A drip-proof structure

An anti-drip and valve body technology, which is applied in the direction of control valves, functional valve types, engine components, etc., can solve problems such as the inability to limit the fluid flow direction and the inability of the water meter to measure the flow rate, and achieve the effect of preventing fluid backflow and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

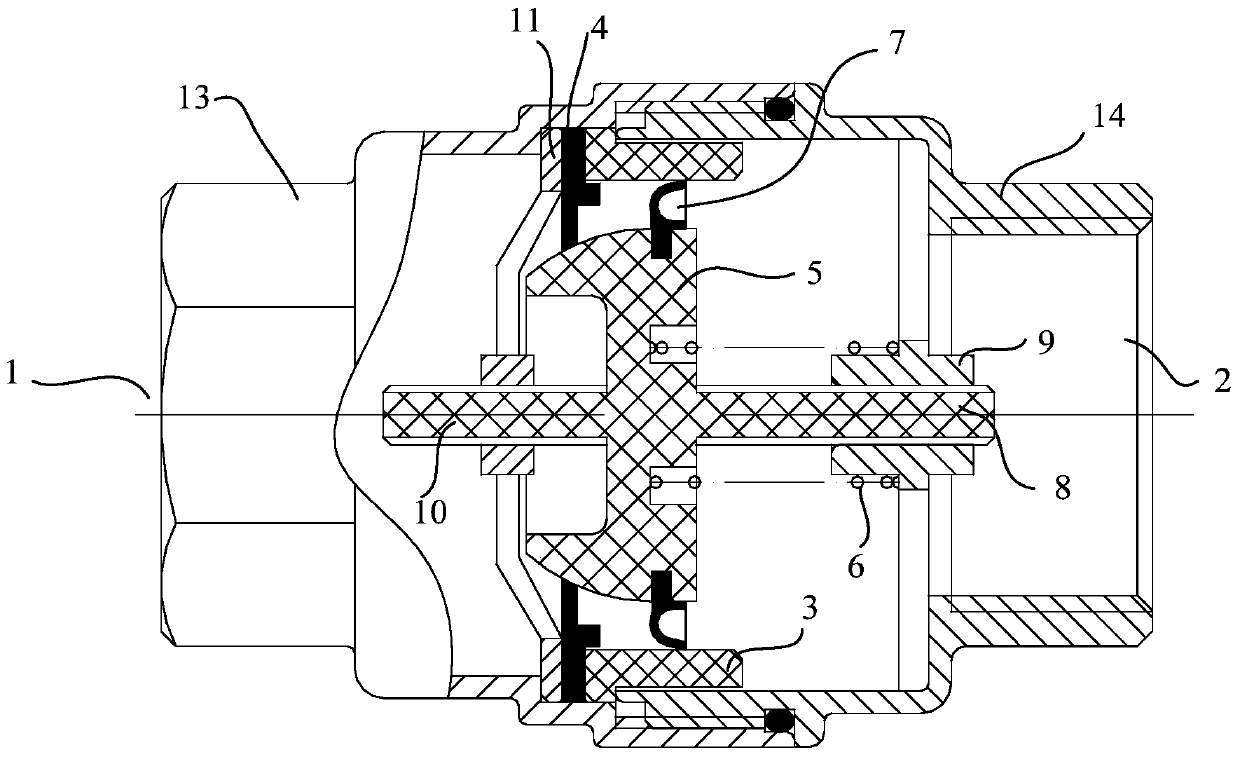

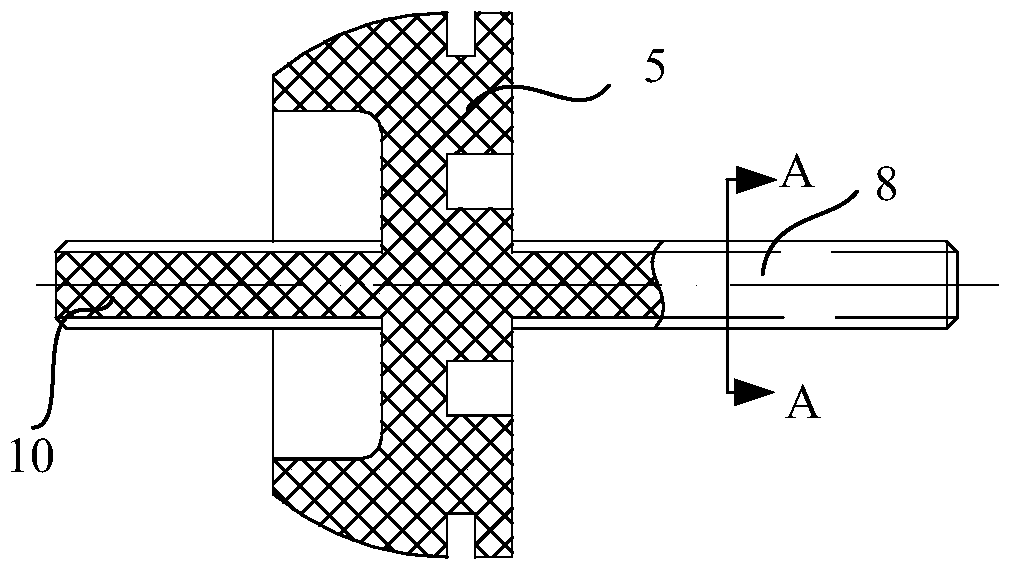

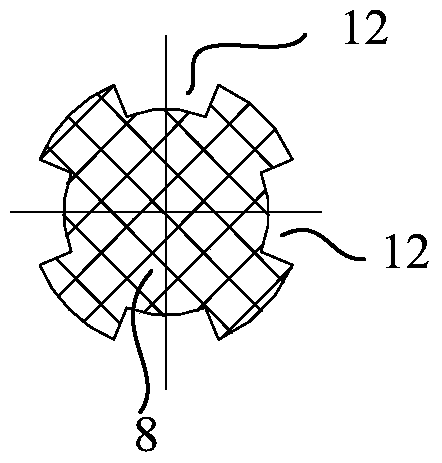

[0025] Such as figure 1 As shown, an anti-drip structure includes a valve body, the valve body is provided with a water inlet 1 and a water outlet 2, a valve seat 3 and a rubber pad 4 are fixed on the inner wall of the valve body, and a valve plate 5 is also provided inside the valve body , the valve plate 5 reciprocates along the water flow direction under the action of water pressure and the return device 6. When the valve plate 5 contacts the valve seat 3, it is a radial seal. When the valve plate 5 contacts the valve seat 3 and the rubber pad 4 at the same time, the rubber A sealed space is formed between the gasket 4, the valve seat 3 and the valve plate 5. When the water outlet 2 does not flow, the valve plate 5 is close to the rubber pad 4 under the action of the return device 6, and a sealed space is formed between the valve plate 5, the valve seat 3 and the rubber pad 4. When dripping occurs, due to the water outlet 2 The pressure drops, and the valve plate 5 moves t...

Embodiment 2

[0035] This embodiment is basically the same as the anti-drip structure in Embodiment 1, including a valve body, which is provided with a water inlet 1 and a water outlet 2, and a valve seat 3 and a rubber pad 4 are fixed on the inner wall of the valve body. A valve plate 5 is also provided, and the valve plate 5 reciprocates along the water flow direction under the action of water pressure and the return device 6. When the valve plate 5 contacts with the valve seat 3, it is a radial seal. 4 When in contact at the same time, a sealed space is formed between the rubber pad 4, the valve seat 3 and the valve plate 5.

[0036] The difference is that the specific structure of the valve body is not limited, the specific location of the water inlet 1 and the water outlet 2 is not limited, the specific structure and fixing method of the valve seat 3, rubber pad 4, and valve plate 5 are not limited, and the valve plate 5 The sealing scheme between the valve seat 3 and the valve seat 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com