High-speed pantograph head with double contact strips

A technology of pantographs and double slides, applied in current collectors, electric vehicles, power collectors, etc., can solve the problems of no use value and inability to meet the needs of current collection, and achieve light weight, improved followability, and increased vibration frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

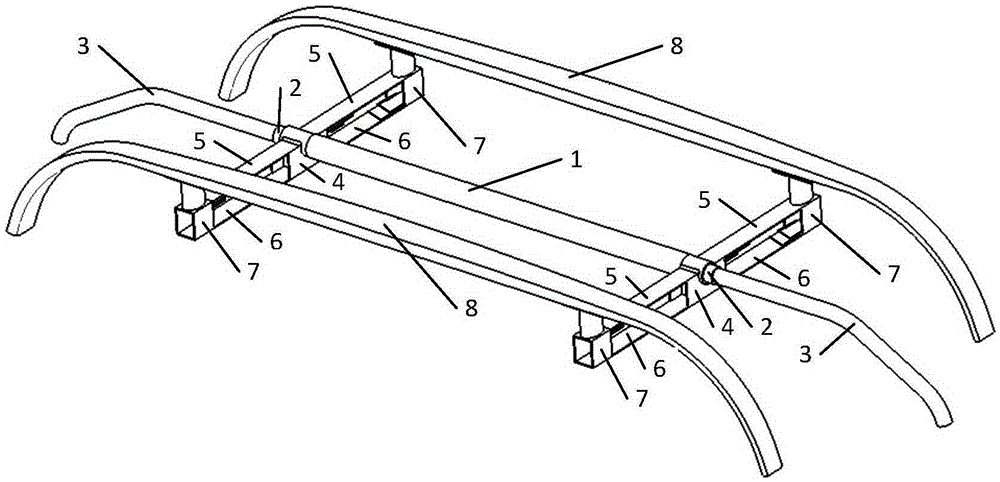

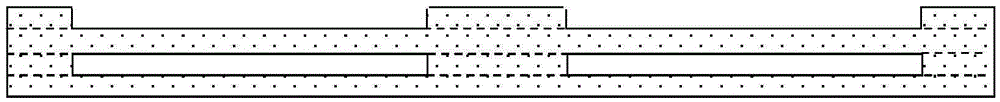

[0017] see figure 1 and figure 2 , the casing 2 is inserted into the top pipe 1, the two bow angles 3 are respectively inserted into the two ends of the casing 2, the spring support 4 is fastened to the two ends of the casing 2 and the two bow angles 3 are connected to the casing 2 Consolidation, two groups of spring sheets are symmetrically arranged on both sides of each spring support 4, each group of spring sheets is composed of parallel upper spring sheets 5 and lower spring sheets 6, and the ends of each group of spring sheets are fixedly connected with a A slide plate 8 is fixedly connected to each two slide plate supports 7 on the same side of the top pipe 1 , that is, two slide plates 8 are arranged symmetrically on both sides of the top pipe 1 .

[0018] Further, on the lower spring piece 6 close to the slide plate support 7 and on the upper spring piece 5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com