Conveying device for steel members

A technology of conveying device and steel components, which is applied to conveyors, transportation and packaging, etc., can solve the problems of inability to adjust, cannot realize transmission in the same production line, and small size range of steel pipe transmission, and achieves the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

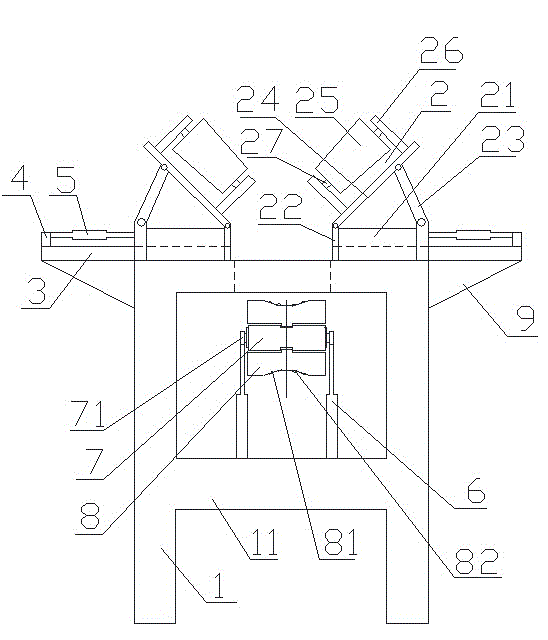

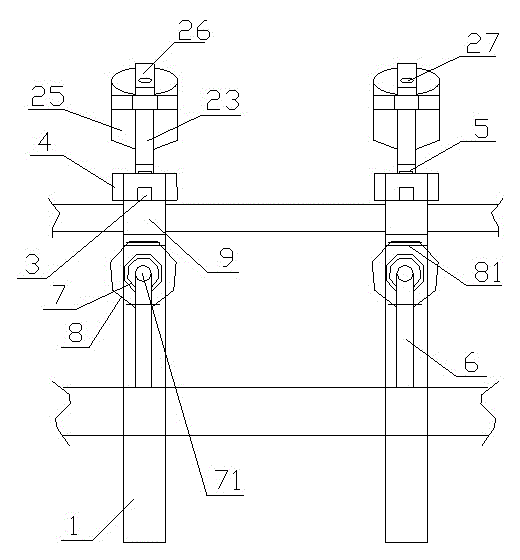

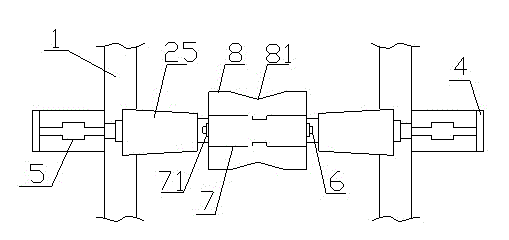

[0015] like figure 1 , figure 2 and image 3 As shown, the conveying device for steel components of the present invention includes a frame 1, the top surface of which is open and a crossbeam 11 is provided at the bottom of the frame 1, and the device also includes a transmission assembly 2, a guide rail 3, a baffle plate 4, and a telescopic pull rod 5 , a telescopic support rod 6, a conveying roller 7 and a conveying belt 8, the guide rail 3 is arranged on both sides of the opening on the top surface of the frame 1 and extends to the outside of the frame 1, and the baffle plate 4 is arranged on the frame 1. The end of the guide rail 3 on the outside of the top surface. The transmission assembly 2 includes a base 21, a short pole 22, a long pole 23, a support frame 24 and a guide wheel 25. The base 21 is arranged on the guide rail 3 and runs along the guide rail. 3 moves, the bottom end of the short pole 22 is arranged on the inner side of the base 21, the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com