Electronically-controlled tin melting device

An electronic manipulation and tin melting technology, applied in auxiliary devices, soldering irons, metal processing equipment, etc., can solve problems such as incomplete tin melting points, and achieve the effect of avoiding inconsistent standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, content of the invention will be further described:

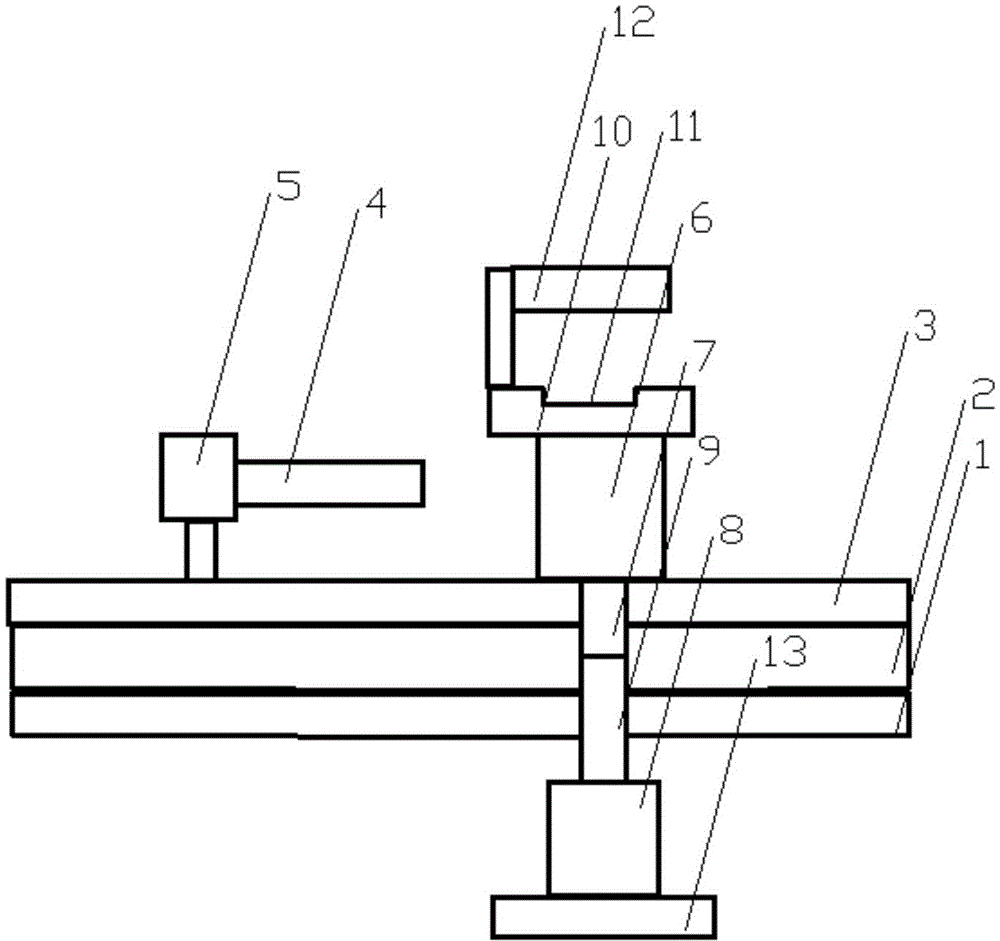

[0011] refer to figure 1 As shown, the tin melting device under electronic manipulation includes a base 1, on which a block-shaped support block 2 is installed, and a conveyor belt 3 is installed on the support block 2, and a conveyor belt 3 is installed above the conveyor belt 3. The hydraulic gripper 4 driven by the hydraulic cylinder 5 is equipped with a square platform 6 on the conveyor belt 3, the bottom of the square platform 6 is connected with a connecting rod 7, the connecting rod 7 is connected with the motor shaft 9 of the motor 8, and the square platform 6 is installed to be The tin-melting component placement frame 10 is equipped with a concave hole 11 matching the outline of the tin-melting component on the pending-tin component placement frame 10, and an automatic tin-discharging electric soldering iron 12 is erected above the pending-tin component placem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com