A New Tire Vertical Pressure Distribution Function, Algorithm and Test System

A pressure distribution and tire technology, applied in the algorithm and test system, the new tire vertical pressure distribution function field, can solve the problems of low precision, complex model, can not well reflect the tire rolling direction, etc., to facilitate testing and calculation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

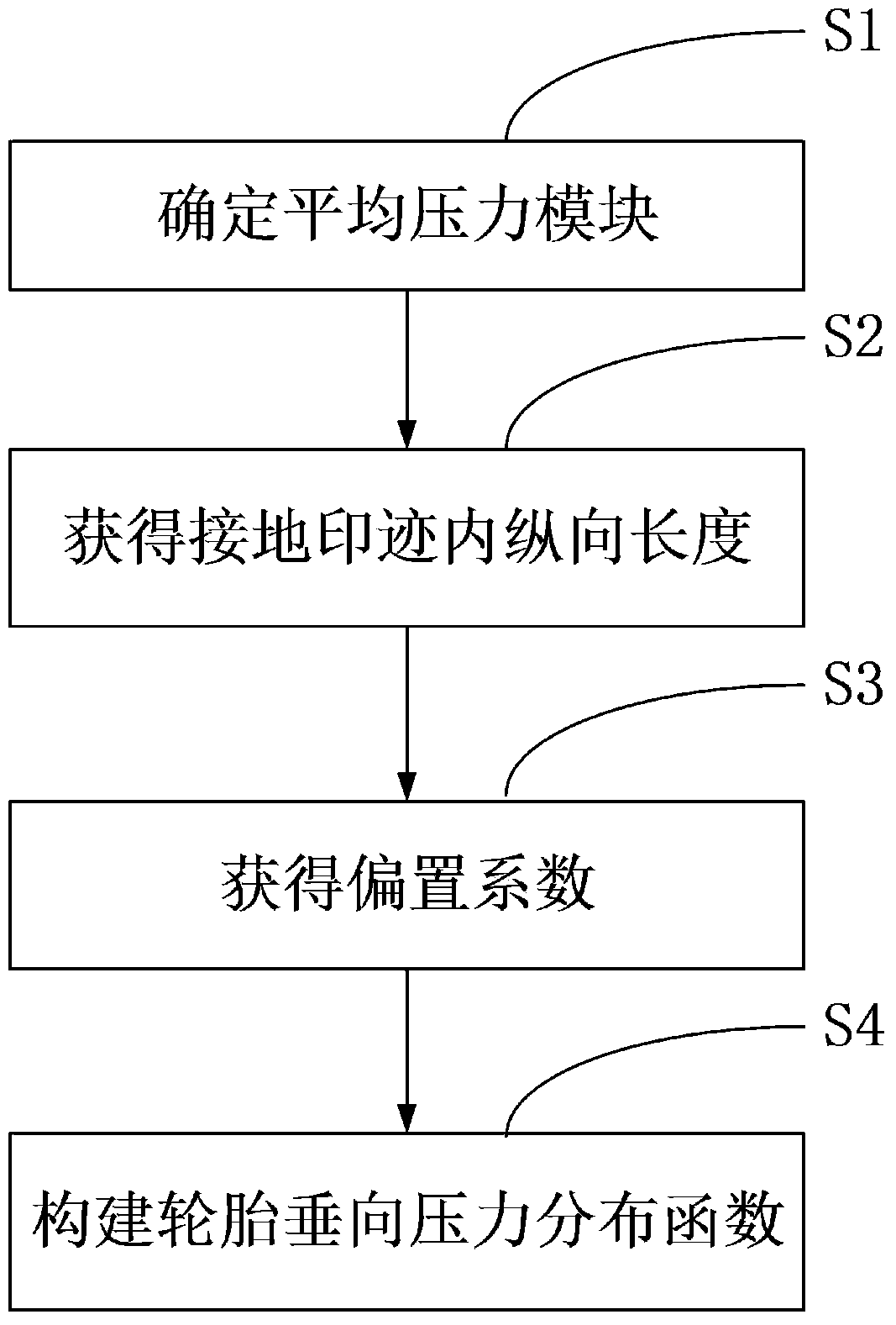

[0039] Such as figure 1 As shown, the present invention provides a tire vertical pressure distribution algorithm, including the following steps:

[0040] Step S1, determine the average pressure module;

[0041] Step S2, obtaining the longitudinal length in the grounding footprint;

[0042] Step S3, obtain the bias coefficient; and

[0043] Step S4, construct the tire vertical pressure distribution function.

[0044] Wherein, the average pressure module is determined in the step S1, that is, the average pressure module is determined by the tire structure and material properties.

[0045] And the bias coefficient relates to the wheel model and acceleration, and is suitable to be obtained by measurement by a measurement unit, such as but not limited to a Tekscan pressure distribution measurement unit.

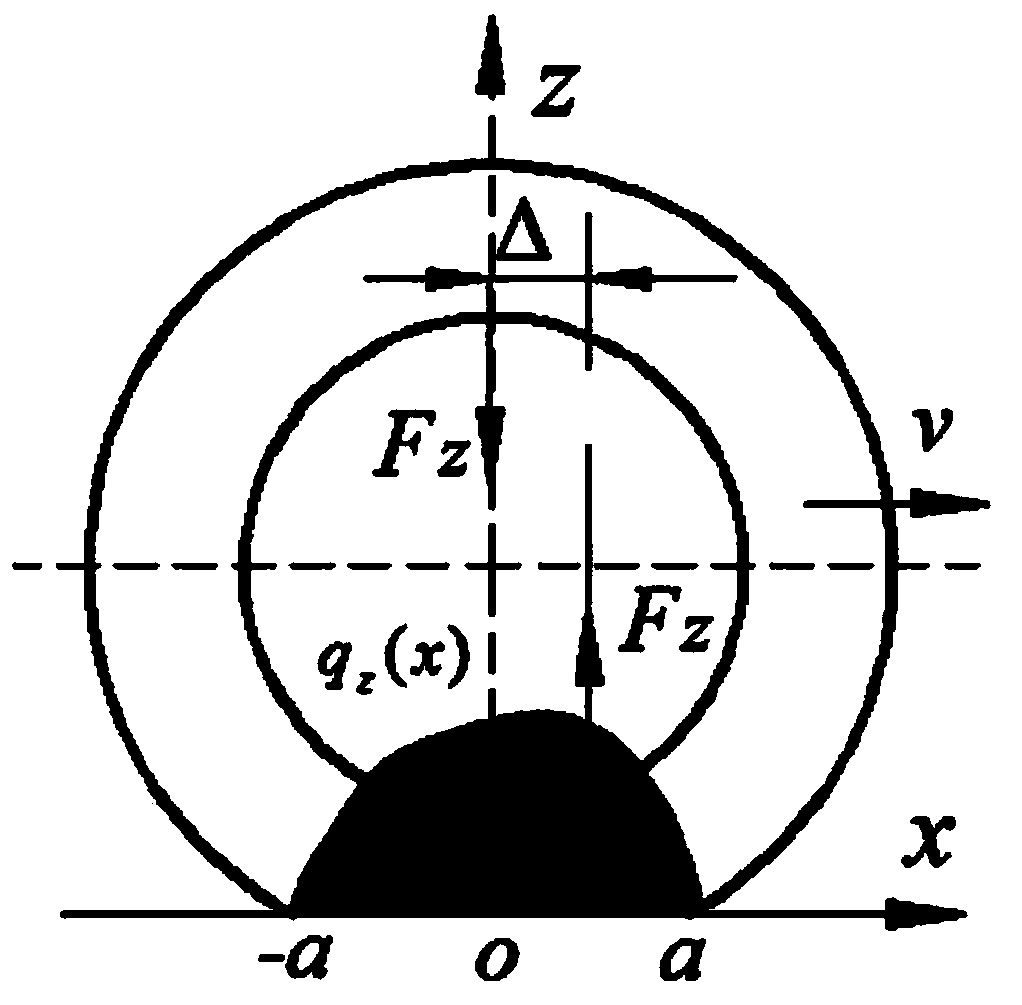

[0046] Such as figure 2 with image 3 As shown, the vertical pressure distribution of the tire is

[0047] Where Is the average pressure module, where G is the tire shear modulus, h is the ...

Embodiment 2

[0052] Such as Figure 4 As shown, on the basis of Example 1, the present invention also provides a tire vertical pressure distribution test system, including:

[0053] Pressure distribution function building module, average pressure determination module, longitudinal length calculation module in grounding footprint, and measurement module suitable for obtaining offset coefficient;

[0054] The pressure distribution function construction module is adapted to be connected with the average pressure determination module, the longitudinal length calculation module in the grounding footprint and the measurement module to construct the tire vertical pressure distribution function;

[0055] And through the tire vertical pressure distribution function to test the tire vertical pressure distribution.

[0056] Such as figure 2 with image 3 As shown, the vertical pressure distribution of the tire is

[0057] Where Is the average pressure module, where G is the tire shear modulus, h is the sid...

Embodiment 3

[0063] Such as figure 2 with image 3 As shown, the present invention also provides a tire vertical pressure distribution function,

[0064] The vertical pressure distribution of the tire is

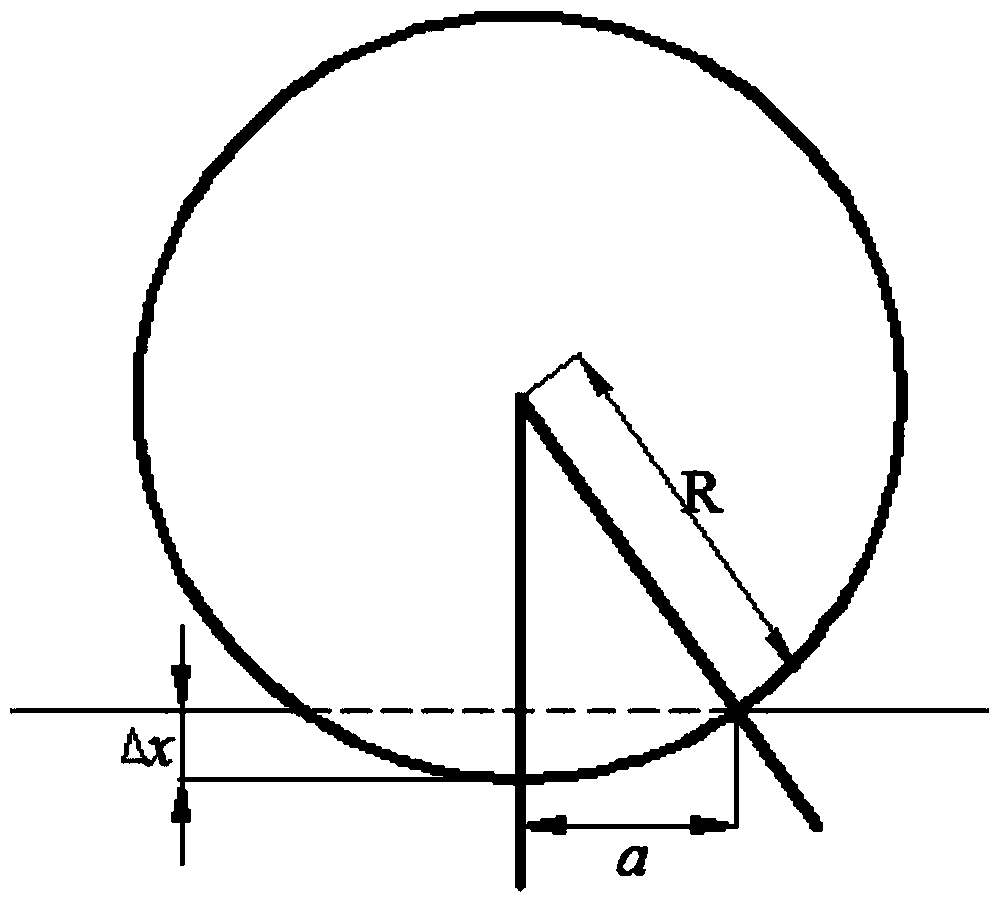

[0065] Where Is the average pressure module, where G is the tire shear modulus, h is the sidewall height, and R is the tire radius;

[0066] Δ is a bias coefficient, the bias coefficient relates to the wheel model and acceleration, Δ∈[-0.3, 0.3]; the bias coefficient is suitable for measurement by a Tekscan pressure distribution measurement unit.

[0067] Is a parabolic distribution module, where a is half of the longitudinal length in the grounding footprint, It is the longitudinal relative coordinate value in the grounding footprint.

[0068] The longitudinal length of the grounding footprint 2a is suitable for passing the vertical stiffness k z And vertical load F z Solve, namely

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com