Method and device for low-gravity 3D printing of molten iron alloy

A 3D printing and iron alloy technology, applied in the direction of additive processing, etc., can solve problems such as complex process, troublesome removal, poor surface quality, etc., and achieve the effect of improving product quality, avoiding oxidation, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

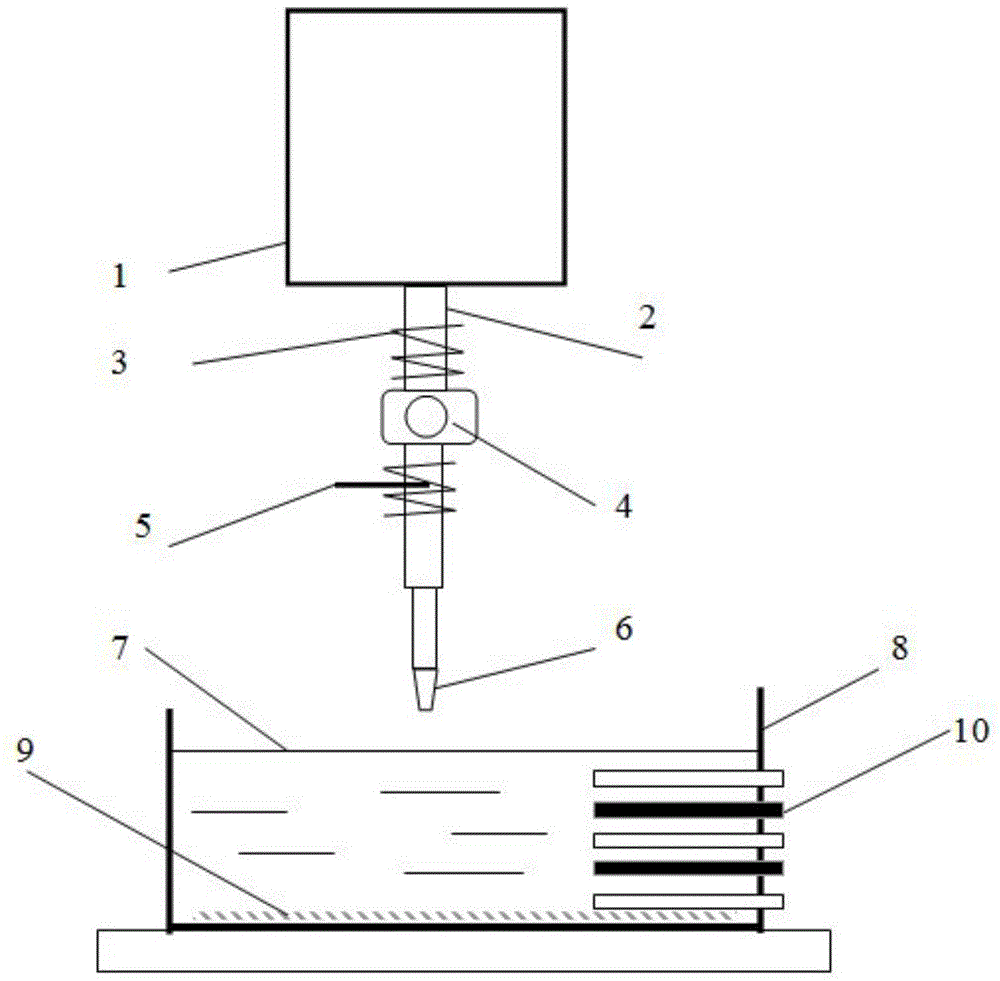

Embodiment 1

[0016] For the molten ferroalloy, the control temperature in the liquid metal container, pipeline and intermediate liquid metal bag is 1520-1540°C, and the temperature of the molten metal zinc is 440-450°C. The metal flow rate is controlled to be 1ml / s, the horizontal movement rate of the molten ferroalloy printing nozzle 6 is 200mm / s, and each vertical movement distance is 2mm. It can realize the printing and manufacturing of plates and components with a thickness of 2.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com