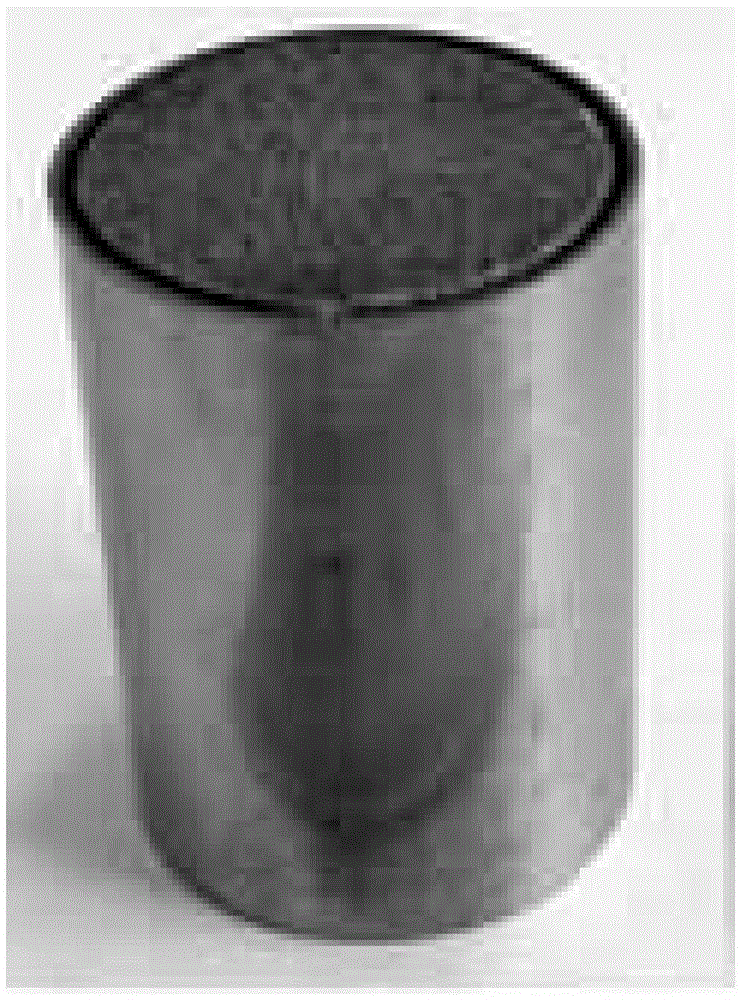

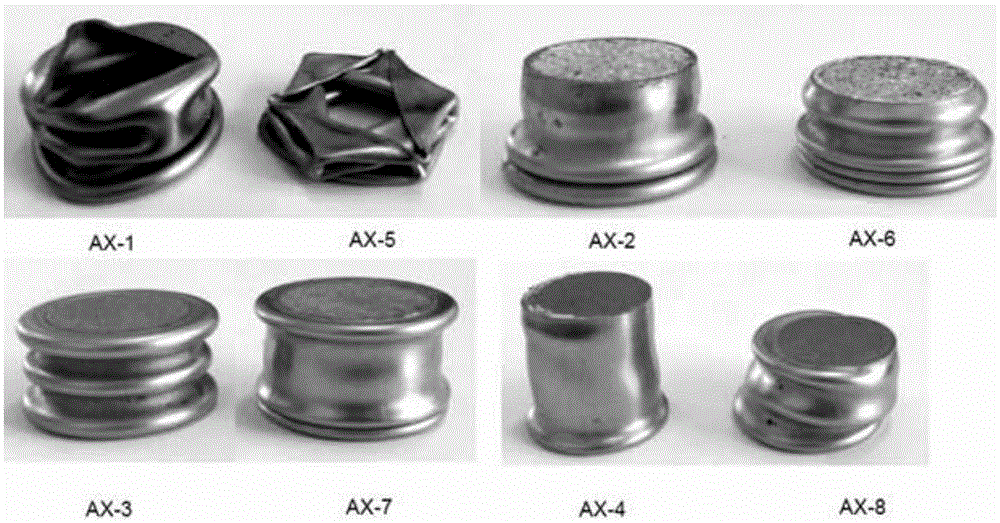

[0019] Specific Embodiment 1: The energy-absorbing buffer tube of this embodiment is composed of a 304 stainless steel hollow tube with a wall thickness of 1 mm and aluminum-based composite foam filled in the hollow tube.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the aluminum-based composite foam is a hollow microsphere aluminum-based composite foam with a pore size of 80 μm or a hollow microsphere aluminum-based composite foam with a pore size of 150 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the density of the hollow microsphere aluminum-based composite foam material with a pore size of 80 μm is 1.0085 g / cm 3 . It is the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com