Manufacturing apparatus of sheet-welded body and method of manufacturing sheet-welded body

A technology of sheet welded body and manufacturing equipment, which is applied in the field of manufacturing equipment of sheet welded body and sheet welded body, can solve the problems of no record, etc., and achieve the effect of suppressing energy loss and high-efficiency manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described based on preferred embodiments thereof with reference to the drawings.

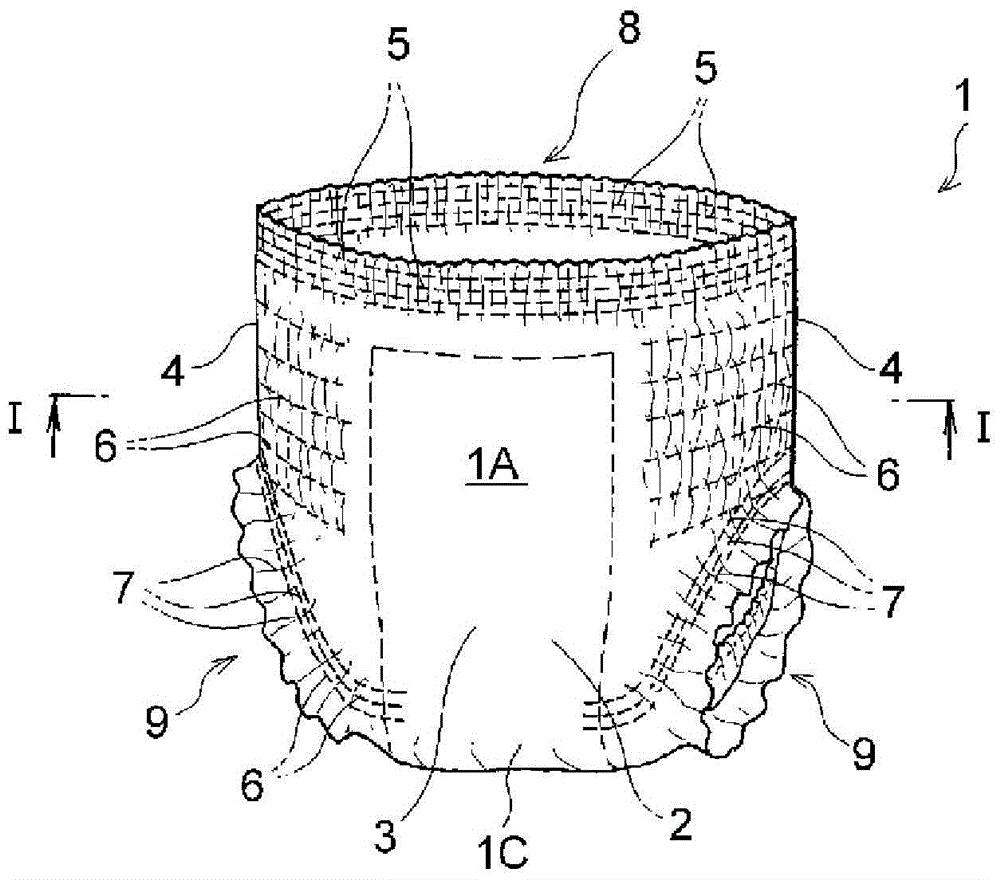

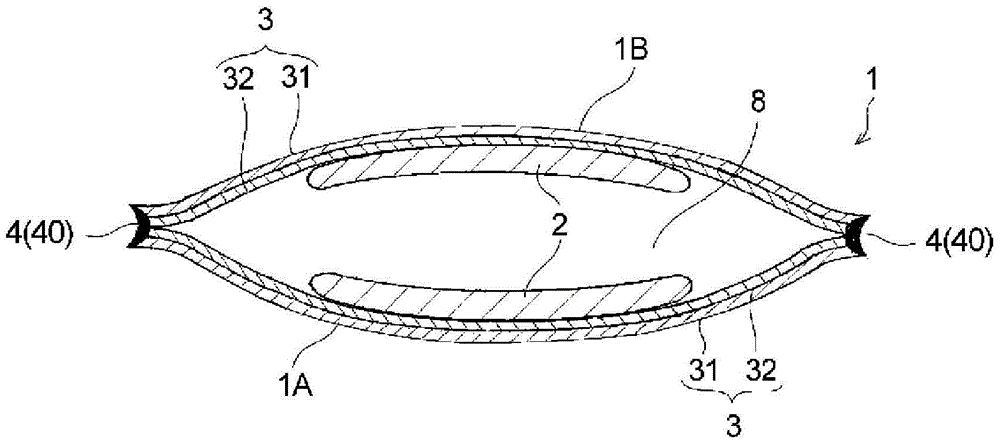

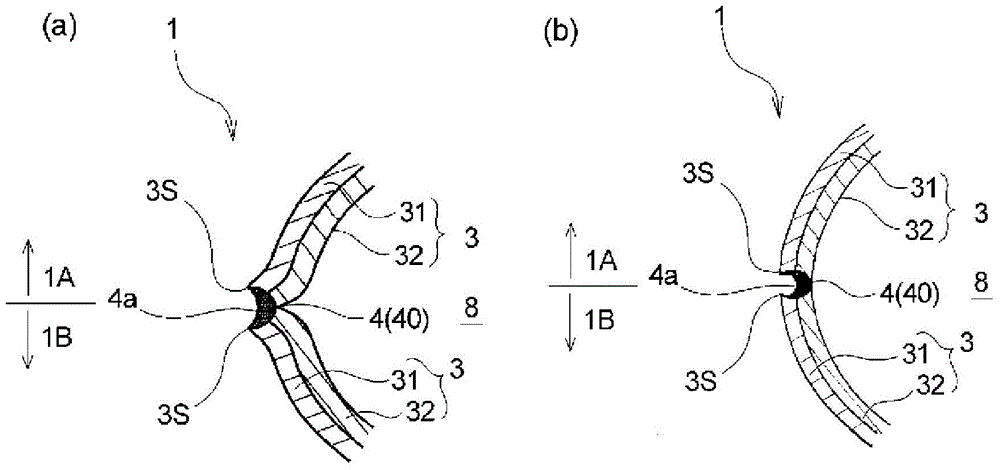

[0027] Here, the sheet-welded body manufactured by the manufacturing apparatus of this embodiment and the manufacturing method of this embodiment, that is, a sheet-welded body having a sealed edge portion in which a plurality of sheets are welded in a state where their edges are overlapped, is, for example, figure 1 and figure 2 Shown is a pants-type disposable diaper 1 including an exterior body 3 having a pair of side seal portions 4 , 4 . First, based on Figure 1 ~ Figure 3 The underpants type disposable diaper 1 will be described.

[0028] Such as figure 1 and figure 2 As shown, the diaper 1 is a pants-type disposable diaper, which has: an absorbent main body 2; The side edges of the exterior body 3 in the side portion 1A are joined to the side edges of the exterior body in the back side portion 1B to form a pair of side seals 4, 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com