Electronic device shell, manufacturing method of electronic device shell and electronic device

A technology of electronic devices and manufacturing methods, applied in the direction of casings/cabinets/drawer parts, etc., can solve the problems of affecting user experience, high cost, inconvenient buttoning, etc., to improve user experience and reduce use thickness , to ensure the effect of metal appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

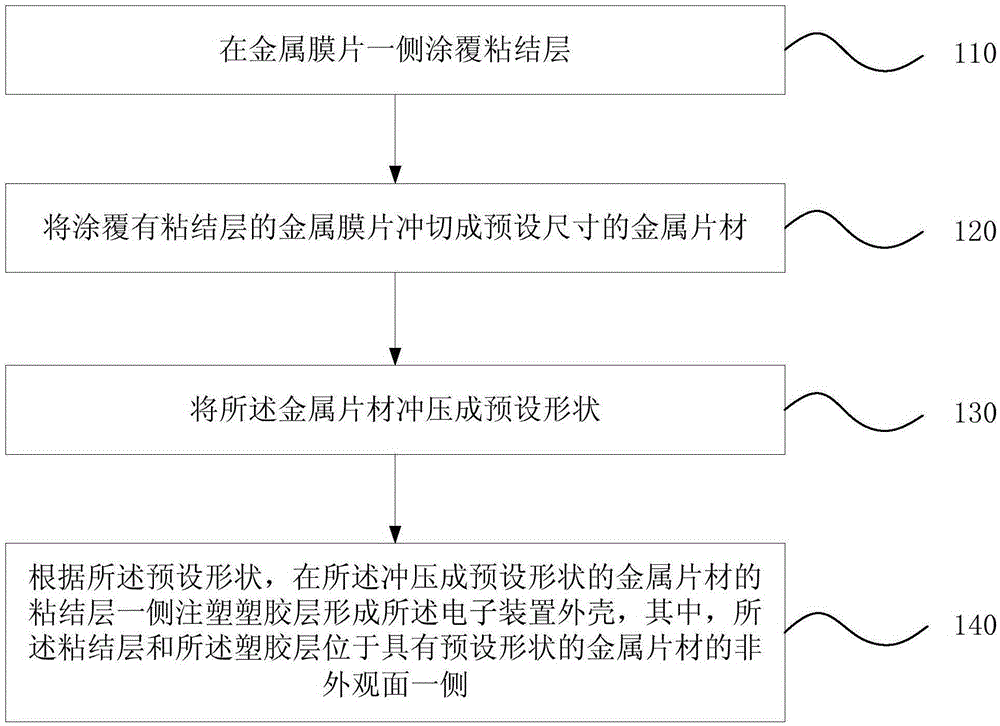

[0021] figure 1 It is a flow chart of a method for manufacturing an electronic device housing provided in Embodiment 1 of the present invention, and the method specifically includes the following steps:

[0022] Step 110, coating an adhesive layer on one side of the metal diaphragm.

[0023] Step 120 , punching the metal diaphragm coated with the adhesive layer into metal sheets of predetermined size.

[0024] The metal diaphragm coated with the adhesive layer is punched into metal sheets of predetermined size according to the size of the housing of the electronic device to be processed.

[0025] Step 130, stamping the metal sheet into a preset shape.

[0026] Specifically, the metal sheet punched into a preset size is put into a punching die, and punched into a preset shape, and the preset shape is the same as the shape of the housing of the electronic device to be processed. Optionally, multi-stage stamping can also be carried out due to the difference in appearance chara...

Embodiment 2

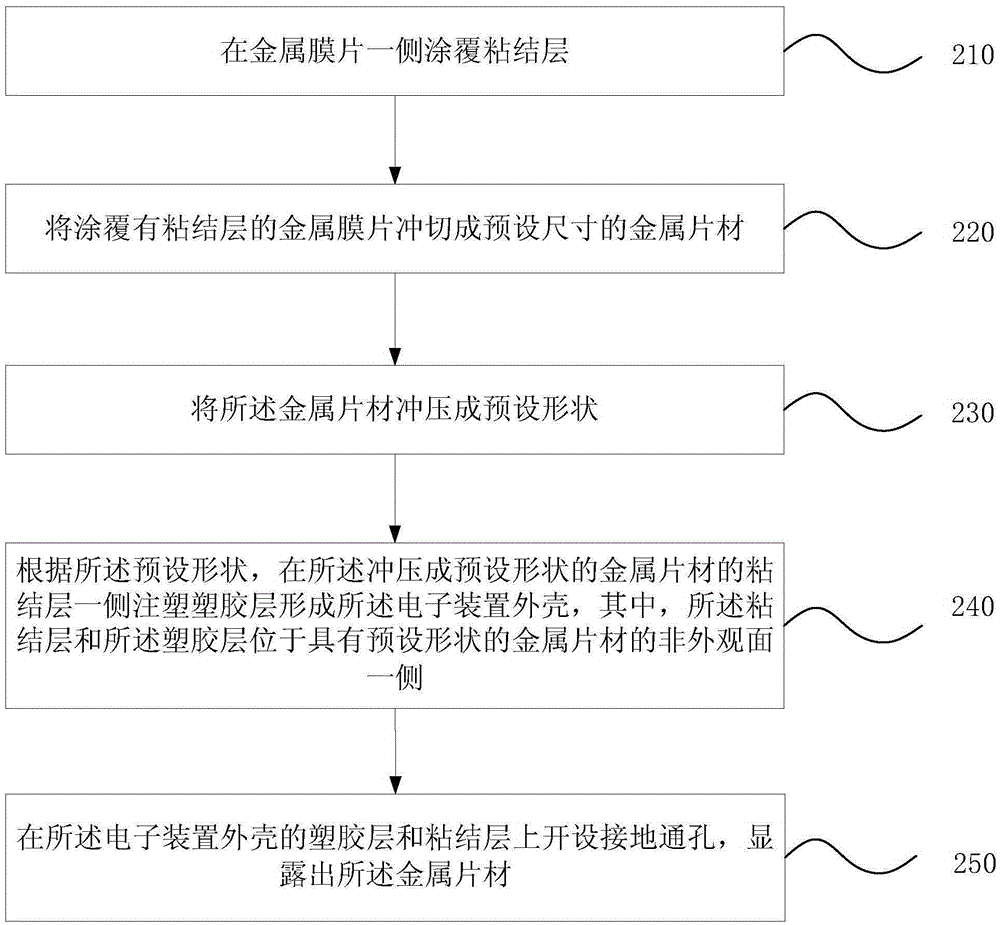

[0043] figure 2 It is a flow chart of a method for manufacturing an electronic device casing provided by Embodiment 2 of the present invention. This embodiment is based on the embodiment. After step 140, it preferably further includes: A ground via hole is opened on the junction layer to expose the metal sheet. see figure 2 , the method specifically includes the following steps:

[0044] Step 210, coating an adhesive layer on one side of the metal diaphragm;

[0045] Step 220, punching the metal diaphragm coated with the adhesive layer into a metal sheet of a predetermined size;

[0046] Step 230, stamping the metal sheet into a preset shape;

[0047] Step 240, according to the preset shape, inject a plastic layer on one side of the adhesive layer of the metal sheet punched into the preset shape to form the housing of the electronic device, wherein the adhesive layer and the plastic layer On the non-appearance side of a metal sheet with a predetermined shape.

[0048] ...

Embodiment 3

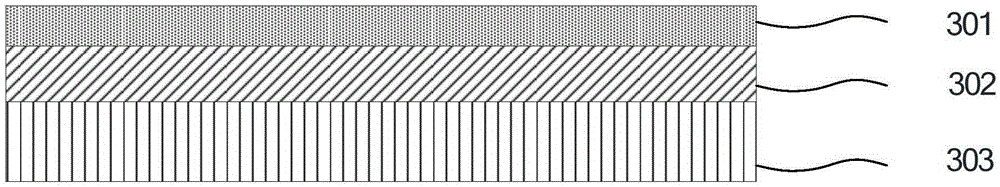

[0052] image 3 It is a schematic cross-sectional view of an electronic device housing in Embodiment 3 of the present invention. The electronic device housing of this embodiment can be made by any method provided in this embodiment. See image 3 , the electronic device housing includes: a metal sheet 301 with a preset shape, an adhesive layer 302 and a plastic layer 303; wherein, the non-appearance surface of the metal sheet 301 with a preset shape passes through the adhesive layer 302 is connected to the plastic layer 303 , and the shape of the plastic layer 303 matches the preset shape of the metal sheet 301 .

[0053] The technical solution of this embodiment provides an electronic device housing, which includes a metal sheet with a preset shape, an adhesive layer, and a plastic layer; wherein, the non-appearance of the metal sheet with a preset shape The surface is connected to the plastic layer through the adhesive layer, and the shape of the plastic layer matches the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com