A special insulating socket based on electric wrench

An electric wrench, insulating sleeve technology, applied in the direction of wrenches, power tools, screwdrivers, etc., can solve the problems of affecting work efficiency, arbitrary adjustment, and difficult angle fine-tuning, etc., to meet the needs of work and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] see figure 1 , figure 1 It is a traditional insulating rod connecting sleeve. During operation, it is necessary to align the electric wrench head with the bolt in the parallel groove clamp. This requires particularly high precision for adjusting the angle of the connection head. If the operator on the ground cannot accurately adjust to the required angle, it is necessary to continuously Loosen and tighten the bolts on the sleeve to adjust, which brings great inconvenience to the operator and has a strong impact on work efficiency.

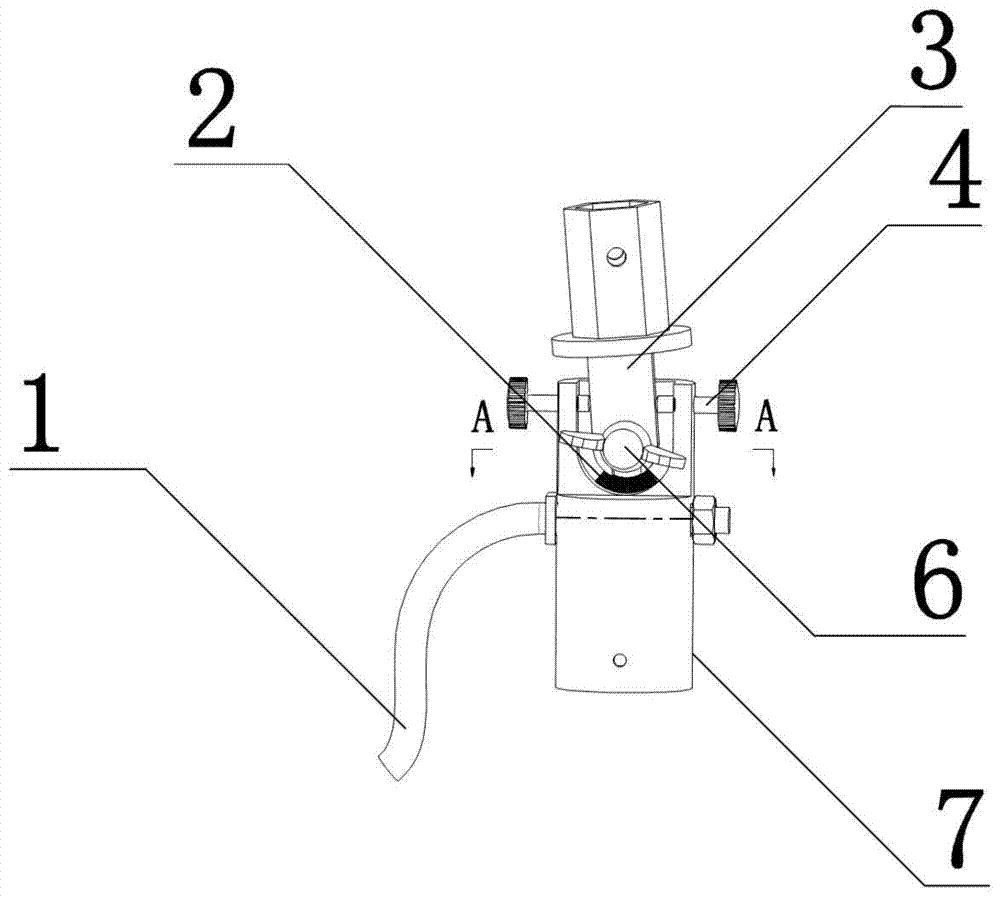

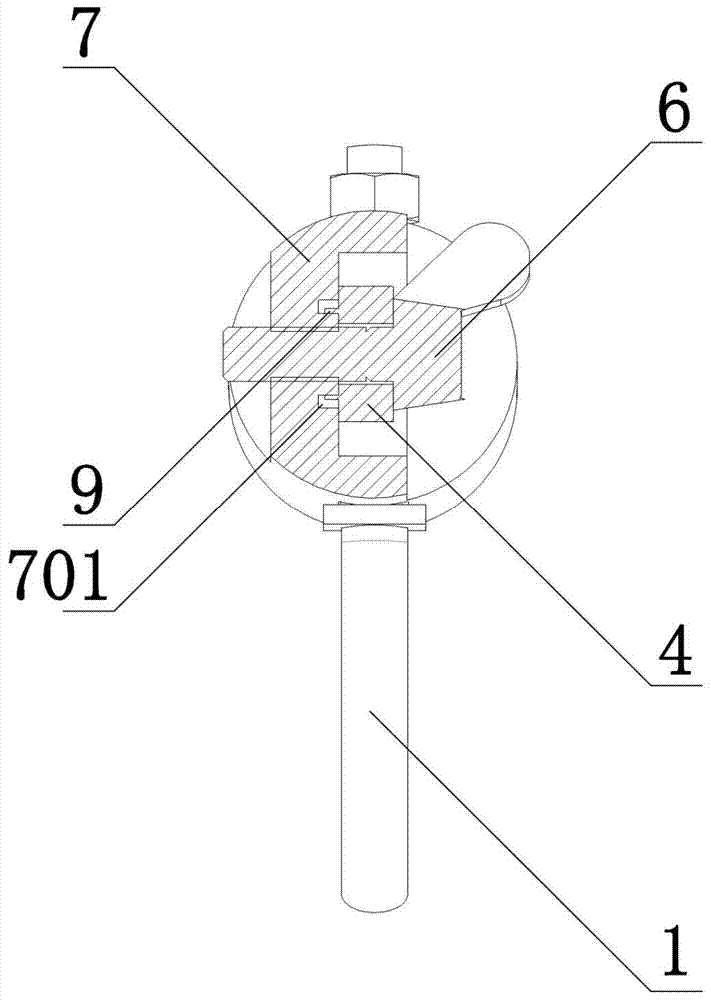

[0026] see figure 2 , figure 2 It is a structural schematic diagram of a special insulating sleeve based on an electric wrench of the present invention. A special insulating socket based on an electric wrench, including a first socket 4 and a second socket 7, the upper end of the first socket 4 is fixed with the electric wrench, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com