High-order resonance type quartz tuning fork micro-cantilever and manufacturing method thereof

A high-order resonance type, quartz tuning fork technology, applied in scanning probe microscopy, measuring devices, instruments, etc., can solve the problem of information loss of interaction force and achieve high sensitivity and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

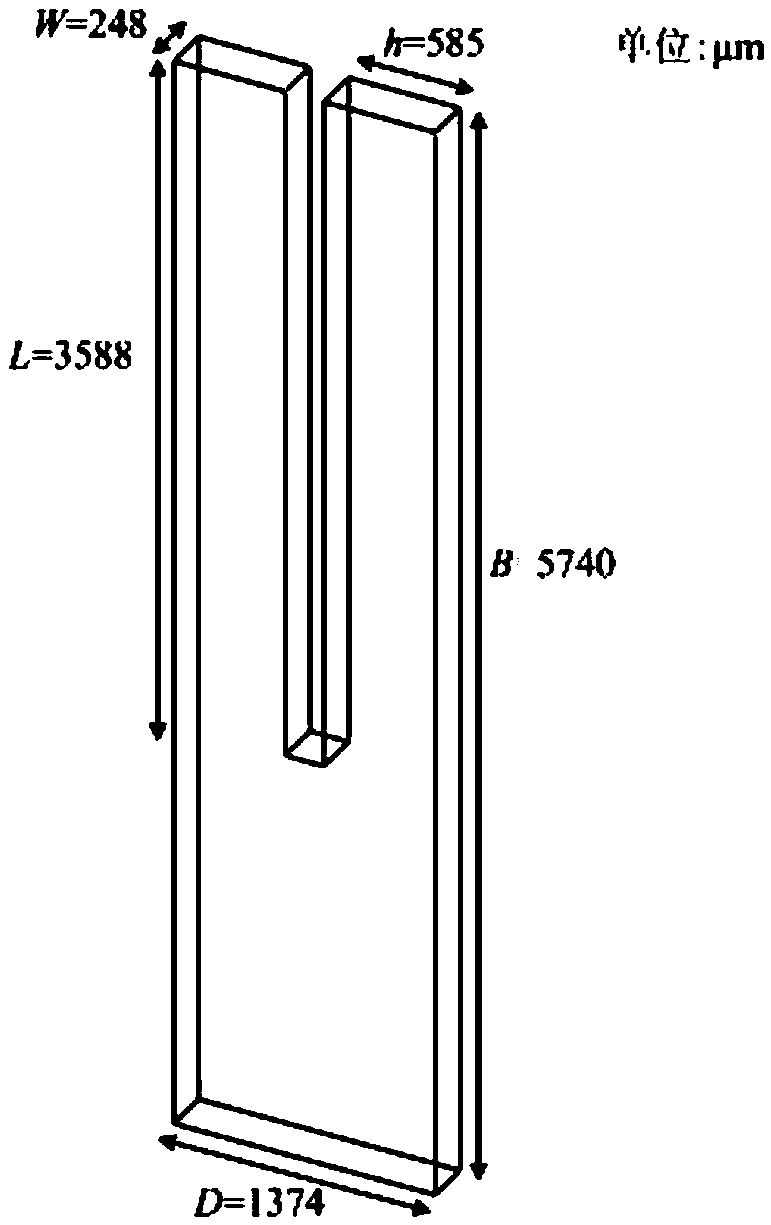

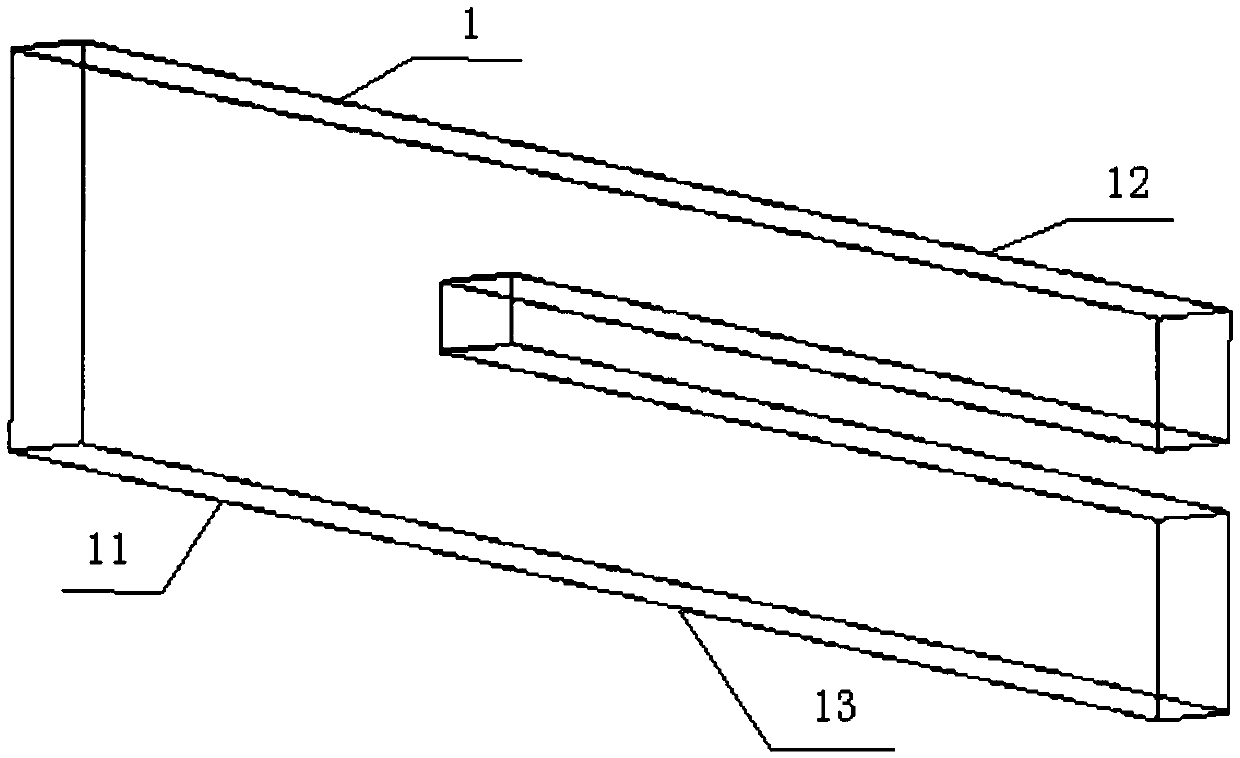

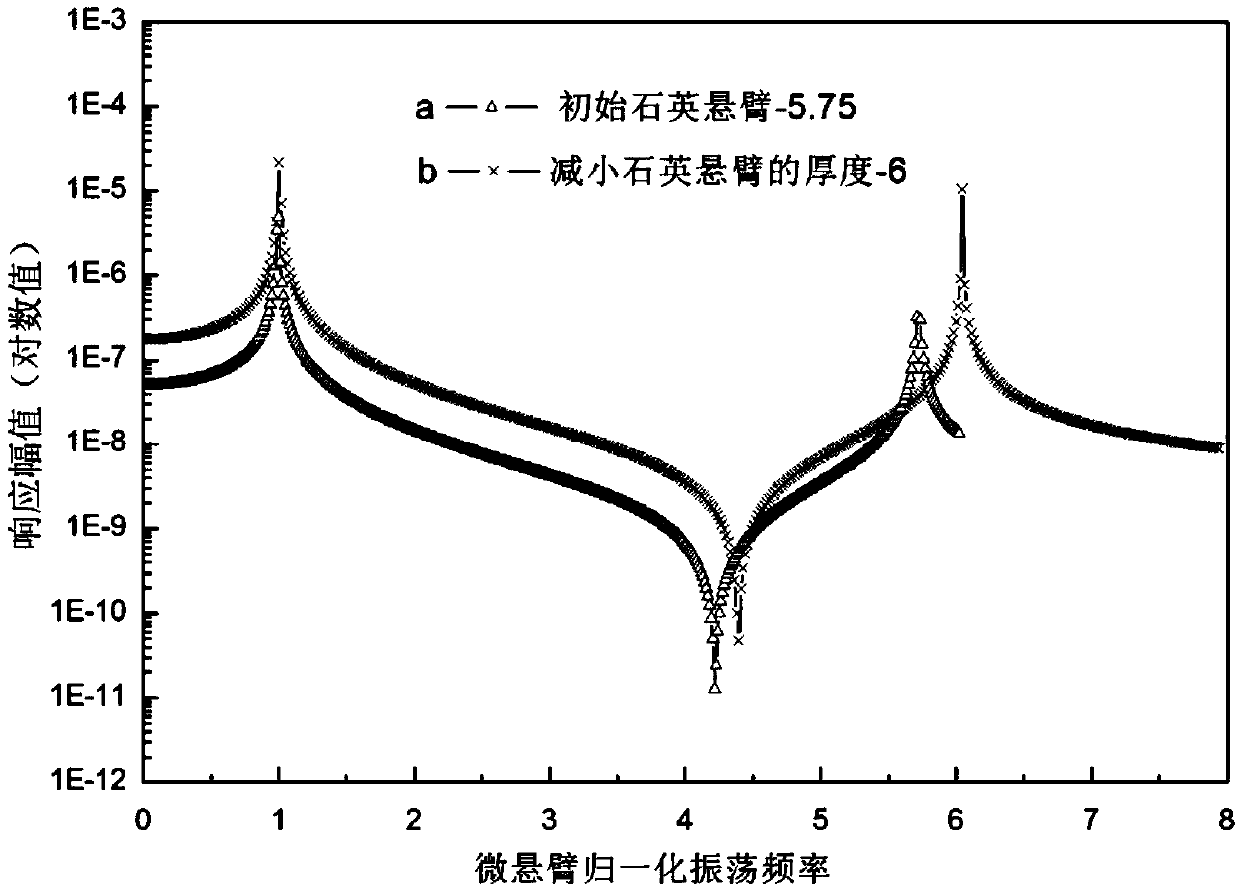

[0032] figure 2 A schematic structural diagram of a high-order resonance type quartz tuning fork micro-cantilever is shown according to an embodiment of the present invention. image 3 It shows the transfer function curves of the existing quartz tuning fork microcantilever and the high-order resonance type quartz tuning fork microcantilever of the present invention under the same magnitude of force.

[0033] Such as figure 2 As shown, the high-order resonance type quartz tuning fork microcantilever includes:

[0034] Quartz tuning fork body 1;

[0035] The quartz tuning fork body 1 includes a tuning fork base 11, a vibrating arm 12 and a fixed arm 13;

[0036] Both the vibrating arm 12 and the fixed arm 13 are connected to the tuning fork base 11;

[0037] The thickness of vibrating arm 12 is dmm less than the thickness of fixed arm 13, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com