Belt pressing device of grinding belt of one-circle-twice-grinding deburring machine and working method

A technology of abrasive belt and grinding, which is applied in the direction of grinding machines, manufacturing tools, abrasive belt grinders, etc. It can solve the problems of abrasive belt out of the wheel and the failure of the whole machine to achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

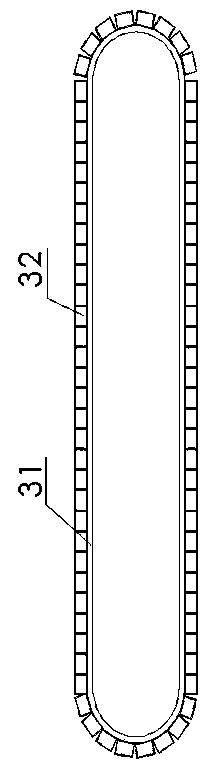

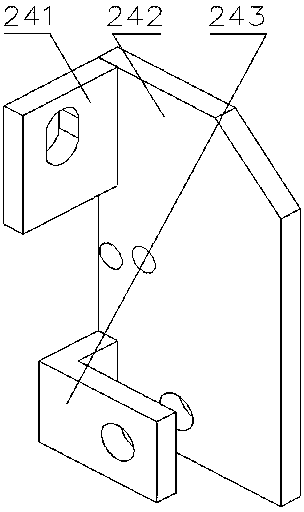

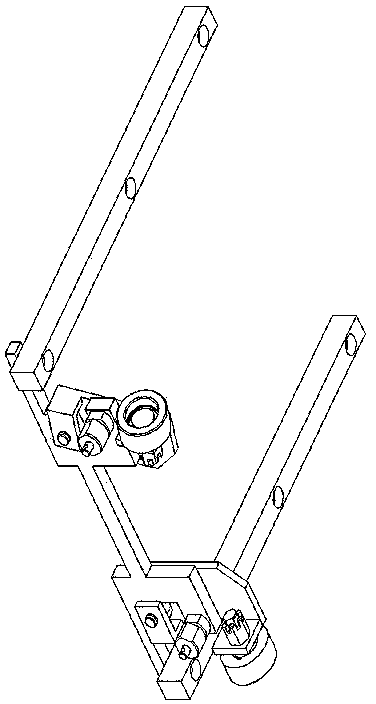

[0014] Embodiment 1: with reference to attached Figure 1-5 . An abrasive belt pressing device for a one-turn two-grinding deburring machine. The driven wheel 1 and the driving wheel 4 are covered with an abrasive belt 3 and form a circular abrasive belt transmission mechanism that rotates horizontally. It is located on the opposite side of the driven wheel 1 and the driving wheel 4. The lower end surface or the upper end surface of the abrasive base belt 3 is provided with a pin type pinch roller assembly 2 . The pin pulley assembly 2 is composed of a roller 21, a wheel shaft 23, a connecting plate 24, a latch 25 and a roller base 26. The two rollers 21 are respectively connected to the two connecting plates 24 through the wheel shaft 21. The middle parts of the two connecting plates 24 The bolts 25 are fitted with the roller bases 26 respectively, and the lower parts of the two connecting plates 24 are respectively hinged with the roller bases 26 by pivot pins. The upper p...

Embodiment 2

[0015] Embodiment 2: with reference to attached Figure 6 . On the basis of embodiment 1, a kind of working method of two grinding deburring machine abrasive belt pressure belt devices in one circle, the deburring machine abrasive belt 3 that is horizontally sleeved on the driven wheel 1 and the driving wheel 4 is driven by the driving wheel 4 When rotating horizontally, the four pinch rollers in the two groups of pin-type pinch roller assemblies 2 respectively hold the lower end surface or the upper end surface of the abrasive belt 3 and rotate under the drive of the lower end surface or the upper end surface of the abrasive belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com